Irola ye-RBSiC esetyenziswa kwiKiln

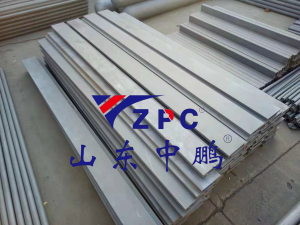

Iiplanga kunye neerola ze-ZPC-RBSiC (SiSiC) zinamandla aphezulu kwaye azinazo iinguqu nokuba kubushushu obuphezulu kakhulu. Kwaye neeplanga zibonisa ubomi obude bokusebenza. Iiplanga zezona fenitshala ze-oven zifanelekileyo kakhulu zokunxitywa ngococeko kunye nokusetyenziswa kwe-porcelain yombane. I-RBSiC (SiSiC) inomoya oshushu ogqwesileyo, ngoko ke iyafumaneka ukonga amandla ngobunzima obuncinci bemoto ye-oven.

Iibhanti ze-silicon carbide kunye neerola zisetyenziswa njengeefreyimu zokulayisha kwii-ovens ezivelisa i-porcelain, kwaye zinokuthatha indawo ye-silicon plate eqhelekileyo ebotshelelwe yi-oxide kunye ne-mullite post kuba zineengenelo ezilungileyo ezifana nokugcina izithuba, ipetroli, amandla kunye nokukhawulezisa ixesha lokudubula, kwaye ixesha lobomi bale zixhobo liphindwe kaninzi kunezinye, yifenitshala ye-oven efanelekileyo kakhulu. I-silicon carbide beam isetyenziswa kakhulu njengezixhobo zokuthwala umthwalo kwi-tunnel kiln, i-shuttle kiln kunye ne-double channels kiln. Ingasetyenziswa njengefenitshala ye-oven kwishishini le-ceramic kunye ne-refractory.

Imiqadi enomthamo wokuthwala ubushushu obuphezulu osetyenziswa ixesha elide ngaphandle kokuguquka okugobileyo, ifanelekile ngakumbi kwii-oven tunnel, i-shuttle kiln, kwi-roller kiln enezitezi ezimbini kunye nezinye ii-oven zemizi-mveliso ezinesakhiwo se-bearing. Iiklabhu zisebenza kwi-ceramics ezisetyenzisiweyo zemihla ngemihla, i-porcelain yococeko, i-building Ceramic, izinto ze-Magnetic kunye nendawo yokutshisa ubushushu obuphezulu kwi-oven roller.

| INTO | I-RBSIC (SISIC) | I-SSIC | |

|---|---|---|---|

| IYUNITHI | IDATHA | IDATHA | |

| UBUSHUSHU OBUPHEZULU BESISEKO | C | 1380 | 1600 |

| UXINANO | g/cm3 | >3.02 | >3.1 |

| I-POROSITY EVULEKILEYO | % | <0.1 | <0.1 |

| AMANDLA OKUGOBA | I-Mpa | 250(20c) | >400 |

| I-MPa | 280 (1200 C) | ||

| I-MODULUS YOKUQHUBEKA | I-Gpa | 330 (20c) | 420 |

| I-GPa | 300 (1200c) | ||

| UKUQHUBA KWE-THERMAL | W/mk | 45 (1200 c) | 74 |

| I-COEFFICIENT YOKWANDISWA KWE-THERMAL | K x 10 | 4.5 | 4.1 |

| Ubunzima beVickers HV | I-Gpa | 20 | 22 |

| I-asidi ye-alkaline – uProff |

Iimpawu:

*Ukumelana nokukrala okuphezulu

*Ukusebenza kakuhle kwamandla

*Akukho deformation phantsi kobushushu obuphezulu

*Ubushushu obuphezulu obunyamezelayo yi-1380-1650 degrees celsius

*Ukumelana nokugqwala

* Amandla aphezulu okugoba phantsi kwe-1100 degree: 100-120MPA

I-Shandong Zhongpeng Special Ceramics Co., Ltd yenye yezona zisombululo zinkulu zezinto ezintsha ze-silicon carbide ceramic eTshayina. I-SiC technical ceramic: Ubunzima bukaMoh buyi-9 (Ubunzima bukaMoh obuyi-13), bunokumelana okuhle nokukhukuliseka kunye nokugqwala, ukukrala okugqwesileyo - ukumelana nokubola kunye nokuchasana ne-oxidation. Ubomi benkonzo yemveliso yeSiC bubude obuphindwe ka-4 ukuya ku-5 kune-92% ye-alumina material. I-MOR ye-RBSiC iphindwe ka-5 ukuya ku-7 kune-SNBSC, ingasetyenziselwa iimilo ezinzima ngakumbi. Inkqubo yokucaphula iyakhawuleza, ukuhanjiswa kunjengoko kuthembisiwe kwaye umgangatho awulingani. Sihlala siqhubeka nokuchasa iinjongo zethu kwaye sibuyisela iintliziyo zethu kuluntu.