China Factory for Sand Blast Abrasive Silicon Carbide - RBSiC hydrocyclone liner – ZhongPeng

China Factory for Sand Blast Abrasive Silicon Carbide - RBSiC hydrocyclone liner – ZhongPeng Detail:

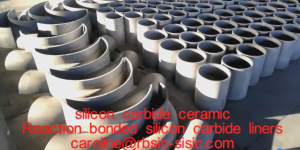

Reaction bonded silicon carbide is made by infiltrating compact made of mixtures of SiC and carbon with liquid silicon. The silicon reacts with the carbon forming more SiC which bonds the initial SiC particles. Reaction bonded silicon carbide has excellent wear, impact and chemical resistance. It can be formed into a variety of shapes, including cone and sleeve shapes, as well as more complex engineered pieces designed for equipment involved in mineral processing industry.

Application

- Hydrocyclone Linings

- Apexes

- Vessel and Pipe Linings

- Chutes

- Pumps

- Nozzles

- Burner Tiles

- Impeller Rings

Our company also offers an extensive range of industrial cyclone lining (liner). Cyclone mining equipment, supplies and systems widely used in the mining of coal, railway, port, power, iron & steel and cement industries. ZPC custom design and build mining cyclone liners.

The reaction-sintered silicon carbide ceramic bushings are characterized by high hardness, wear resistance, impact resistance, high temperature resistance, and resistance to acid and alkali corrosion. Its actual service life is more than 7 times that of polyurethane materials and more than 5 times that of alumina materials. This product is suitable for mining industry, mixing industry and others with the characteristics of strong corrosion, coarse particle classification, concentration, dehydration and so on. In the coal, water conservancy, and oil exploration industries, this product also has a wide range of applications. For example, silicon carbide ceramic cones, elbows, tees, arc plate patches, liners, silicon carbide cyclone linings, etc., are particularly suitable for beneficiation industries.

Product detail pictures:

Related Product Guide:

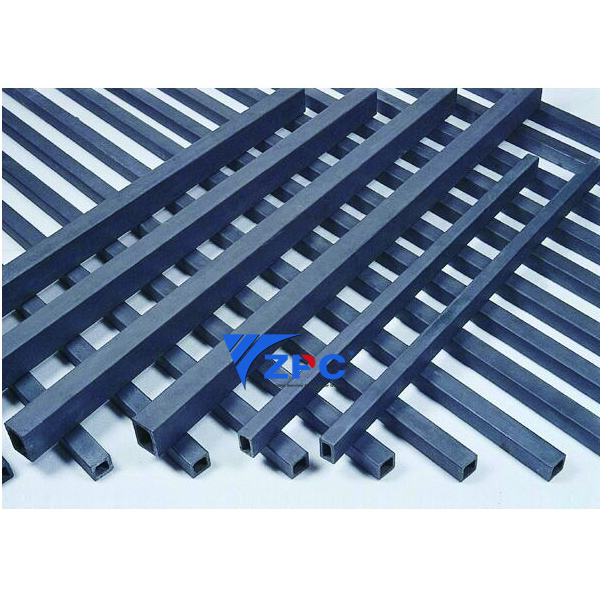

Silicon Carbide Ceramics for Industry

Wear resistance SiC ceramic inner lining

China Factory for Sand Blast Abrasive Silicon Carbide - RBSiC hydrocyclone liner – ZhongPeng, The product will supply to all over the world, such as: , , ,

Shandong Zhongpeng Special Ceramics Co., Ltd is one of the largest silicon carbide ceramic new material solutions in China. SiC technical ceramic: Moh’s hardness is 9 (New Moh’s hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. SiC product’s service life is 4 to 5 times longer than 92% alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. The quotation process is quick, the delivery is as promised and the quality is second to none. We always persist in challenging our goals and give our hearts back to society.