iithayile zeseramikhi ezingagugiyo, ii-liners

![]()

I-Reaction bonded silicon carbide (i-SiSiC okanye i-RBSIC) yinto efanelekileyo yokumelana nokuguguleka, nto leyo

ifanelekile ngokukodwa kwi-abrasive enamandla, amasuntswana arhabaxa, ukuhlelwa, uxinaniso, ukuphelelwa ngamanzi emzimbeni kunye

eminye imisebenzi. Isetyenziswa kakhulu kushishino lwemigodi, kushishino lwentsimbi, kushishino lokucubungula iikorale, kwiikhemikhali

ishishini, ishishini lokwenza izinto zokwenza izinto eziluhlaza, ukutywinwa koomatshini, unyango olugqunywe ngesanti kunye nesixhobo sokubonisa njl.njl.

Ngenxa yobunzima obugqwesileyo kunye nokumelana nokurhawuzelela, inokukhusela ngokufanelekileyo indawo apho kufuneka igugiswe khona

ukhuseleko, ukuze kwandiswe ubomi benkonzo yezixhobo.

Ungazibona njani kwaye ufumane iipleyiti, iithayile, ii-liners ezinganyangekiyo ze-silicon carbide ezisemgangathweni ophezulu?

Iithayile, ii-liners, iipayipi ezingagugiyo ze-silicon carbide ziya zisetyenziswa kakhulu kwishishini lezemigodi.

Ezi ngongoma zilandelayo zezo umele uzibhekisele kuzo:

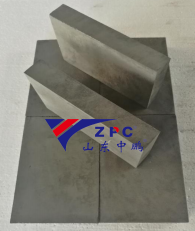

1. Ifomula kunye nenkqubo:

Kukho iintlobo ezininzi zeSiC ezithengiswayo. Sisebenzisa iintlobo zaseJamani zokwenyani. Kwiimvavanyo zelebhu ezikumgangatho ophezulu, ukulahleka kwemveliso yethu ye-Erosion ㎝³ kunokufikelela kwi-0.85 ± 0.01;

2. Ubunzima:

Iithayile zeSiC ziveliswa kwi-ZPC: ubulukhuni obutsha beMohs: 14.55 ± 4.5 (MOR, psi)

3. Ubuninzi:

Uluhlu loxinano lweethayile ze-ZPC SiC lumalunga ne-3.03+0.05.

4. Ubungakanani kunye nomphezulu:

Iithayile zeSiC ezenziwe kwi-ZPC ezingenamifantu kunye neembobo, ezineendawo ezithe tyaba kunye nemiphetho kunye neekona ezingaguqukiyo.

5. Izinto zangaphakathi:

Iiliner/iithayile zesilicon carbide ezingagugiyo zinezixhobo zangaphakathi nezangaphandle ezintle nezifanayo.

If any questions, please feel free to contact us: info@rbsic-sisic.com

■Iinkcukacha:

| Into | Iyunithi | Idatha |

| Ubushushu bokusetyenziswa | ℃ | 1380℃ |

| Uxinano | G/cm3 | >3.02 |

| I-Porosity evulekileyo | % | 0.1 |

| Amandla okugoba -A | I-Mpa | 250 (20℃) |

| Amandla okugoba -B | I-MPa | 280 (1200℃) |

| Imodulus ye-elasticity-A | I-GPa | 330(20℃) |

| Imodulus yokuthamba -B | I-GPa | 300 (1200℃) |

| Ukuqhuba kobushushu | W/mk | 45 (1200℃) |

| I-coefficient yokwandiswa kobushushu | K-1 ×10-6 | 4.5 |

| Ukuqina | / | 13 |

| I-alkaline engangeni asidi | / | ibalasele kakhulu |

■Imilo kunye nobukhulu obufumanekayo:

Ubukhulu: ukusuka kwi-6mm ukuya kwi-25mm

Imilo eqhelekileyo: Ipleyiti ye-SISIC, iPipe ye-SISIC, iiSiSiC Three Links, i-SISIC Elbow, i-SISIC Cone Cyclone.

Isaziso: Ezinye iisayizi kunye nemilo ziyafumaneka xa ziceliwe.

■Ukupakisha:

Kwibhokisi yebhokisi, ipakishwe kwipalethi yomthi efunxwayo enobunzima obuyi-20-24MT/20′FCL.

■Iingenelo eziphambili:

1. Ukumelana nokuguguleka okugqwesileyo, ukumelana neempembelelo kunye nokumelana nokugqwala;

2. Ukuthe tyaba okugqwesileyo kunye nokumelana okuhle kobushushu ukuya kuthi ga kwi-1350℃

3. Ukufakelwa okulula;

4. Ubomi benkonzo ende (bungaphezulu ngokuphindwe kasixhenxe kunobo be-alumina ceramic kwaye bungaphezulu ngokuphindwe kalishumi kunobo be-alumina ceramic

i-polyurethane

Ipateni yokukrala kwempembelelo ye-engile Ukukrala okutyibilikayo kwe-engile ephantsi

Xa ukuhamba kwezinto ezirhabaxa kubetha umphezulu ogugileyo kwi-engile enganzulu okanye kudlula ngaxeshanye nawo, uhlobo lokuguguleka oluvela kwi-frocchini lubizwa ngokuba yi-sliding abrasion.

Iiceramics ze-silicon carbide eziphambili zibonelela ngokumelana nokuguguleka kunye nokumelana nokugqwala kweethayile ze-ceramic kunye ne-lining. Ezi mveliso ziye zangqinwa ukuba ziguguleka kwezixhobo kwinkqubo yokuhambisa, yokucubungula, kunye neyokugcina. Iithayile zethu zinokuveliswa ngobukhulu obuvela kwi-8 ukuya kwi-45mm. Kubalulekile ukuqinisekisa ukuba unokufumana iimveliso ezifunekayo. I-SiSiC: Ubunzima bukaMoh buyi-9.5 (Ubunzima bukaMoh obutsha buyi-13), bunokumelana okuhle nokukhukuliseka kunye nokugqwala, ukukrala okugqwesileyo - ukumelana nokuchasana ne-oxidation. Bunamandla ngokuphindwe ka-4 ukuya ku-5 kune-nitride bonded silicon carbide. Ubomi benkonzo bubude ngokuphindwe ka-5 ukuya ku-7 kune-alumina material. I-MOR ye-RBSiC iphindwe ka-5 ukuya ku-7 kune-SNBSC, ingasetyenziselwa iimilo ezintsonkothileyo. I-lining ye-ceramic enganyangekiyo iyasebenza ukuphucula ukusebenza kwemveliso, ukusebenza kakuhle, ukunciphisa iindleko zokugcina kunye nokunyusa inzuzo.

Iiceramics ezichanekileyo zinolwazi lwezinto eziphathekayo, ubuchule obusetyenzisiweyo kunye nezakhono zobunjineli. Oku kunokuqinisekisa ngokufanelekileyo ukuba izisombululo ezilungileyo zinikezelwa kubathengi bethu. Iithayile ze-silicon carbide ceramic kunye ne-lining zihlala zisetyenziswa kwizicelo ezifana nee-cyclones, iityhubhu, ii-chutes, ii-hoppers, iipayipi, ii-conveyor belts kunye neenkqubo zemveliso. Kwinkqubo, kukho izinto ezihambayo ezityibilikayo phezu komphezulu. Xa into ityibilika kwisixhobo, idlakadlaka kancinci iindawo kude kungabikho nto isalayo. Kwiindawo ezigugileyo kakhulu, oku kunokwenzeka rhoqo kwaye kubangele iingxaki ezininzi ezibizayo. Isakhiwo esiphambili sigcinwa ngokusebenzisa izinto eziqinileyo kakhulu, ezifana neeceramics ze-silicon carbide kunye neeceramics ze-alumina njenge-lining yokuzinikela. Kwangaxeshanye, iiceramics ze-silicon carbide zinokunyamezela ukugugileka ixesha elide ngaphambi kokuba zifune ukutshintshwa, ubomi benkonzo ye-silicon carbide ceramic bubude obuphindwe ka-5 ukuya ku-7 kunezinto ze-alumina.

Iithayile zeCeramic zeSilicon Carbide eziKhuselekileyo kunye neePropati zeLining:

Ayinakhemikhali

Iyakhusela umbane

Ukukhukuliseka koomatshini kunye nokungagugi kakuhle

Ingatshintshwa

Iingenelo zeethayile kunye neeLinings ezimelana nokunxitywa yiCeramic:

Ingasetyenziswa apho kufuneka khona ukunyamezelana okuqinileyo okanye imiphetho emincinci

Ingasetyenziselwa ukuphinda iveze iindawo ezigugileyo ezikhoyo

Ingasetyenziswa ngeendlela ezininzi zokuncamathisela ezifana nokuwelda kunye nezincamathelisi

Yenzelwe ngokwezifiso izicelo ezithile

Ayinakumelana nokugqwala kakhulu

Isisombululo sokunciphisa ukuguguleka kancinci

Ikhusela iindawo ezihambayo ezichaphazeleka kakhulu ziimeko ezigugileyo

Ihlala ixesha elide kwaye isebenza ngcono kunezisombululo zokunciphisa ukuguguleka

Ubushushu obuphezulu kakhulu bokusetyenziswa ukuya kuthi ga kwi-1380°C

1、 Isityalo sentsimbi nentsimbi: 1, umatshini wokuxuba idrama 2, irabha yeseramikhi egqunywe ngedrama 3, i-impeller yefeni 4, i-disc feeder, umkhombe wezinto ezomileyo 5, i-coke hopper, i-converter bin, i-coke bin, i-cyclone dust collector.

2、 Isityalo samandla: 1. I-Ball mill outlet, i-mill volute, i-medium speed mill outlet, i-powder pipe elbow, i-cyclone dust collector, i-silo, i-hopper 2, i-coal hopper, i-coarse and fine powder separator, i-coal mill outlet, i-coal conveying hopper 3, i-coal hopper of bridge grab, i-center coal hopper ye-coal digger, i-outlet ye-ball mill, i-inlet kunye ne-outlet ye-coarse and fine powder separator, i-volute ye-powder exhaust 4 Iintlobo ngeentlobo zezitshisi ezithe ngqo, ezijijekileyo nezinyibilikisiweyo zobushushu obuphezulu zeebhoyila ezisebenzisa amalahle; iipayipi kunye neengqiniba ze-ceramic ezidityanisiweyo ezingagugiyo, izitshisi ze-ceramic, iifeni ze-ceramic, ii-ceramic impellers, iivalvu ze-ceramic, njl.njl.; iindawo ezahlukeneyo ezingagugiyo ezifana neebhola zokugaya, imikhono ye-roller, iidiski zokugaya, iithayile zediski, iiringi zokugaya, iibhola ze-nozzle kunye nezinye iindawo ezingagugiyo ze-medium coal mills ezisebenzisa i-medium speed; iipayipi, i-damper engagugiyo kunye neefeni zeenkcukacha ezahlukeneyo zeenkqubo zokususa uthuli kunye nokukhupha uthuthu; Iibhola Zonke iintlobo zemitshini zine (okanye azinazo) iithayile ze-bolt lining, ipleyiti ye-lining, umbhobho ojikelezayo, indandatho yegiya, ibhola yentsimbi ye-chromium alloy ephantsi, njl.njl.; ivili elibethayo, ipleyiti ebethayo, i-guard hook, i-armor, i-separator, umbhobho wegesi we-flue oshushu kakhulu, njl.njl. we-fan coal mill; izixhobo ezifunekayo kwiintlobo ezahlukeneyo zoomatshini bokutyumza.

3, Iphepha lokugaya: 1. Umbhobho wamalahle ocoliweyo

Iimveliso kunye neenkonzo eziphambili: 1. Iipayipi zeseramikhi ezingagugiyo kwimizi-mveliso: zonke iintlobo zeseramikhi ezingagugiyo nezigugiyo ezifakwe amalahle acoliweyo, iintsalela, udaka oluyi-slag, umbhobho wothutho oluyi-slurry, ingqiniba, ingqiniba, isitshisi samalahle esicoliweyo, i-outlet ye-coal mill, isahluli se-cyclone esirhabaxa nesicolekileyo, i-chute, i-hopper, i-storage bin, i-ore dressing barrel ye-mine magnetic separator; 2. Ifeni yeseramikhi engagugiyo: zonke iintlobo ze-impeller yefeni engagugiyo, engagugiyo, engagugiyo kunye ne-volute, kubandakanya ifeni ye-centrifugal, ifeni ye-axial flow, i-static blade, i-impeller yefeni ehlengahlengiswayo ye-blade eshukumayo, ifeni yokufunxa, i-powder exhaust, ifeni yokusila, ifeni yokwahlukanisa umgubo, ifeni yokususa uthuli, ifeni yentloko ye-kiln kunye nefeni yomsila we-kiln, njl.njl.; 3. I-pump kunye ne-valve ye-ceramic engagugiyo: i-ceramic lining, i-pump impeller, i-shell, i-baffle, i-pipe elbow, i-pneumatic ash removal kunye ne-gas transmission valve kunye nezixhobo ze-slurry ezahlukeneyo, i-slag slurry, i-mortar, ii-tailings kunye nezinye iinkqubo zothutho. 4. Iingubo zeseramikhi ezimelana nokuguguleka: zonke iintlobo zeengubo zeseramikhi ezimelana nokuguguleka kunye ne-mastic zisetyenziselwa i-fan volute, i-elbow pipe, i-mill outlet, i-coarse and fine separator pipe, i-chute, i-hopper kunye ne-valve. 5. Izixhobo zokwahlukanisa imagnethi ezimelana nokuguguleka: iindawo zokuhamba kwezixhobo ezahlukeneyo zokucubungula izimbiwa ezomileyo nezimanzi, kubandakanya i-magnetic separator drum, i-bottom groove, i-chute, i-pipeline, ii-mud pumps ezahlukeneyo, i-slurry pump volute, i-impeller, kunye ne-conveyor pipeline. 6. Itekhnoloji yokutshiza umphezulu: kusetyenziswa umbane wamva nje we-inverter pulse arc kunye ne-high-speed arc spraying gun, izixhobo ezahlukeneyo zesinyithi ezimelana nokuguguleka ziyatshizwa kumphezulu we-metal substrate ukwenza umaleko okhuselayo omelana nokuguguleka. Inokubonelela ngokhuseleko olusebenzayo kuzo zonke iintlobo zokuguguleka kokuguguleka okuphakathi.

I-Shandong Zhongpeng ZPC ceramics lishishini eligxile ekuvelisweni kweeseramikhi zoshishino, elisebenza kakhulu kwi-R & D kunye nokuveliswa kweeseramikhi ze-silicon carbide. Singacubungula iimveliso zeseramikhi ngokwemizobo yakho, sigxile ekuvelisweni kwezinto ezinkulu, intonga yeseramikhi echanekileyo kakhulu, umbhobho weseramikhi, iringi yeseramikhi, ipleyiti yeseramikhi, iflangi yeseramikhi, umlomo weseramikhi, kunye neendawo ezilungiselelweyo ezinganyangekiyo ezinobukhulu obukhulu.

I-Shandong Zhongpeng Special Ceramics Co., Ltd yenye yezona zisombululo zinkulu zezinto ezintsha ze-silicon carbide ceramic eTshayina. I-SiC technical ceramic: Ubunzima bukaMoh buyi-9 (Ubunzima bukaMoh obuyi-13), bunokumelana okuhle nokukhukuliseka kunye nokugqwala, ukukrala okugqwesileyo - ukumelana nokubola kunye nokuchasana ne-oxidation. Ubomi benkonzo yemveliso yeSiC bubude obuphindwe ka-4 ukuya ku-5 kune-92% ye-alumina material. I-MOR ye-RBSiC iphindwe ka-5 ukuya ku-7 kune-SNBSC, ingasetyenziselwa iimilo ezinzima ngakumbi. Inkqubo yokucaphula iyakhawuleza, ukuhanjiswa kunjengoko kuthembisiwe kwaye umgangatho awulingani. Sihlala siqhubeka nokuchasa iinjongo zethu kwaye sibuyisela iintliziyo zethu kuluntu.