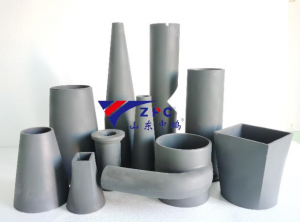

Reaction sintered silicon carbide ceramics are a high-tech industrial ceramic material that possesses several unmatched properties, including high temperature strength, strong oxidation resistance, strong acid and alkali corrosion resistance, good thermal stability, high thermal conductivity, high wear resistance, and hardness second only to diamond. This material has been extensively processed into several different products, such as silicon carbide flame nozzle burner sleeves, silicon carbide beam rollers, silicon carbide cold air pipes, silicon carbide radiant tubes, silicon carbide preheating pipe air guide sleeves, silicon carbide sandblasting nozzles, silicon carbide desulfurization nozzles, silicon carbide wear-resistant linings, and more. These products have proved to be very useful in a variety of industries, including electric power, steel, ceramics, high-temperature equipment, petroleum, chemical industry, environmental protection, and machinery manufacturing, and have been widely recognized by all walks of life.

One of the most popular products in the line of reaction sintered silicon carbide ceramics is silicon carbide flame nozzle burner sleeves. This product is specially designed for high-temperature kilns, such as roller kilns, tunnel kilns, and shuttle kilns. The silicon carbide flame nozzle burner sleeve has a high temperature strength that withstands temperatures without breaking or deformation. Moreover, it has rapid cooling and heat resistance, making it ideal for controlling temperature balance in the kiln. The flame nozzle burner sleeve has been widely used in the firing of porcelain, sanitary porcelain, architectural ceramics, and other high-temperature kilns.

Another significant application of reaction sintered silicon carbide ceramics is in desulfurization nozzles used in thermal power plants, large boilers, and complete sets of desulfurization and dust removal devices. The localization of silicon carbide desulfurization nozzles has replaced imported products, making it a cost-effective solution with the same quality standards. Compared to other materials, the silicon carbide desulfurization nozzle has high strength, hardness, strong corrosion resistance, high temperature resistance, and is highly resistant to wear, making it ideal for use in harsh conditions. The commonly used types are mainly spiral nozzles and vortex nozzles.

Additionally, when it comes to desulfurization nozzles, the spiral nozzles stand out. The outer layer of the nozzle is spiral, which helps in providing a more even and effective cleaning. Moreover, the wear resistance of the nozzle is higher than other materials, reducing the need for maintenance. Furthermore, it has excellent performance in terms of corrosion, temperature resistance, and wear resistance, making it suitable for long-term use in harsh environments.

In conclusion, reaction sintered silicon carbide ceramics have found numerous applications in various industries and have become a popular choice due to their unmatched properties. Silicon carbide flame nozzle burner sleeves and silicon carbide desulfurization nozzles highlight just a few applications for this material. So, if you are looking for a material that with outstanding wear resistance, corrosion resistance, high temperature resistance, and extraordinary durability, reaction sintered silicon carbide ceramics should be a top consideration.

Post time: Jun-09-2023