In many aspects of industrial production, equipment wear and tear has always been a key factor affecting production efficiency and cost. In order to solve this problem, various wear-resistant materials have emerged, among which silicon carbide wear-resistant lining has gradually become the “new favorite” in the industrial field due to its excellent performance. Today, let’s delve into this magical material.

1、 What is silicon carbide wear-resistant lining?

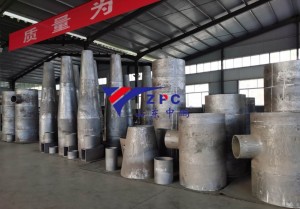

Silicon carbide (SiC) is a compound composed of silicon and carbon, with a unique and stable crystal structure. Its basic structural units are interwoven SiC and CSi tetrahedra. Silicon carbide wear-resistant lining is a protective layer made of silicon carbide material to protect the interior of equipment from wear and tear. It can be made into various shapes, such as ceramic rings, ceramic liners, etc., and then installed on the inner walls of equipment such as pipelines, pump bodies, and silos that are prone to material erosion and friction.

2、 Advantages of silicon carbide wear-resistant lining

1. High hardness and super wear resistance: The hardness of silicon carbide ceramics is very high, second only to the hardest diamond in nature. This high hardness gives it extremely strong wear resistance, able to withstand high-speed erosion and strong friction of materials, greatly extending the service life of equipment, making it an ideal wear-resistant material in the field of heavy wear. Compared to other ordinary wear-resistant materials, silicon carbide wear-resistant lining has significant advantages in wear resistance, which can reduce the frequency of equipment maintenance and replacement for enterprises and lower production costs.

2. Low density and light weight: Silicon carbide has a much lower density than metals such as steel. For example, the density of reaction sintered silicon carbide ceramics is only 3.0g/cm ³, while the density of pressureless sintered silicon carbide ceramics is 3.14-3.0g/cm ³. In the case of the same volume, the weight of silicon carbide wear-resistant lining is lighter, which not only facilitates transportation and installation, but also reduces the mechanical load of equipment, making equipment operation easier, and enabling the installation of pipelines and other equipment to be higher and farther.

3. High temperature resistance: It has good thermal stability and the unique crystal structure of silicon carbide allows it to withstand high temperatures, with a sintering temperature of up to 1350 ℃. This characteristic enables the silicon carbide wear-resistant lining to maintain stable performance even in high temperature environments, without deformation or damage due to high temperatures, making it suitable for various high-temperature industrial scenarios such as metallurgy, power and other industries.

4. Corrosion resistance: Silicon carbide has stable chemical properties and can exhibit good corrosion resistance in the face of various chemical substances. Whether in the transportation of strong acidic and alkaline media in chemical production or in the field of environmental protection such as sewage treatment, silicon carbide wear-resistant lining can reliably protect equipment, prevent equipment from being corroded by chemical substances, and extend the service life of equipment.

5. Weak conductivity and anti-static: Silicon carbide ceramics have weak conductivity, which makes them suitable for applications with strict requirements for static electricity, such as explosion-proof workshops. In these environments, static electricity may cause serious safety accidents, and the anti-static function of silicon carbide wear-resistant lining can effectively prevent the accumulation of static electricity and ensure production safety.

6. Easy to form, capable of processing large and complex shaped parts: Silicon carbide can be processed using processes such as reaction sintering, which gives it great advantages in forming. Through this process, large-sized ceramics and structurally complex shaped ceramics can be produced. This means that no matter how special the shape and size of the equipment are, the silicon carbide wear-resistant lining can be well adapted to meet the needs of different industrial equipment.

Silicon carbide wear-resistant lining has demonstrated tremendous application value in the industrial field due to its numerous advantages. With the continuous development and progress of materials science, it is believed that silicon carbide wear-resistant lining will be applied in more fields, providing stronger support for the efficient and stable operation of industrial production. If you are interested in silicon carbide wear-resistant lining, please feel free to contact us at any time to explore more secrets about silicon carbide ceramics together.

Post time: Jun-02-2025