In the industrial production process, desulfurization is a crucial environmental protection measure, especially in industries such as electricity and steel. Burning fossil fuels such as coal will produce a large amount of exhaust gas containing sulfur dioxide. If directly discharged, it will cause serious pollution to the atmospheric environment and lead to environmental problems such as acid rain. And the silicon carbide desulfurization nozzle, like a silent guardian of the environment, plays an irreplaceable key role in the field of industrial desulfurization.

What is a silicon carbide desulfurization nozzle

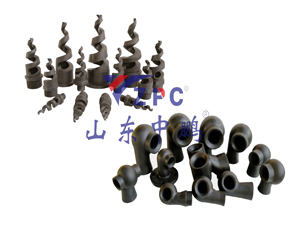

The name of the silicon carbide desulfurization nozzle indicates that its main material is silicon carbide, which is a new type of ceramic material with excellent performance. It is not an ordinary nozzle, but specifically designed for industrial desulfurization scenarios. It is mainly used to evenly spray desulfurizing agents (such as common limestone slurry) onto flue gas containing pollutants such as sulfur dioxide, allowing the desulfurizer to fully contact and undergo chemical reactions with the flue gas, thereby removing harmful gases such as sulfur dioxide from the flue gas and achieving flue gas purification.

Advantages of silicon carbide desulfurization nozzle

1. Super high temperature resistance: In many industrial production scenarios, such as power plant boilers, the exhaust gas temperature is quite high. The silicon carbide desulfurization nozzle can easily cope with it. It can work stably in high temperature environments and can generally withstand high temperatures without deformation or damage due to high temperatures. This ensures that it can always play a normal role in spraying desulfurizer during the high-temperature flue gas desulfurization process.

2. Excellent wear resistance: During the desulfurization process, the nozzle will continue to be washed away by high-speed flowing desulfurizers (such as limestone slurry, a liquid with certain particles). Ordinary material nozzles may be quickly worn out, but silicon carbide desulfurization nozzles have high hardness and strong wear resistance, which can resist this erosion and wear for a long time, greatly extending their service life and reducing the trouble and cost of frequent nozzle replacement.

3. Strong corrosion resistance: There are various corrosive media such as acids, alkalis, and salts in the desulfurization environment, and silicon carbide has good resistance to these corrosive media. Even if exposed to such harsh chemical environments for a long time, it is not easily corroded or damaged, and its performance remains stable.

4. Good atomization effect: In order to improve desulfurization efficiency, it is necessary to fully contact the desulfurizer with the flue gas. The silicon carbide desulfurization nozzle can evenly spray the desulfurizer into small droplets, making the droplet size distribution uniform. This increases the contact area between the desulfurizer and the flue gas, which is conducive to a more complete desulfurization reaction.

5. Excellent thermal shock resistance: In industrial production, the temperature of the desulfurization system may change rapidly, such as during equipment start-up and shutdown. Silicon carbide desulfurization nozzles have good thermal shock resistance and can withstand rapid temperature changes without cracking or damage, adapting to temperature fluctuations in desulfurization systems.

Application fields of silicon carbide desulfurization nozzles

Silicon carbide desulfurization nozzles are widely used in various industrial fields with high environmental requirements:

Power industry: Power plants are one of its main application places. In the desulfurization tower of a coal-fired power plant, the silicon carbide desulfurization nozzle is an important component of the spray layer, responsible for evenly spraying the desulfurizer into the flue gas, effectively removing sulfur dioxide from the flue gas, and helping the power plant meet emission standards.

Steel industry: In the sintering machine flue gas desulfurization system of steel plants, it also plays a key role in reducing the sulfur content in the exhaust gas emitted during the steel production process and minimizing air pollution.

Although small in size, silicon carbide desulfurization nozzles play a crucial role in industrial desulfurization and environmental protection due to their excellent performance. With increasingly strict environmental requirements, we believe that silicon carbide desulfurization nozzles will play a role in more industrial scenarios, safeguarding bluer skies and fresher air for us.

Post time: Aug-11-2025