OEM/ODM China Gpn Flame Cutting Nozzle - SiC bushing, plates, liners and rings – ZhongPeng

OEM/ODM China Gpn Flame Cutting Nozzle - SiC bushing, plates, liners and rings – ZhongPeng Detail:

Please see the product video on the website:

https://www.youtube.com/watch?v=Caqp0Rrfhgo&feature=youtu.be

Wear resistant ceramic linings provide excellent impact and abrasion resistant protection. Specifically constructed for use wherever wear and abrasion are a problem, ZPC® linings reduce downtime and maintenance. The SiC ceramic linings are highly resistant to the abrasive effects of bulk materials such as silica, ore, glass, slag, fly ash, limestone, coal, coke, feed, grain, fertilizer, salt and other highly abrasive materials.

Abrasion resistant and wear resistant linings from Zhongpeng suit many industries. Customers range from the powder industry to the coal, power, mine and food industries where FGD nozzles are approved for use in China Electric Power Group. ZPC wear resistance linings are marketed throughout the United States, Canada, Austrilia, Mexico, South Africa, etc. They are ideal for lining components susceptible to severe abrasion in plant material handling and processing operations. The SiC linings, plates and blocks are effective in applications such as pipes, tees, elbows, separators, cyclones, silos, bunkers, concrete and steel troughs, chutes, impellers and agitators, fan blades and fan casings, conveyor screws, chain conveyors, mixers, pulpers; wherever friction-induced abrasion is a problem.

Abrasion resistant tiles for wear protection, to meet the customer’s specific abrasion, impact and corrosion problems. The use of ZPC SiC wear resistant linings on problematic components adds up to significant savings because of their longer service life. The cost of replacement parts, the downtime of operations, plant clean-up and the cost of maintenance work are all dramatically reduced. The savings incurred will pay for the linings and installation in a short time.

Silicon carbide sic bushing is a new type of high-tech and wear-resistant material in the world. It was made of high-purity silicon carbide powder, high-purity high-temperature carbon black and binders,by pouring, blanking, sintering, and sand-removing processes,made of a composite high wear product.

It is currently used as a bushing in mining equipment,such as copper, gold, iron ore,nickel ore and other in non-ferrous metals.It plays a role of high wear resistance,the wear life is more than 10 times that of conventional steel bushings and alumina bushing.

1.Application of sic bushing in the mining industry

For mine filling, the concentrate powder and tailings transportation has serious wear on the pipeline.The service life of the ore powder conveying pipeline used in the past is less than one year, and now choose silicon carbide bushings can increase the service life by more than 10 times.

2.Why silicon carbide linings are widely used in the mining industry?

Due to the wear resistance of ceramic tubes, following is a comparison of wear resistance of ceramic tubes and other materials.

Comparison of wear resistance of silicon carbide bushings

| Sandblasting contrast test(SiC sand) | 30%SiO2 mud slurry contrast test | ||

| Material | Reduced volume | Material | Reduced volume |

| 97% alumina tube | 0.0025 | 45steel | 25 |

| Silicon carbide bushing | 0.0022 | Silicon carbide bushing | 3 |

3.Other physical and mechanical properties of ceramic wear resistant pipes in the mining industry

| Item data material |

Strength HV kg/mrn2 |

Bending strength MPa |

Surface material | Ceramic layer density g/cm3 |

Compressive shear strength MP | Resistance to mechanical shock | Thermal shock resistance |

| Steel tube | 149 | 411 | |||||

| SiC bushing | 1100-1400 | 300-350 | smooth | 3.85-3.9 | 15-20 | 15 | 900 |

4.Another feature of silicon carbide bushings used in mines – small loss of running resistance

Test on resistance characteristics of powder, slag and ash transportation,the results are as follows:

| Material | Absolute roughness (△) | Absolute roughness(△/D) | Water resistance coefficient | ||

| Hydraulic transmission | Pneumatic conveying | Hydraulic transmission | Pneumatic conveying | ||

| Ordinary steel tube | 0.119 | 0.20 | 7.935×104 | 1.343×103 | 0.195 |

| Ceramic composite pipe | 0.117 | 0.195 | 7.935×104 | 1.343×103 | 0.0193 |

5.Silicon carbide bushing connection

(1)When flexible pipes are used to connect the installation pipes, the insertion lengths of the two ends of the flexible pipe sleeve must be adjusted symmetrically. Expansion gap should be based on local conditions or design department requirements.

(2)When When using flange connection, the flange face must be flush with the end face of the composite pipe

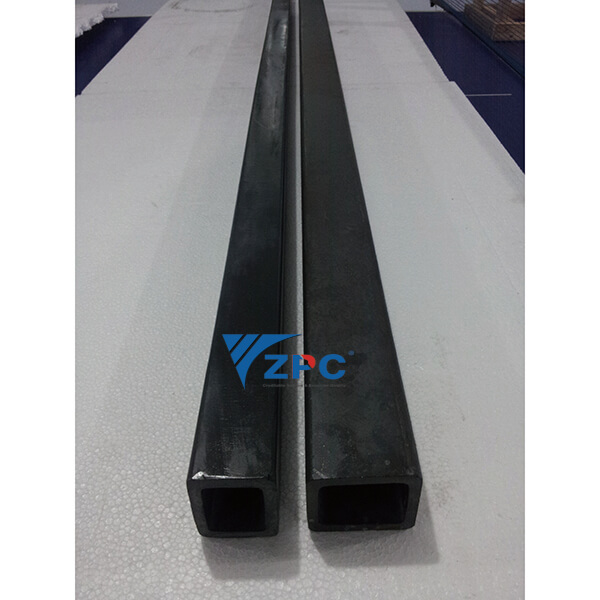

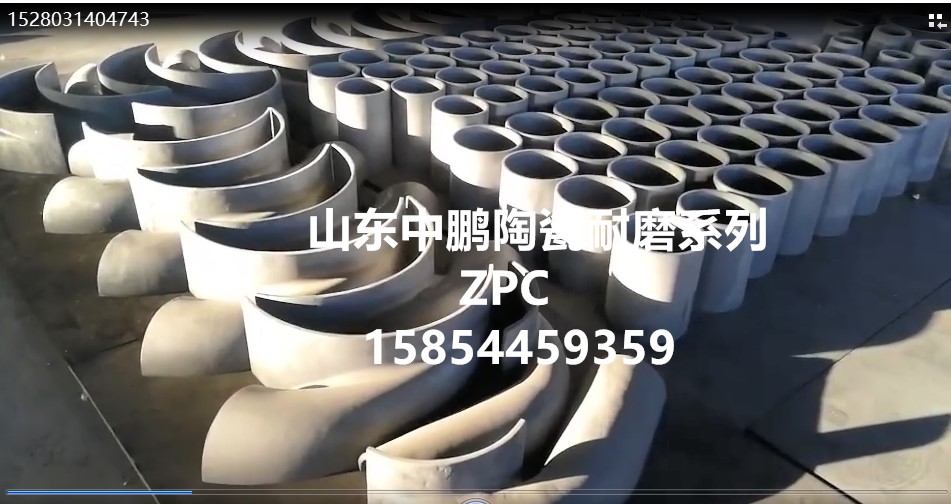

Product detail pictures:

Related Product Guide:

Industrail SiC Crucibles and Saggers – Keep Your Business Warm

Wear resistance block, plates and inner lining

OEM/ODM China Gpn Flame Cutting Nozzle - SiC bushing, plates, liners and rings – ZhongPeng, The product will supply to all over the world, such as: , , ,

Shandong Zhongpeng Special Ceramics Co., Ltd is one of the largest silicon carbide ceramic new material solutions in China. SiC technical ceramic: Moh’s hardness is 9 (New Moh’s hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. SiC product’s service life is 4 to 5 times longer than 92% alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. The quotation process is quick, the delivery is as promised and the quality is second to none. We always persist in challenging our goals and give our hearts back to society.