I-Silicon yensimbi engu-99% yokuhlanzeka okuphezulu

I-Silicon briquette/impuphu

I-Silicon Metal icutshungulwa yi-silicon yezimboni enhle kakhulu futhi ifaka izinhlobo ezigcwele. Isetshenziswa embonini ye-electro, metallurgy kanye namakhemikhali. Ingumpuphu wesiliva ompunga noma ompunga omnyama one-metallic luster, enezinga eliphezulu lokuncibilika, ukumelana okuhle nokushisa, ukumelana okuphezulu kanye nokumelana okuphezulu kwe-oxidation, ibizwa ngokuthi “i-glutamate yezimboni”, okuyizinto eziyisisekelo eziyisisekelo zokusetshenziswa embonini yezobuchwepheshe obuphezulu.

1. Isetshenziswa kabanzi embonini yezinto eziphikisayo kanye ne-metallurgy yamandla ukuthuthukisa ukumelana nokushisa, ukumelana nokuguguleka kanye nokumelana ne-oxidation.

2. Emgqeni wamakhemikhali we-silicon ephilayo, i-silicon powder yezimboni iyizinto eziyisisekelo zokusetshenziswa eziqukethe i-polymer ephezulu yokufometha kwe-silicon ephilayo.

3. Impuphu ye-silicon yezimboni ifakwa ngaphansi kwe-silicon e-monocrystalline, esetshenziswa kabanzi emkhakheni we-highttech njengento ebalulekile yokusetshenziswa kwesekethe ehlanganisiwe kanye ne-elekthronikhi.

4. Emugqeni we-metallurgy kanye ne-foundry, i-industrial silicon powder ibhekwa njengesengezo se-iron base alloy, i-alloy steel ye-silicon, ngaleyo ndlela ithuthukise ukuqina kwensimbi.

Ukucaciswa (Ukwakheka kwamakhemikhali)

| I-Garde | Ukwakheka | ||||

| Okuqukethwe kwe-Si(%) | Ukungcola(%) | ||||

| Fe | Al | Ca | P | ||

| 1501 | 99.69 | 0.15 | 0.15 | 0.01 | ≤0.004% |

| 1502 | 99.68 | 0.15 | 0.15 | 0.02 | ≤0.004% |

| 1101 | 99.79 | 0.1 | 0.1 | 0.01 | ≤0.004% |

| 2202 | 99.58 | 0.2 | 0.2 | 0.02 | ≤0.004% |

| 2502 | 99.48 | 0.25 | 0.25 | 0.02 | ≤0.004% |

| 3303 | 99.37 | 0.3 | 0.3 | 0.03 | ≤0.005% |

| 411 | 99.4 | 0.4 | 0.1 | 0.1 | ≤0.005% |

| 421 | 99.3 | 0.4 | 0.2 | 0.1 | - |

| 441 | 99.1 | 0.4 | 0.4 | 0.1 | - |

| 551 | 98.9 | 0.5 | 0.5 | 0.1 | - |

| 553 | 98.7 | 0.5 | 0.5 | 0.3 | - |

Usayizi: 10-50 mm noma ngokwesidingo sekhasimende

Ukupakisha: 1mt/isikhwama esikhulu noma ngokwesidingo sekhasimende

Phawula: imininingwane kanye nosayizi kungenziwa ngcono ngokwezidingo zamakhasimende.

Ukupakisha Nokuthumela

1. Iphakheji: Ukupakisha okufanele ulwandle, okuthunyelwa ngesitsha noma ngobuningi Ukuncishiswa kwepulasitiki (okungavimbeli) + Ikheji (elakhiwe ngensimbi) + Iphalethi, konke kulungiseka ngokwezidingo ezithile zamakhasimende.

2. Ukuthunyelwa kungakapheli izinsuku ezintathu zokusebenza ngemuva kokukhiqizwa. (kuthunyelwa eKorea naseJapane cishe izinsuku ezimbili; kuthunyelwa eYurophu cishe izinsuku ezingu-40.

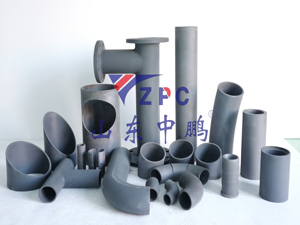

I-Shandong Zhongpeng Special Ceramics Co., Ltd ingenye yezixazululo ezinkulu zezinto ezintsha ze-silicon carbide ceramic eShayina. I-SiC technical ceramic: Ubulukhuni bukaMoh buyi-9 (ubulukhuni bukaMoh obuyi-13), bunokumelana okuhle kakhulu nokuguguleka nokugqwala, ukumelana okuhle kakhulu - ukumelana nokugqwala kanye nokulwa nokubola. Impilo yesevisi yomkhiqizo we-SiC ide ngokuphindwe ka-4 kuya ku-5 kune-92% ye-alumina material. I-MOR ye-RBSiC iphindwe ka-5 kuya ku-7 kune-SNBSC, ingasetshenziswa ezimweni eziyinkimbinkimbi kakhulu. Inqubo yokucaphuna iyashesha, ukulethwa kunjengoba kuthenjisiwe futhi ikhwalithi ayilingani. Sihlala siphikelela ekuphonseni inselelo imigomo yethu futhi sibuyisela izinhliziyo zethu emphakathini.