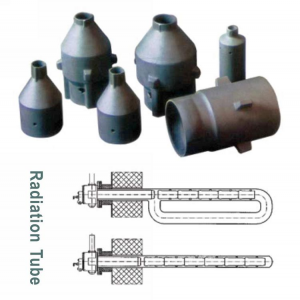

Siliziumkarbid-Strahlungsrohr

SiliciumcarbidprodukteDie am besten geeigneten Ofeneinrichtungen für Tunnelöfen, Shuttle-Öfen und Rollenöfen mit Herd sind die Flammrohre.

Hohe Wärmeleitfähigkeit bei hohen Temperaturen, gute und schnelle Abkühlung bei Hitze, gute Oxidationsbeständigkeit, gute Temperaturwechselbeständigkeit und lange Lebensdauer.

Merkmale:

• Hervorragende Energieeinsparungen.

• Geringeres Gewicht und höhere Tragfähigkeit.

• Ausgezeichnete Verformungsbeständigkeit bei hohen Temperaturen.

• Hohe Wärmeleitfähigkeit

• Hoher Elastizitätsmodul

• Niedriger Wärmeausdehnungskoeffizient

• Extrem hohe Härte

• Verschleißfest

Anwendung:

• Sanitärkeramik

• Brennofenmöbel-Tiegel

• Glasplattenindustrie

• Gleitlager

• Glanzbrand von Geschirr.

• Wärmetauscher

• Brenner

• Verschleißteile (Gewindeführungen)

RBSiC(SiSiC)-Düsen werden für die Hochtemperatursysteme von Tunnelöfen, Shuttle-Öfen und vielen anderen Anlagen verwendet.

andere Industrieöfen. RBSiC(SiSiC)-Querträger weisen eine höhere Festigkeit auf und verformen sich auch bei sehr hohen Temperaturen nicht.

Spezifikation

| Eigenschaften | Einheiten | Siliziumkarbid-Material | ||||||

| Typ | SiC | SiSiC | NSiC | RSiC | ||||

| Chemische Zusammensetzung | SiC% | 89 | 87 | 92 | 70 | 99 | ||

| SiO2 % | 5 | 6 | - | Si3N4 28 | - | |||

| Al2O3% | 1.0 | 2.0 | - | - | - | |||

| Massendichte | g/cm³ | 2,85 | 2.8 | 3.01 | 2.8 | 2,75 | ||

| Scheinbare Porosität | % | 12 | 14 | 0,1 | 12 | 14 | ||

| MOR@20℃ | MPa | 50 | 48 | 260 | 180 | 100 | ||

| MOR@1300℃ | MPa | 58 | 56 | 280 | 185 | 120 | ||

| CTE@20℃-1000℃ | 10-6K-1 | 4.8 | 4.2 | 4,5 | 4.7 | 4.6 | ||

| CCS | MPa | 100 | 90 | 900 | 500 | 300 | ||

| Beständigkeit gegen Temperaturschocks | ★ | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★★ | ||

RBSiC(SiSiC)-Düsen/Träger/Walzen werden für die Beladungsstruktursysteme von Tunnelöfen, Shuttle-Öfen und vielen anderen Anlagen verwendet.

andere Industrieöfen. RBSiC(SiSiC)-Querträger weisen eine höhere Festigkeit auf und verformen sich auch bei sehr hohen Temperaturen nicht.

Die Träger zeichnen sich zudem durch eine lange Lebensdauer aus. Sie eignen sich optimal als Ofenausstattung für Sanitärkeramik und Elektrokeramik. RBSiC (SiSiC) besitzt eine ausgezeichnete Wärmeleitfähigkeit und ermöglicht so Energieeinsparungen bei gleichzeitig geringerem Gewicht des Ofenwagens.

Verpackung & Versand

1,50 Stück in einer Holzkiste (vollständig umschlossen, sicher und geschützt)

2.800 kg bis 1.000 kg /Holzkiste.

3. Antikollisionsschutz wie z. B. Schaumstoffplatten

4,3-lagige Holzverbundplatte, robust, stoßfest, sturzfest

Versanddetails

1. Professioneller Autotransport zu verschiedenen Häfen in China, anschließend Verladung durch eine professionelle Spedition.

2. Sowohl FOB als auch CIF können flexibel abgewickelt werden.

3. Wettbewerbsfähige Seefrachtkosten und kurze Transitzeiten.

Shandong Zhongpeng Special Ceramics Co., Ltd. ist einer der größten Anbieter von Siliziumkarbid-Keramiklösungen in China. Die technische SiC-Keramik weist eine Mohs-Härte von 9 (neue Mohs-Härte: 13) auf und zeichnet sich durch hervorragende Beständigkeit gegen Erosion und Korrosion, Abriebfestigkeit und Oxidation aus. Die Lebensdauer von SiC-Produkten ist 4- bis 5-mal länger als die von 92%igem Aluminiumoxid. Die Biegefestigkeit (MOR) von RBSiC ist 5- bis 7-mal höher als die von SNBSC, wodurch sich komplexere Formen realisieren lassen. Wir bieten schnelle Angebotserstellung, pünktliche Lieferung und höchste Qualität. Wir stellen uns stets neuen Herausforderungen und engagieren uns für die Gesellschaft.