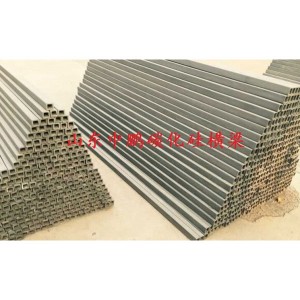

Silicon carbide cantilever manufacturer

Silicon carbide cantilever propeller is widely used in semiconductor industry.

Silicon carbide cantilever with high – temperature bearing capacity of large, long-term use without bending deformation, especially suitable for tunnel kilns, shuttle kiln, in two – layer roller kiln and other industrial furnace load – bearing structure of frame.

RBSiC (SiSiC) cantilever Technical Parameter:

| item | unit | data |

| temperature of application | C | 1380 |

| density | g/cm3 | >=3.02 |

| open porosity | % | <0.1 |

| bending strength | Mpa | 250(20C) |

| Mpa | 280(1200C) | |

| modulus of elasticity | Gpa | 330(20C) |

| Gpa | 300(1200C) | |

| thermal conductivity | W/m.k | 45(1200C) |

| coefficient of thermal expansion | K-1*10-6 | 4.5 |

| rigidity | 13 | |

| acid-proof alkaline | Excellent

|

The Reaction Bonded Silicon Carbide Ceramic (RSIC/SISIC) is an ideal wear resistant material, which is especially suitable for the strong abrasive, coarse particles, classification, concentration, dehydration and the other operations. It is widely used in mining industry, steel industry, coal processing industry, chemical industry, raw material-making industry, mechanical sealing, surface sandblasted treatment and reflector etc. Thanks to the excellent hardness and abrasive resistance, it can effectively protect the part where need wear protection, so as to prolong the service life of the equipment.

Thickness: from 6mm up to 25mm

Regular Shape: SISIC plate, SISIC Pipe, SiSiC Three Links, SISIC Elbow, SISIC Cone Cyclone. Remark: Other sizes and shape are available upon requests.

In carton box, packed in fumigated wooden pallet with net weight 20-24MT/20′FCL.

Shandong Zhongpeng Special Ceramics Co., Ltd is one of the largest silicon carbide ceramic new material solutions in China. SiC technical ceramic: Moh’s hardness is 9 (New Moh’s hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. SiC product’s service life is 4 to 5 times longer than 92% alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. The quotation process is quick, the delivery is as promised and the quality is second to none. We always persist in challenging our goals and give our hearts back to society.