I-Silicon yesinyithi ecocekileyo kakhulu eyi-99% ye-ingot yesinyithi

I-silicon briquette/umgubo

I-Silicon Metal icutshungulwa yi-silicon egqwesileyo yemizi-mveliso kwaye iquka iintlobo ezipheleleyo. Isetyenziswa kwishishini le-electro, i-metallurgy kunye neekhemikhali. Yi-powder yesilivere engwevu okanye engwevu emnyama ene-metallic luster, ene-melting point ephezulu, ukumelana nobushushu okuhle, ukumelana okuphezulu kunye nokumelana ne-oxidation ephezulu, ibizwa ngokuba yi-"industrial glutamate", eyimveliso ebalulekileyo esisiseko kwishishini le-hi-tech.

1. Isetyenziswa kakhulu kwizixhobo ezichasayo kunye noshishino lwesinyithi esinamandla ukuphucula ukumelana nobushushu, ukumelana nokuguguleka kunye nokumelana ne-oxidation.

2. Kumgca weekhemikhali we-organic silicon, umgubo we-industrial silicon yimpahla esisiseko ekumgangatho ophezulu kune-polymer ephezulu ye-organic silicon formatting.

3. Umgubo we-silicon yemizi-mveliso ufakwa kwi-silicon e-monocrystalline, esetyenziswa kakhulu kwicandelo le-highttech njengezinto ezibalulekileyo zokwenziwa kwesekethe edibeneyo kunye ne-element ye-elektroniki.

4. Kwi-metallurgy nakwi-foundry line, umgubo we-silicon wezimboni uthathwa njengowongezelelo lwe-iron base alloy, i-alloy ye-pharmaceutical ye-silicon steel, ngaloo ndlela iphucula ukuqina kwentsimbi.

Inkcazo (Ukwakheka kweekhemikhali)

| Igadi | Ukwakhiwa | ||||

| Umxholo(%) | Ukungcola(%) | ||||

| Fe | Al | Ca | P | ||

| 1501 | 99.69 | 0.15 | 0.15 | 0.01 | ≤0.004% |

| 1502 | 99.68 | 0.15 | 0.15 | 0.02 | ≤0.004% |

| 1101 | 99.79 | 0.1 | 0.1 | 0.01 | ≤0.004% |

| 2202 | 99.58 | 0.2 | 0.2 | 0.02 | ≤0.004% |

| 2502 | 99.48 | 0.25 | 0.25 | 0.02 | ≤0.004% |

| 3303 | 99.37 | 0.3 | 0.3 | 0.03 | ≤0.005% |

| 411 | 99.4 | 0.4 | 0.1 | 0.1 | ≤0.005% |

| 421 | 99.3 | 0.4 | 0.2 | 0.1 | - |

| 441 | 99.1 | 0.4 | 0.4 | 0.1 | - |

| 551 | 98.9 | 0.5 | 0.5 | 0.1 | - |

| 553 | 98.7 | 0.5 | 0.5 | 0.3 | - |

Ubungakanani: 10-50 mm okanye ngokweemfuno zomthengi

Ukupakisha: 1mt/ibhegi enkulu okanye ngokweemfuno zomthengi

Phawula: iinkcukacha kunye nobukhulu zinokwenziwa ngcono ngokweemfuno zomthengi ngamnye.

Ukupakishwa kunye nokuthunyelwa

1. Iphakheji: Ukupakisha okufanelekileyo ulwandle, kuthunyelwa ngesikhongozeli okanye ngobuninzi Ukuncipha kweplastiki (okungenakukhuselwa) + Ikheyiji (eyakhiwe ngentsimbi) + Ipalethi, zonke zilungelelaniswa neemfuno ezithile zomthengi.

2. Ukuthunyelwa ngaphakathi kweentsuku ezi-3 zokusebenza emva kwemveliso. (ukuthunyelwa eKorea naseJapan malunga neentsuku ezimbini; ukuthunyelwa eYurophu malunga neentsuku ezingama-40.

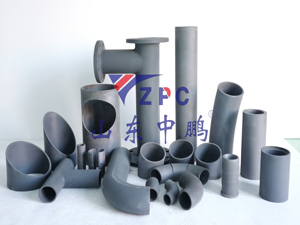

I-Shandong Zhongpeng Special Ceramics Co., Ltd yenye yezona zisombululo zinkulu zezinto ezintsha ze-silicon carbide ceramic eTshayina. I-SiC technical ceramic: Ubunzima bukaMoh buyi-9 (Ubunzima bukaMoh obuyi-13), bunokumelana okuhle nokukhukuliseka kunye nokugqwala, ukukrala okugqwesileyo - ukumelana nokubola kunye nokuchasana ne-oxidation. Ubomi benkonzo yemveliso yeSiC bubude obuphindwe ka-4 ukuya ku-5 kune-92% ye-alumina material. I-MOR ye-RBSiC iphindwe ka-5 ukuya ku-7 kune-SNBSC, ingasetyenziselwa iimilo ezinzima ngakumbi. Inkqubo yokucaphula iyakhawuleza, ukuhanjiswa kunjengoko kuthembisiwe kwaye umgangatho awulingani. Sihlala siqhubeka nokuchasa iinjongo zethu kwaye sibuyisela iintliziyo zethu kuluntu.