Ishubhu ekhanyayo ye-silicon carbide

Imikhiqizo ye-silicon carbideifenisha ye-oven efaneleka kakhulu yama-tunnel kilns, ama-shuttle kilns, ama-roller of hearth kilns njengama-flame tubes.

Ngokushisa okuphezulu, ukupholisa okuhle, okusheshayo ekumelaneni nokushisa, ukumelana ne-oxidation, ukumelana nokushaqeka kokushisa okuhle, impilo ende.

Izici:

• Ukonga amandla okuhle kakhulu.

• Isisindo esilula kanye nomthamo womthwalo ophezulu.

• Ukumelana okuhle kakhulu nokuhlanekezela ekushiseni okuphezulu.

• Ukushisa okuphezulu

• I-modulus ye-High Young

• Isilinganiso sokwanda kokushisa esiphansi

• Ubulukhuni obuphezulu kakhulu

• Ukumelana nokuguguleka

Isicelo:

• izinto zokuhlanzeka

• Izitsha zokushisela ifenisha yehhavini

• izimboni zamaphaneli engilazi

• Amabheringi ashelelayo

• ukushiswa kwetafula okukhazimulayo.

• Izishintshi zokushisa

• Izitofu

• Izingxenye zokugqoka (iziqondiso zemicu)

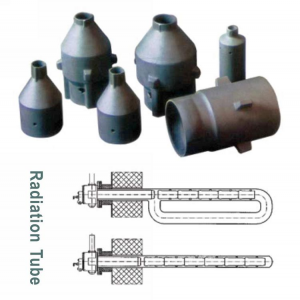

Ama-nozzle e-RBSiC(SiSiC) asetshenziselwa izinhlelo zokushisa okuphezulu zama-tunnel kilns, ama-shuttle kilns kanye nezinye eziningi

amanye ama-oven ezimboni. Imishayo ye-RBSiC(SiSiC) inamandla aphezulu futhi azikho izinguquko ngisho noma izinga lokushisa liphezulu kakhulu.

Imininingwane

| Izakhiwo | Amayunithi | Izinto ze-silicon carbide | ||||||

| Uhlobo | I-SiC | I-SiSiC | I-NSiC | I-RSiC | ||||

| Ukwakheka kwamakhemikhali | I-SiC% | 89 | 87 | 92 | 70 | 99 | ||

| I-SiO2 % | 5 | 6 | - | I-Si3N4 28 | - | |||

| I-Al2O3% | 1.0 | 2.0 | - | - | - | |||

| Ubukhulu Obuningi | g/cm3 | 2.85 | 2.8 | 3.01 | 2.8 | 2.75 | ||

| Ukuvuleka okubonakalayo | % | 12 | 14 | 0.1 | 12 | 14 | ||

| MOR@20℃ | I-MPa | 50 | 48 | 260 | 180 | 100 | ||

| MOR@1300℃ | I-MPa | 58 | 56 | 280 | 185 | 120 | ||

| I-CTE@20℃-1000℃ | 10-6K-1 | 4.8 | 4.2 | 4.5 | 4.7 | 4.6 | ||

| I-CCS | I-MPa | 100 | 90 | 900 | 500 | 300 | ||

| Ukumelana nokushaqeka kokushisa | ★ | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★★ | ||

Ama-nozzle/ama-beam/ama-roller e-RBSiC(SiSiC) asetshenziselwa izinhlelo zesakhiwo sokulayisha sama-tunnel kilns, ama-shuttle kilns kanye nezinye eziningi.

amanye ama-oven ezimboni. Imishayo ye-RBSiC(SiSiC) inamandla aphezulu futhi azikho izinguquko ngisho noma izinga lokushisa liphezulu kakhulu.

Futhi imishayo ibonisa ukusebenza isikhathi eside. Imishayo iyifenisha yehhavini efaneleka kakhulu yezingubo zangasese kanye nezicelo ze-porcelain kagesi. I-RBSiC (SiSiC) inokushisa okuhle kakhulu, ngakho-ke iyatholakala ukuze yonge amandla ngesisindo esincane semoto yehhavini.

Ukupakisha Nokuthumela

Izingcezu ezingu-1.50 ebhokisini lokhuni (elivalwe ngokuphelele, eliphephile futhi elivikelekile)

2.800kg ~ 1000kg /ibhokisi lokhuni.

3. Ukuvikelwa kokungqubuzana okufana nebhodi le-foam

Iphaneli ehlanganisiwe yokhuni enezingqimba ezingu-4.3, eqinile, engashayisani, engawi

Imininingwane yokuthumela

1. Ukuthuthwa kwezimoto zobungcweti eziya emachwebeni ahlukahlukene eShayina, bese kulayishwa yinkampani yokuthumela echwepheni.

2. Kokubili i-FOB ne-CIF kungasetshenziswa kalula.

3. Imithwalo yolwandle encintisanayo kanye nesikhathi esifushane sokuhamba.

I-Shandong Zhongpeng Special Ceramics Co., Ltd ingenye yezixazululo ezinkulu zezinto ezintsha ze-silicon carbide ceramic eShayina. I-SiC technical ceramic: Ubulukhuni bukaMoh buyi-9 (ubulukhuni bukaMoh obuyi-13), bunokumelana okuhle kakhulu nokuguguleka nokugqwala, ukumelana okuhle kakhulu - ukumelana nokugqwala kanye nokulwa nokubola. Impilo yesevisi yomkhiqizo we-SiC ide ngokuphindwe ka-4 kuya ku-5 kune-92% ye-alumina material. I-MOR ye-RBSiC iphindwe ka-5 kuya ku-7 kune-SNBSC, ingasetshenziswa ezimweni eziyinkimbinkimbi kakhulu. Inqubo yokucaphuna iyashesha, ukulethwa kunjengoba kuthenjisiwe futhi ikhwalithi ayilingani. Sihlala siphikelela ekuphonseni inselelo imigomo yethu futhi sibuyisela izinhliziyo zethu emphakathini.