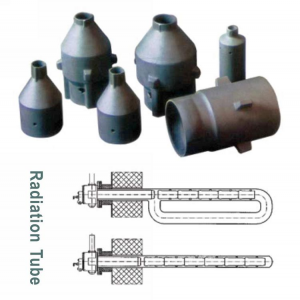

실리콘 카바이드 방사관

탄화규소 제품화염관으로서 터널 가마, 셔틀 가마, 하스 가마의 롤러 가마에 가장 적합한 가마 가구는 무엇입니까?

고온 열전도도가 우수하고, 내열성이 좋고, 냉각 속도가 빠르며, 산화에 대한 저항성, 열충격에 대한 저항성이 좋고, 수명이 길다.

특징:

• 뛰어난 에너지 절감 효과.

• 무게가 가볍고 하중 용량이 더 큽니다.

• 고온에서의 뛰어난 변형 저항성.

• 높은 열전도도

• 높은 영률

• 낮은 열팽창 계수

• 매우 높은 경도

• 내마모성

애플리케이션:

• 위생도기

• 가마 가구 도가니

• 유리 패널 산업

• 슬라이딩 베어링

• 식기의 광택 소성.

• 열교환기

• 버너

• 마모 부품(나사 가이드)

RBSiC(SiSiC) 노즐은 터널 가마, 셔틀 가마 및 기타 고온 시스템에 사용됩니다.

다른 산업용 가마. RBSiC(SiSiC) 크로스 보는 강도가 더 높고 매우 높은 온도에서도 변형이 없습니다.

사양

| 속성 | 단위 | 탄화규소 소재 | ||||||

| 유형 | SiC | 시시크 | 엔씨아이씨 | RSiC | ||||

| 화학 성분 | SiC% | 89 | 87 | 92 | 70 | 99 | ||

| SiO2 % | 5 | 6 | - | Si3N4 28 | - | |||

| Al2O3% | 1.0 | 2.0 | - | - | - | |||

| 대량 욕망 | g/cm3 | 2.85 | 2.8 | 3.01 | 2.8 | 2.75 | ||

| 겉보기 다공성 | % | 12 | 14 | 0.1 | 12 | 14 | ||

| 20℃에서 20℃까지 | MPa | 50 | 48 | 260 | 180 | 100 | ||

| 1300℃에서 MOR | MPa | 58 | 56 | 280 | 185 | 120 | ||

| 열팽창계수@20℃-1000℃ | 10-6K-1 | 4.8 | 4.2 | 4.5 | 4.7 | 4.6 | ||

| CCS | MPa | 100 | 90 | 900 | 500 | 300 | ||

| 열충격 저항성 | ★ | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★★ | ||

RBSiC(SiSiC) 노즐/빔/롤러는 터널 가마, 셔틀 가마 및 많은 가마의 로딩 구조 시스템에 사용됩니다.

다른 산업용 가마. RBSiC(SiSiC) 크로스 보는 강도가 더 높고 매우 높은 온도에서도 변형이 없습니다.

또한, 빔은 긴 작동 수명을 자랑합니다. 이 빔은 위생복 및 전기 도자기 제작에 가장 적합한 가마 가구입니다. RBSiC(SiSiC)는 열전도율이 뛰어나 가마 차량의 무게를 줄여 에너지를 절약할 수 있습니다.

포장 및 배송

1.50개씩 나무상자에 담겨 있습니다(완전히 밀봉되어 있어 안전합니다)

2.800kg~1000kg / 나무 상자.

3.폼보드 등 충돌방지 보호

4.3층 목재 복합 패널, 견고하고 충격에 강하며 낙하에도 강함

배송 세부 정보

1. 중국의 다양한 항구로 자동차를 전문적으로 운송한 후, 전문 운송회사를 통해 화물을 적재합니다.

2. FOB와 CIF 모두 유연하게 운영 가능합니다.

3. 경쟁력 있는 해상 운송과 짧은 운송 시간.

산둥 중펑 특수 세라믹스(Shandong Zhongpeng Special Ceramics Co., Ltd)는 중국 최대 규모의 실리콘 카바이드 세라믹 신소재 솔루션 기업 중 하나입니다. SiC 기술 세라믹은 모스 경도 9(신 모스 경도 13)로, 내식성, 내마모성, 내산화성이 뛰어납니다. SiC 제품은 92% 알루미나 소재보다 4~5배 더 긴 수명을 자랑합니다. RBSiC의 MOR은 SNBSC의 5~7배로, 더욱 복잡한 형상에도 적용 가능합니다. 견적은 빠르고, 납기는 약속대로, 품질은 최고 수준입니다. 당사는 항상 목표에 도전하며, 사회에 기여하고자 합니다.