Matanda esilicon carbide

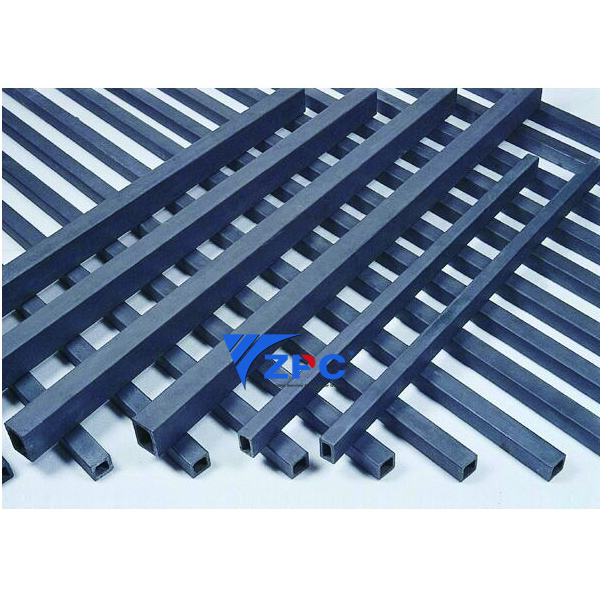

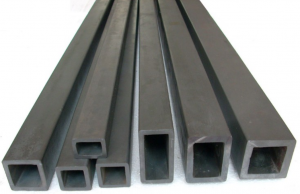

Reaction Bonded Silicon Carbide High Strength High Straightness Sisic/ Rbsic Rollers and Beams

Roller yesimbi yesilicon carbide ceramics inogadzirwa ne "reaction sintering" inonyanya kushandiswa muindasitiri yebhatiri re lithium, porcelain yezuva nezuva, porcelain yehutsanana, ceramics dzekuvaka nezvinhu zvemagineti, zvakaita se "roller kiln", "high tembiricha" inopiswa ne "kiln" yakanaka, ine hupenyu hurefu hwebasa. Ine simba rekupisa kwakanyanya, "thermal shock resistance", "high tembiricha" inodzivirira kukwira kwemvura, "strong resistance", "strong resistance", "good wear resistance". Ma "roller" ane "high tembiricha bearing" anogona kushandiswa kwenguva refu pasina "kukombama deformation", akakodzera ma "tunnel kiln", "shuttle kiln", "two-layer roller kiln" uye mamwe maindasitiri "industrial furnace load" - chimiro che "bearing load".

Makirabhu anoshandiswa zuva nezuva - maceramic akamboshandiswa, porcelain yekuchenesa, Ceramic yekuvaka, Magnetic material uye nzvimbo yekupisira moto ye roller kiln inodziya zvakanyanya.

| Silicon Carbide Chigadzirwa Chinotsanangurwa: | ||||

| Chinhu | Chikamu | SSIC | RBSIC SISIC | R-SIC |

| Kuchena | ( %) | ≥ 99 | ≥90% | ≥ 99 |

| Tembiricha yekushandisa | ºC | 1700 | 1380 | 1650 |

| Kuwanda kwevanhu | g/CM2 | ≥3.10-3.15 | ≥3.02 | 2.65-2.75 |

| Maburi akavhurika | % | ≤0.1 | ≤0.1 | |

| Kuoma | ≥92 HRA | 2400 Kg/mm2 | 1800-2000 Kg/mm2 | |

| Simba rekukotama | MPa | 400-580 | 250(20ºC) | ≥300 |

| 281 (1200ºC) | ||||

| Simba rekusimba | Mpa | ≥200 | ≥190 | |

| modulus yekusimba | GPa | 400 | 332(20ºC) | 80-100 (20ºC) |

| 300 (1200ºC) | 90-110 (1200ºC) | |||

| Kufambisa kwekupisa | W/mk | 100-120 | 45 (1200ºC) | 36 |

| Kuwanda kwekuwedzera kwekupisa | K1X 106 | 4.2 | 4.5 | 4.6 |

| Kuomarara | Gpa | >25 | 13 | |

| Kudzivirira kweAcid & Ikali | Zvakanakisa | Zvakanakisa | Zvakanakisa | |

| Tsanangudzo yeSiC Chigadzirwa: | ||||

| Chinhu | Chikamu | OC-1 | OC-2 | MC-3 |

| SiC | (%) | ≥90 | ≥86 | ≥80 |

| Kuonekwa Kunoyerera | (%) | ≤10 | ≤13 | ≤16 |

| Kuwanda kwevanhu | g/CM2 | ≥2.66 | ≥2.63 | ≥2.6 |

| Tembiricha yekushandisa | ºC | ≥1680 | ≥1620 | ≥1550 |

| Kuwanda kwekuwedzera kwekupisa | aX 10-6/ºC | ≤4.8 | ≤5.0 | ≤5.5 |

| Simba Rekukombama | 1200ºC | ≥45 | ≥40 | ≥30 |

Shandong Zhongpeng Special Ceramics Co., Ltd ndeimwe yemhando huru dzesilicon carbide ceramic itsva muChina. SiC technical ceramic: Kuomarara kwaMoh kwa9 (Kuomarara kwaNew Moh kwa13), nekusimba kwakanaka pakukukurwa nekuora, kusimba kwakanaka - kusimba uye kudzivirira oxidation. Hupenyu hwebasa rechigadzirwa cheSiC hwakareba ka4 kusvika ka5 kupfuura 92% alumina material. MOR yeRBSiC yakapetwa ka5 kusvika ka7 kupfuura SNBSC, inogona kushandiswa kune mamwe maumbirwo akaomarara. Maitiro ekukosha kwemashoko anokurumidza, kuendesa kwacho kwakaitwa sezvakavimbiswa uye mhando yacho haina kukosha. Tinogara tichiramba tichipikisa zvinangwa zvedu uye tinopa moyo yedu kunharaunda.