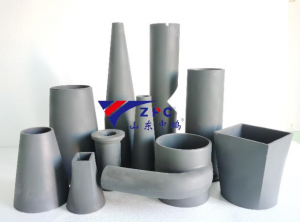

Iiceramics ze-silicon carbide ezisebenzisa i-reaction sintered zizinto ze-ceramic zobugcisa obuphezulu ezinezinto ezininzi ezingenakuthelekiswa nanto, kubandakanya amandla obushushu aphezulu, ukumelana okunamandla kwe-oxidation, ukumelana okunamandla kwe-asidi kunye nokugqwala kwe-alkali, ukuzinza okuhle kobushushu, ukuqhuba okuphezulu kobushushu, ukumelana nokugqwala okuphezulu, kunye nobunzima obulandelayo kuphela kwidayimani. Ezi zinto zicutshungulwe kakhulu kwiimveliso ezahlukeneyo, ezifana nee-sleeves ze-silicon carbide flame nozzle burner, ii-rollers ze-silicon carbide beam, iipayipi zomoya obandayo we-silicon carbide, iityhubhu ze-silicon carbide radiant, ii-sleeves ze-silicon carbide preheating pipe air guide, ii-nozzles ze-silicon carbide sandblasting, ii-nozzles ze-silicon carbide desulfurization, ii-linings ze-silicon carbide ezinganyangekiyo, kunye nokunye. Ezi mveliso zibonakalise ukuba ziluncedo kakhulu kumashishini ahlukeneyo, kubandakanya amandla ombane, intsimbi, ii-ceramics, izixhobo zobushushu obuphezulu, i-petroleum, imboni yeekhemikhali, ukhuseleko lokusingqongileyo, kunye nokuveliswa koomatshini, kwaye ziye zaqatshelwa ngokubanzi kuzo zonke iindlela zobomi.

Enye yezona mveliso zidumileyo kuluhlu lweeseramiki zesilicon carbide ezisetyenziswa yi-reaction yi-silicon carbide flame nozzle burner sleeves. Le mveliso yenzelwe ngokukodwa ii-oven ezishushu kakhulu, ezifana nee-roller kilns, ii-tunnel kilns, kunye nee-shuttle kilns. I-silicon carbide flame nozzle burner sleeve inamandla aphezulu obushushu amelana namaqondo obushushu ngaphandle kokuphuka okanye ukuguquka. Ngaphezu koko, inokupholisa ngokukhawuleza kunye nokumelana nobushushu, okwenza ukuba ilungele ukulawula ibhalansi yobushushu kwi-oven. I-flame nozzle burner sleeve isetyenziswa kakhulu ekutshiseni i-porcelain, i-porcelain yococeko, ii-ceramics zokwakha, kunye nezinye ii-oven ezishushu kakhulu.

Olunye uhlobo olubalulekileyo lwe-reaction sintered silicon carbide ceramics lukwi-desulfurization nozzles ezisetyenziswa kwi-thermal power plants, kwi-boilers ezinkulu, nakwiiseti ezipheleleyo ze-desulfurization kunye nezixhobo zokususa uthuli. Indawo ye-silicon carbide desulfurization nozzles ithathe indawo yeemveliso ezingenisiweyo, nto leyo eyenza ukuba ibe sisisombululo esingabizi kakhulu esinemigangatho efanayo yomgangatho. Xa kuthelekiswa nezinye izixhobo, i-silicon carbide desulfurization nozzle inamandla aphezulu, ubulukhuni, ukumelana nokugqwala okunamandla, ukumelana nobushushu obuphezulu, kwaye ayigugi kakhulu, nto leyo eyenza ukuba ilungele ukusetyenziswa kwiimeko ezinzima. Iintlobo ezisetyenziswa rhoqo zii-spiral nozzles kunye ne-vortex nozzles.

Ukongeza, xa kufikwa kwimilomo ye-desulfurization, imilomo ye-spiral iyagqama. Umaleko wangaphandle we-nozzle yi-spiral, enceda ekuboneleleni ngokucoca okulinganayo nokusebenzayo. Ngaphezu koko, ukumelana nokuguguleka kwe-nozzle kuphezulu kunezinye izixhobo, nto leyo enciphisa isidingo sokugcinwa. Ngaphezu koko, isebenza kakuhle kakhulu ngokubhekiselele ekungcoleni, ukumelana nobushushu, kunye nokumelana nokuguguleka, okwenza ukuba ifaneleke ukusetyenziswa ixesha elide kwiindawo ezinzima.

Ukuqukumbela, iiceramics zesilicon carbide ezisebenzisa i-reaction sintered zifumene izicelo ezininzi kumashishini ahlukeneyo kwaye ziye zaba lukhetho oludumileyo ngenxa yeempawu zazo ezingenakuthelekiswa nanto. Iisleeve zeSilicon carbide flame nozzles burner kunye nee-silicon carbide desulfurization nozzles zibonisa nje izicelo ezimbalwa zale nto. Ke, ukuba ujonge izinto ezinokumelana nokuguguleka okugqwesileyo, ukumelana nokugqwala, ukumelana nobushushu obuphezulu, kunye nokuqina okumangalisayo, iiceramics zesilicon carbide ezisebenzisa i-reaction sintered kufuneka zibe yeyona nto iphambili ekufuneka iqwalaselwe.

Ixesha lokuthumela: Juni-09-2023