Ityhubhu ye-silicon carbide ekhazimlayo

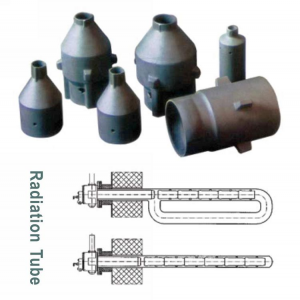

Iimveliso ze-silicon carbidezezona fanitshala zifanelekileyo ze-oven kwii-tunnel kilns, ii-shuttle kilns, ii-roller of hearth kilns njengeetyhubhu zomlilo.

Ngobushushu obuphezulu, ukupholisa okuhle, okukhawulezayo ekuchaseni ubushushu, ukumelana ne-oxidation, ukumelana nokutshayiswa kobushushu, ubomi obude.

Iimbonakalo:

• Ukonga amandla okugqwesileyo.

• Ubunzima obuphantsi kunye nomthwalo ophezulu.

• Ukumelana kakuhle nokugqwetheka kobushushu obuphezulu.

• Ukuqhuba okuphezulu kobushushu

• Imodulus yoMntwana oMkhulu

• I-coefficient yokwandisa ubushushu ephantsi

• Ubulukhuni obuphezulu kakhulu

• Ukumelana nokunxila

Isicelo:

• izixhobo zococeko

• Izinto zokuthambisa ifenitshala yesitovu

• amashishini eephaneli zeglasi

• Iibheringi ezityibilikayo

• ukudutyulwa kwetafile nge-glost.

• Izitshintshi zobushushu

• Izitshisi

• Izixhobo zokunxiba (izikhokelo zemisonto)

Ii-nozzles ze-RBSiC(SiSiC) zisetyenziselwa iinkqubo zobushushu obuphezulu zee-tunnel kilns, ii-shuttle kilns kunye nezinye ezininzi

ezinye ii-oven zemizi-mveliso. Ii-RBSiC(SiSiC)cross beams zinamandla aphezulu kwaye akukho zinguqunguquko nokuba kubushushu obuphezulu kakhulu.

Inkcazo

| Iipropati | Iiyunithi | Izinto zeSilicon Carbide | ||||||

| Uhlobo | I-SiC | I-SiSiC | I-NSiC | I-RSiC | ||||

| Ukwakheka kweekhemikhali | I-SiC% | 89 | 87 | 92 | 70 | 99 | ||

| I-SiO2 % | 5 | 6 | - | I-Si3N4 28 | - | |||

| I-Al2O3% | 1.0 | 2.0 | - | - | - | |||

| Ubude obukhulu | g/cm3 | 2.85 | 2.8 | 3.01 | 2.8 | 2.75 | ||

| Ukuvuleka okubonakalayo | % | 12 | 14 | 0.1 | 12 | 14 | ||

| MOR@20℃ | I-MPa | 50 | 48 | 260 | 180 | 100 | ||

| MOR@1300℃ | I-MPa | 58 | 56 | 280 | 185 | 120 | ||

| I-CTE@20℃-1000℃ | 10-6K-1 | 4.8 | 4.2 | 4.5 | 4.7 | 4.6 | ||

| I-CCS | I-MPa | 100 | 90 | 900 | 500 | 300 | ||

| Ukumelana noxinzelelo olushushu | ★ | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★★ | ||

Ii-nozzles/ii-beams/ii-roller ze-RBSiC(SiSiC) zisetyenziselwa iinkqubo zolwakhiwo lomthwalo kwii-tunnel kilns, ii-shuttle kilns kunye nezinye ezininzi.

ezinye ii-oven zemizi-mveliso. Ii-RBSiC(SiSiC)cross beams zinamandla aphezulu kwaye akukho zinguqunguquko nokuba kubushushu obuphezulu kakhulu.

Kwaye nemiqadi ibonisa ubomi obude bokusebenza. Imiqadi yeyona fenitshala ye-oven efanelekileyo kakhulu kwimpahla yococeko kunye nokusetyenziswa kwe-porcelain yombane. I-RBSiC (SiSiC) inomoya oshushu ogqwesileyo, ngoko ke iyafumaneka ukonga amandla ngobunzima obuncinci bemoto ye-oven.

Ukupakishwa kunye nokuThunyelwa

Iziqwenga ezili-1.50 kwibhokisi yomthi (ivalwe ngokupheleleyo, ikhuselekile kwaye ikhuselekile)

2.800kg ~ 1000kg /ibhokisi yomthi.

3. Ukhuseleko lokungqubana olufana nebhodi yefoam

Iphaneli edibeneyo yomthi enezintlu ezi-4.3, eqinileyo, enganyangekiyo, enganyangekiyo

Iinkcukacha zokuthumela

1. Uthutho lweemoto zobungcali ukuya kwiindawo ezahlukeneyo zaseTshayina, emva koko zilayishwe yinkampani yothutho yobungcali.

2.Zombini i-FOB kunye ne-CIF zinokusetyenziswa ngendlela eguquguqukayo.

3. Uthutho lolwandle olukhuphisanayo kunye nexesha elifutshane lokuhamba.

I-Shandong Zhongpeng Special Ceramics Co., Ltd yenye yezona zisombululo zinkulu zezinto ezintsha ze-silicon carbide ceramic eTshayina. I-SiC technical ceramic: Ubunzima bukaMoh buyi-9 (Ubunzima bukaMoh obuyi-13), bunokumelana okuhle nokukhukuliseka kunye nokugqwala, ukukrala okugqwesileyo - ukumelana nokubola kunye nokuchasana ne-oxidation. Ubomi benkonzo yemveliso yeSiC bubude obuphindwe ka-4 ukuya ku-5 kune-92% ye-alumina material. I-MOR ye-RBSiC iphindwe ka-5 ukuya ku-7 kune-SNBSC, ingasetyenziselwa iimilo ezinzima ngakumbi. Inkqubo yokucaphula iyakhawuleza, ukuhanjiswa kunjengoko kuthembisiwe kwaye umgangatho awulingani. Sihlala siqhubeka nokuchasa iinjongo zethu kwaye sibuyisela iintliziyo zethu kuluntu.