amathayili epayipi le-ceramic amelana nokuguguleka - amathayili e-silicon carbide namathayili e-alumina

I-silicon carbide eboshiwe yi-reaction (i-SiSiC noma i-RBSIC) iyinto efanelekile yokumelana nokuguguleka, okuyi-

ifaneleka kakhulu ekuguguleni okunamandla, izinhlayiya eziqinile, ukuhlukaniswa, ukuhlushwa, ukuphelelwa amanzi emzimbeni kanye

eminye imisebenzi. Isetshenziswa kabanzi embonini yezimayini, embonini yensimbi, embonini yokucubungula amakhorali, nakweminye imisebenzi yamakhemikhali

imboni, imboni yokwenza izinto zokusetshenziswa, ukuvalwa kwemishini, ukwelashwa okufakwe isihlabathi kanye ne-reflector njll.

Ngenxa yobulukhuni obuhle kakhulu kanye nokumelana nokuklwebheka, ingavikela ngempumelelo ingxenye lapho kudingeka khona ukugqokwa

ukuvikelwa, ukuze kwandiswe isikhathi senkonzo yemishini.

Isikhathi senkonzo ye-SiC ceramics side kakhulu kunese-92% ye-alumina ceramics.

Ungawabona kanjani futhi uthole amapuleti, amathayili, ama-liners asezingeni eliphezulu amelana nokuguguleka kwe-silicon carbide?

Amathayili, ama-liners, namapayipi angagugi e-silicon carbide asetshenziswa kabanzi embonini yezimayini.

Amaphuzu alandelayo angasetshenziswa ukubhekisela kuwo:

1. Ifomula kanye nenqubo:

Kunezinhlobo eziningi ze-SiC emakethe. Sisebenzisa izinhlobo zangempela zaseJalimane. Ezivivinyweni zelebhu eziphezulu, ukulahlekelwa kwethu yi-"Erosion ㎝³" yomkhiqizo kungafinyelela ku-0.85 ± 0.01;

2. Ubulukhuni:

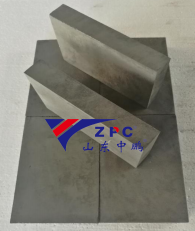

Amathayili e-SiC akhiqizwa nge-ZPC: ubulukhuni obusha be-Mohs: 14.55 ± 4.5 (MOR, psi)

3. Ubuningi:

Ububanzi bobuningi bethayela le-ZPC SiC bungaba ngu-3.03+0.05.

4. Osayizi kanye Nomphezulu:

Amathayili e-SiC akhiqizwa ku-ZPC ngaphandle kwemifantu kanye nezikhala, anezindawo eziyisicaba kanye nemiphetho namakhona aphelele.

5. Izinto zangaphakathi:

Ama-liners/amathayela amelana nokuguguleka e-silicon carbide anezinto zangaphakathi nezangaphandle ezincane nezifanayo.

If any questions, please feel free to contact us: info@rbsic-sisic.com

■Imininingwane:

| Into | Iyunithi | Idatha |

| Izinga lokushisa lokusetshenziswa | ℃ | 1380℃ |

| Ubuningi | G/cm3 | >3.02 |

| Imbobo evulekile | % | <0.1 |

| Amandla okugoba -A | I-Mpa | 250 (20℃) |

| Amandla okugoba -B | I-MPa | 280 (1200℃) |

| I-Modulus yokunwebeka-A | I-GPa | 330(20℃) |

| I-Modulus yokunwebeka -B | I-GPa | 300 (1200℃) |

| Ukuqhuba kwe-thermal | I-W/mk | 45 (1200℃) |

| Isilinganiso sokunwetshwa kokushisa | K-1 ×10-6 | 4.5 |

| Ukuqina | / | 13 |

| I-alkaline engangenisi i-asidi | / | kuhle kakhulu |

■Ukuma nosayizi okutholakalayo:

Ubukhulu: kusuka ku-6mm kuya ku-25mm

Isimo Esijwayelekile: Ipuleti le-SISIC, Ipayipi le-SISIC, Izixhumanisi Ezintathu ze-SiSiC, I-SISIC Elbow, Isishingishane Sekhoni le-SISIC.

Isaziso: Amanye amasayizi nesimo kuyatholakala uma ucela.

■Ukupakisha:

Ebhokisini lebhokisi, lipakishwe epalethini lokhuni elifuthwe nge-fumigation elinesisindo esingu-20-24MT/20′FCL.

■Izinzuzo ezibalulekile:

1. Ukumelana okuhle kakhulu nokuguguleka, ukumelana nokushayisana kanye nokumelana nokugqwala;

2. Ukuthamba okuhle kakhulu nokumelana nokushisa okuhle kakhulu kuze kufike ku-1350℃

3. Ukufakwa okulula;

4. Impilo yesevisi ende (cishe iphindwe kasikhombisa kuneye-alumina ceramic kanye nephindwe kayishumi kuneye-

i-polyurethane

Iphethini yokuguguleka komthelela we-engeli Ukuguguleka okushelelayo okuphansi kwe-engeli

Uma ukugeleza kwezinto ezihudulayo kushaya indawo egugile nge-engeli engajulile noma kudlula eduze kwayo, uhlobo lokuguguleka okwenzeka ekungqubuzaneni lubizwa ngokuthi ukuguguleka okushelelayo.

I-silicon carbide ceramics ethuthukisiwe inikeza amathayili kanye ne-lining ye-ceramic ukumelana nokuguguleka kanye nokumelana nokugqwala. Le mikhiqizo iye yafakazelwa ukuthi iguguleka kwemishini enqubweni yokuthutha, ukucubungula, kanye nokugcina. Amathayili ethu angakhiqizwa ngobukhulu obusukela ku-8 kuya ku-45mm. Kubalulekile ukuqinisekisa ukuthi ungathola imikhiqizo edingekayo. I-SiSiC: Ubulukhuni bukaMoh bungu-9.5 (Ubulukhuni bukaNew Moh bungu-13), obunokumelana okuhle kakhulu nokuguguleka kanye nokugqwala, ukuguguleka okuhle kakhulu - ukumelana nokulwa nokugqwala. Inamandla ngokuphindwe ka-4 kuya ku-5 kune-nitride bonded silicon carbide. Impilo yesevisi ide ngokuphindwe ka-5 kuya ku-7 kune-alumina material. I-MOR ye-RBSiC iphindwe ka-5 kuya ku-7 kune-SNBSC, ingasetshenziswa ezimweni eziyinkimbinkimbi kakhulu. I-lining ye-ceramic emelana nokugqwala iyasebenza ukwenza ngcono ukusebenza kokukhiqiza, ukusebenza kahle, ukunciphisa izindleko zokulungisa kanye nokwandisa inzuzo.

I-ceramics enembile inolwazi lwezinto ezibonakalayo, ubuchwepheshe obusetshenzisiwe kanye namakhono obunjiniyela. Lokhu kungaqinisekisa ngempumelelo ukuthi amakhasimende ethu anikezwa izixazululo ezinhle kakhulu. Amathayili e-silicon carbide ceramic kanye ne-lining kuvame ukusetshenziswa ezicelweni ezifana nezishingishane, amashubhu, ama-chutes, ama-hopper, amapayipi, amabhande okuhambisa kanye nezinhlelo zokukhiqiza. Kuhlelo, kunezinto ezihambayo ezishelelayo phezu komhlaba. Lapho into ishelela phezu kwento ethile, iguga kancane kancane izingxenye kuze kube yilapho kungasali lutho. Ezindaweni eziguga kakhulu, lokhu kungenzeka njalo futhi kubangele izinkinga eziningi ezibizayo. Isakhiwo esiyinhloko sigcinwa ngokusebenzisa into eqinile kakhulu, njenge-silicon carbide ceramics kanye ne-alumina ceramics njenge-lining yokuzinikela. Ngesikhathi esifanayo, i-silicon carbide ceramics ingabekezelela ukuguga isikhathi eside ngaphambi kokuba idinga ukushintshwa, impilo yenkonzo ye-silicon carbide ceramic iphindwe kahlanu kuya kasikhombisa kune-alumina material.

Izakhiwo zeCeramic Tiles zeSilicon Carbide Ceramic Resistant Ceramic kanye neLining:

Ayimelani namakhemikhali

Ukuvikela ugesi

Ukuguguleka kwemishini kanye nokumelana nokuguguleka

Ingashintshwa

Izinzuzo zamathayela nama-Lining amelana nokugqokwa kwe-Ceramic:

Ingasetshenziswa lapho kudingeka khona ukubekezelelana okuqinile noma ulwelwesi oluncane

Ingasetshenziswa ukuphinda iveze izindawo ezigugile ezikhona

Ingasetshenziswa ngezindlela eziningi zokunamathisela njengokushisela kanye nezinamathiseli

Yenzelwe ngokwezifiso izinhlelo zokusebenza ezithile

Imelana nokugqwala kakhulu

Isixazululo sokunciphisa ukuguguleka okulula

Ivikela izingxenye ezihambayo ezisengozini yokuguga kakhulu

Ihlala isikhathi eside futhi isebenza kahle kakhulu kunezixazululo zokunciphisa ukuguguleka

Izinga lokushisa eliphezulu kakhulu lokusetshenziswa elifika ku-1380°C

1、 Isitshalo sensimbi nensimbi: 1, ulwelwesi lokuxuba imigqomo yomshini wokusila 2, irabha ye-ceramic egoqwe ngemigqomo 3, i-impeller yefeni 4, i-disc feeder, umkhombe wezinto ezomile 5, i-coke hopper, i-converter bin, i-coke bin, i-cyclone dust collector.

2、 Isitshalo sikagesi: 1. Indawo yokukhipha i-ball mill, i-volute yesigayo, indawo yokukhipha i-medium speed mill, i-powder pipe elbow, i-cyclone dust collector, i-silo, i-hopper 2, i-coal hopper, i-coarse and fine powder separator, i-coal mill outreying hopper 3, i-coal hopper of bridge grab, i-centre coal hopper ye-coal digger, i-outlet ye-ball mill, i-inlet and outlet ye-coarse and fine powder separator, i-volute ye-powder exhauster 4 Izinhlobo ezahlukene zamandla aqondile, ajikelezayo futhi ancibilikisayo amelana nokuguguleka aphezulu ama-boiler asebenzisa amalahle; amapayipi nezindololwane ze-ceramic ezihlanganisiwe ezingaguguleki kakhulu, izitsha ze-ceramic, abalandeli be-ceramic, ama-impeller e-ceramic, ama-valve e-ceramic, njll.; izingxenye ezahlukahlukene ezingaguguleki ezifana namabhola okugaya, imikhono yama-roller, ama-disc okugaya, amathayili e-disc, amasongo okugaya, amabhola e-nozzle nezinye izingxenye ezingaguguleki zama-coal mill asebenzisa i-medium speed; amapayipi, i-damper engaguguleki kanye nabalandeli bezincazelo ezahlukahlukene zezinhlelo zokususa umlotha kanye nokugawula; Amabhola Zonke izinhlobo zomshini wokugaya zinethayela (noma cha) le-bolt lining, ipuleti le-lining, ipayipi elijikelezayo, indandatho yegiya, ibhola lensimbi ye-chromium alloy ephansi, njll.; isondo lokushaya, ipuleti lokushaya, i-guard hook, i-armor, i-separator, ipayipi legesi le-flue lesithando lokushisa eliphezulu, njll. lomshini wokugaya amalahle wefeni; izesekeli ezidingekayo zezinhlobo ezahlukene zemishini yokuchoboza.

3, umshini wokugaya iphepha: 1. Ipayipi lamalahle elicoliwe

Imikhiqizo nezinsizakalo eziyinhloko: 1. Amapayipi e-ceramic amelana nokuguguleka kwezimboni: zonke izinhlobo ze-ceramic emelana nokuguguleka kanye nezinga lokushisa eliphezulu ehlanganiswe namalahle aphuciwe, izinsalela, i-slag slurry, ipayipi lokuthuthwa kwe-slurry, indololwane, i-elbow, i-pulverized coal burner, i-outlet ye-coal mill, i-coarse ne-fine cyclone separator, i-chute, i-hopper, i-storage bin, i-ore dressing barrel ye-mine magnetic separator; 2. I-ceramic fan emelana nokuguguleka: zonke izinhlobo ze-impeller yefeni emelana nokushisa okuphezulu, engaguguleki, engaguguleki, engaguguleki kanye ne-volute, kufaka phakathi i-centrifugal fan, i-axial flow fan, i-static blade, i-movable blade adjustable fan impeller, i-suction fan, i-powder exhaust, i-sintering fan, i-powder separation fan, i-dust removal fan, i-kiln head kanye ne-kiln tail fan, njll; 3. I-Gqoka i-ceramic lining pump kanye ne-valve: i-ceramic lining, i-pump impeller, i-shell, i-baffle, i-pipe elbow, i-pneumatic ash removal kanye ne-gas transmission valve kanye nezesekeli ze-slurry ehlukahlukene, i-slag slurry, i-mortar, i-tailings nezinye izinhlelo zokuhamba. 4. Izembozo ze-ceramic ezingagugi: zonke izinhlobo zezembozo ze-ceramic ezingagugi nezimelana nokushisa okuphezulu kanye ne-mastic zisetshenziselwa i-fan volute, ipayipi le-elbow, i-mill outlet, ipayipi lokuhlukanisa eliqinile nelincane, i-chute, i-hopper kanye ne-valve. 5. Imishini yokuhlukanisa i-magnetic engagugi: izingxenye zokuhamba kwemishini ehlukahlukene yokucubungula amaminerali eyomile nemanzi, kufaka phakathi i-magnetic separator drum, i-bottom groove, i-chute, ipayipi, amaphampu odaka ahlukahlukene, i-slurry pump volute, impeller, kanye nepayipi lokudlulisa. 6. Ubuchwepheshe bokufafaza obuphezulu: kusetshenziswa ugesi wakamuva we-inverter international pulse arc kanye nesibhamu sokufafaza se-arc esinejubane eliphezulu, izinto zensimbi ezahlukahlukene ezingagugi nezimelana nokugqwala ziyafuthwa ebusweni be-substrate yensimbi ukuze kwakheke ungqimba oluvikelayo olungagugi nokugqwala. Ingahlinzeka ngokuvikelwa okusebenzayo kuzo zonke izinhlobo zokugqwala okumaphakathi okumaphakathi.

I-Shandong Zhongpeng ZPC ceramics yibhizinisi eligxile ekukhiqizweni kwezitsha zobumba zezimboni, eligxile kakhulu ku-R&D kanye nokukhiqizwa kwezitsha zobumba ze-silicon carbide. Singakwazi ukucubungula imikhiqizo yobumba ngokwemidwebo yakho, sigxile ekukhiqizweni kosayizi omkhulu, induku yobumba enembile kakhulu, ipayipi lobumba, indandatho yobumba, ipuleti lobumba, i-flange yobumba, i-nozzle yobumba, kanye nezingxenye ezivikelwe usayizi omkhulu.

I-Shandong Zhongpeng Special Ceramics Co., Ltd ingenye yezixazululo ezinkulu zezinto ezintsha ze-silicon carbide ceramic eShayina. I-SiC technical ceramic: Ubulukhuni bukaMoh buyi-9 (ubulukhuni bukaMoh obuyi-13), bunokumelana okuhle kakhulu nokuguguleka nokugqwala, ukumelana okuhle kakhulu - ukumelana nokugqwala kanye nokulwa nokubola. Impilo yesevisi yomkhiqizo we-SiC ide ngokuphindwe ka-4 kuya ku-5 kune-92% ye-alumina material. I-MOR ye-RBSiC iphindwe ka-5 kuya ku-7 kune-SNBSC, ingasetshenziswa ezimweni eziyinkimbinkimbi kakhulu. Inqubo yokucaphuna iyashesha, ukulethwa kunjengoba kuthenjisiwe futhi ikhwalithi ayilingani. Sihlala siphikelela ekuphonseni inselelo imigomo yethu futhi sibuyisela izinhliziyo zethu emphakathini.