Libalaka tsa silicon carbide

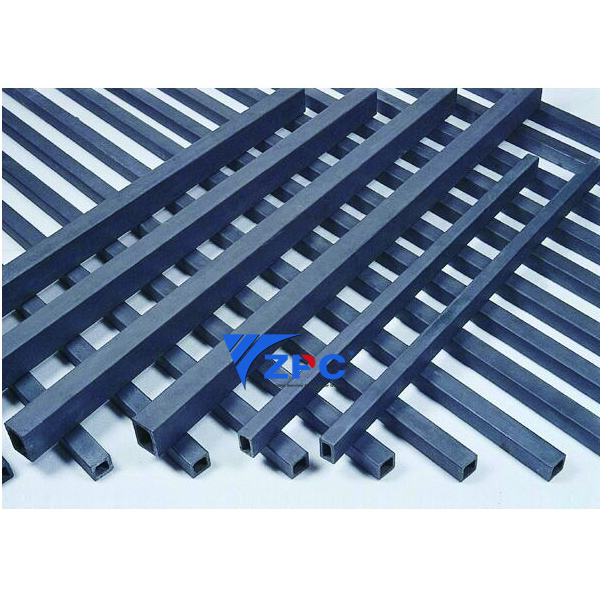

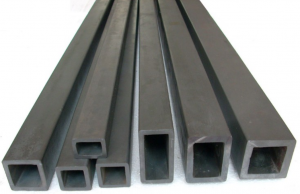

Karabelo e Kopantsoeng ea Silicon Carbide Matla a Phahameng a Phahameng a Otlolohileng a Sisic/Rbsic Rollers le Libalaka

Roller ea silicon carbide ea ceramics e sebelisoang haholo-holo bakeng sa indasteri ea betri ea lithium, porcelain ea letsatsi le letsatsi, porcelain ea bohloeki, li-ceramics tsa kaho le thepa ea makenete, joalo ka roller oven, ho chesa mocheso o phahameng ka oven e loketseng, ka bophelo bo bolelele ba ts'ebeletso. E na le matla a mocheso o phahameng, ho hanyetsa mocheso, ho hanyetsa ho hasana ha mocheso o phahameng, ho hanyetsa ho hoholo ha mocheso, ho hanyetsa ho matla, ho hanyetsa ho tsofala hantle. Li-rollers tse nang le bokhoni ba ho jara mocheso o phahameng ba tšebeliso e kholo, ea nako e telele ntle le ho kobeha, haholo-holo li loketse li-kiln tsa tunnel, shuttle oven, ka oven ea roller e nang le mekhahlelo e 'meli le sebopeho se seng sa foreimi ea ho jara mojaro oa oven ea indasteri.

Lihlopha li sebelisoa letsatsi le letsatsi - li-ceramic tse sebelisitsoeng, porcelain ea bohloeki, Ceramic ea Moaho, thepa ea makenete le sebaka sa ho besa se nang le mocheso o phahameng sa onto ea roller.

| Silicon Carbide Tlhaloso ea Sehlahisoa: | ||||

| Ntho | Yuniti | SSIC | RBSIC SISIC | R-SIC |

| Bohloeki | (%) | ≥ 99 | ≥90% | ≥ 99 |

| Mocheso oa kopo | ºC | 1700 | 1380 | 1650 |

| Botenya | g/CM2 | ≥3.10-3.15 | ≥3.02 | 2.65-2.75 |

| Maro a bulehileng | % | ≤0.1 | ≤0.1 | |

| Bothata | ≥92 HRA | 2400 Kg/mm2 | 1800-2000 Kg/mm2 | |

| Matla a ho kobeha | MPa | 400-580 | 250(20ºC) | ≥300 |

| 281 (1200ºC) | ||||

| Matla a tšepe | Mpa | ≥200 | ≥190 | |

| modulus ea elasticity | GPa | 400 | 332(20ºC) | 80-100 (20ºC) |

| 300 (1200ºC) | 90-110 (1200ºC) | |||

| Ho khanna ha mocheso | W/mk | 100-120 | 45 (1200ºC) | 36 |

| Tekanyo e sebetsang ea katoloso ea mocheso | K1X 106 | 4.2 | 4.5 | 4.6 |

| Ho tiea | Gpa | >25 | 13 | |

| Khanyetso ea asiti le Ikali | E babatsehang | E babatsehang | E babatsehang | |

| Tlhaloso ea Sehlahisoa sa SiC: | ||||

| Ntho | Yuniti | OC-1 | OC-2 | MC-3 |

| SiC | (%) | ≥90 | ≥86 | ≥80 |

| Ho bonahala eka ho na le masoba | (%) | ≤10 | ≤13 | ≤16 |

| Botenya | g/CM2 | ≥2.66 | ≥2.63 | ≥2.6 |

| Mocheso oa kopo | ºC | ≥1680 | ≥1620 | ≥1550 |

| Tekanyo e sebetsang ea katoloso ea mocheso | aX 10-6/ºC | ≤4.8 | ≤5.0 | ≤5.5 |

| Matla a ho Koba | 1200ºC | ≥45 | ≥40 | ≥30 |

Shandong Zhongpeng Special Ceramics Co., Ltd ke e 'ngoe ea litharollo tse kholo ka ho fetisisa tsa thepa e ncha ea silicon carbide Chaena. SiC technical ceramic: Bothata ba Moh ke 9 (Bothata ba Moh bo bocha ke 13), bo nang le khanyetso e ntle khahlanong le khoholeho le mafome, khanyetso e ntle - khanyetso le anti-oxidation. Bophelo ba tšebeletso ea sehlahisoa sa SiC bo bolelele ka makhetlo a 4 ho isa ho a 5 ho feta thepa ea alumina ea 92%. MOR ea RBSiC e feta ka makhetlo a 5 ho isa ho a 7 ho feta SNBSC, e ka sebelisoa bakeng sa libopeho tse rarahaneng haholoanyane. Ts'ebetso ea khotheishene e potlakile, phano e etsoa joalo ka ha e tšepisitsoe 'me boleng ha bo fete letho. Kamehla re phehella ho phephetsa lipheo tsa rona 'me re khutlisetsa lipelo tsa rona sechabeng.