I-silicon carbide i-Sagger ne-Crucible

Lo mkhiqizo ulungele kakhulu i-oven yezimboni, i-sintering, i-smelting futhi usebenza kuzo zonke izinhlobo zemikhiqizo. Emkhakheni wezimboni zamakhemikhali, uphethiloli kanye nokuvikelwa kwemvelo ngezinhlelo zokusebenza eziningi.

1) Ukuqina kokushaqeka kokushisa

2) ukumelana nokugqwala kwamakhemikhali

3) Ukushisa okuphezulu nokukhuthazela (kufika ku-1650°

4) Ukumelana nokugqokwa/ukugqwala/ukubola

5) Ukusebenza kahle kwamandla omshini

6) Ukuhlanza noma ukuqopha izindawo ezingaphansi eziqine kakhulu

7) Isetshenziselwa ukugaya, ukugoqa, nokusika ngesaha kanye nokuqhuma okunamandla

| Ukwakheka Kwamakhemikhali SIC >= | % | 90 | |

| Izinga lokushisa eliphezulu lesevisi. | ºC | 1400 | |

| Ukungavuvukali >= | SK | 39 | |

| 2kg/cm2 Ukuqina kokukhanya ngaphansi komthwalo T2 >= | ºC | 1790 | |

| Impahla yefiziksi | I-Modulus ye-Rupturt ekushiseni kwegumbi >= | Amakhilogremu/cm2 | 500 |

| I-Modulus Yokuqhekeka ku-1400ºC >= | Amakhilogremu/cm2 | 550 | |

| Amandla okucindezela >= | Amakhilogremu/cm2 | 1300 | |

| Ukwanda Kokushisa ku-1000ºC | % | 0.42-0.48 | |

| Ukuvuleka Okubonakalayo | % | ≤20 | |

| Ubuningi obukhulu | g/cm3 | 2.55-2.7 | |

| Ukushisa Okushisayo ku-1000ºC | I-Kcal/m.hr.ºC | 13.5-14.5 | |

Incazelo:

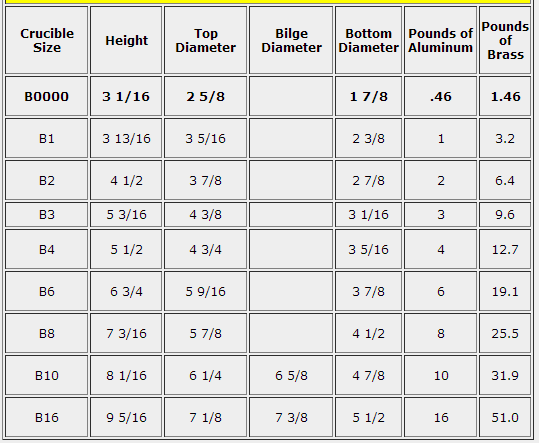

I-crucible iyimbiza ye-ceramic esetshenziselwa ukubamba insimbi ukuze incibilikiswe esithandweni. Lena i-crucible yekhwalithi ephezulu, yezinga lezimboni esetshenziswa imboni yezingcezu zezentengiselwano.

Lokho Okukwenzayo:

Kudingeka i-crucible ukuze imelane namazinga okushisa aphezulu atholakala ezinsimbini ezincibilikayo. Izinto ezincibilikayo kumele zibe nephuzu lokuncibilika eliphakeme kakhulu kunelensimbi encibilikayo futhi kumele zibe namandla amahle ngisho noma zishisa kakhulu.

Kungenzeka ukusebenzisa insimbi eqoshiwe eyenziwe ekhaya ukuncibilikisa izinsimbi ezifana ne-zinc ne-aluminium, ngoba lezi zinsimbi ziyancibilika ekushiseni okungaphansi kakhulu kwensimbi. Kodwa-ke, ukukala (ukuqhekeka) kobuso bangaphakathi bensimbi eqoshiwe kuyinkinga. Lesi sikali singangcolisa ukuncibilika futhi sinciphise izindonga eziqoshiwe ngokushesha. Izikalo zensimbi zizosebenza uma usaqala futhi ungakhathazeki ngokubhekana nokukala.

Izinto ezivamile zokungaguquguquki ezisetshenziswa ekwakheni izinto zokubethela yi-clay-graphite, kanye ne-carbon bonded silicon-carbide. Lezi zinto zingamelana namazinga okushisa aphezulu kakhulu emsebenzini ojwayelekile wokwakha insimbi. I-silicon carbide inenzuzo eyengeziwe yokuba yinto eqinile kakhulu.

Izitsha zethu zobumba ze-Clay Graphite Bilge Shape zilinganiselwe ku-2750 °F (1510 °C). Zizophatha i-zinc, i-aluminium, ithusi/ithusi, isiliva kanye ne-alloys yegolide. Umenzi uthi zingasetshenziswa ensimbini ephothiwe. Kwenziwe e-United States!

Izimo Ezibangwayo:

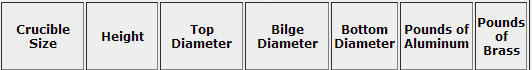

I-crucible enomumo we-bilge (“B” Shape) ibunjwe njengebhakede lewayini. Ubukhulu “be-bilge” buwububanzi be-crucible endaweni yayo ebanzi kakhulu. Uma kungekho ububanzi be-bilge obubonisiwe, khona-ke ububanzi obuphezulu buwububanzi obukhulu.

Umthetho wesithupha uthi i-# ye-crucible "bilge" inikeza amandla ayo okusebenza acishe abe ngamakhilogremu e-aluminium. Uma usebenzisa ithusi noma ithusi, sebenzisa i-crucible ephindwe kathathu kune-crucible #. Isibonelo, i-crucible engu-#10 ingaphatha cishe amakhilogremu angu-10 e-aluminium kanye namakhilogremu angu-30 ethusi.

Izitsha zethu ezibizwa ngokuthi “B” zivame ukusetshenziswa ngabantu abathanda ukuzilibazisa kanye nabantu abavame ukudubula. Lezi ziyizitsha ezisezingeni eliphezulu nezihlala isikhathi eside ezithengiswayo.

Hlola amathebula angezansi ukuthola usayizi ofanele umsebenzi wakho.

Indlela Yokusebenzisa:

Zonke izinto zokubopha kufanele ziphathwe ngezibambo ezifakwa kahle (ithuluzi lokuphakamisa). Izibambo ezingalungile zingabangela umonakalo noma ukwehluleka ngokuphelele kwesibambo ngesikhathi esibi kakhulu.

Idiski yekhadibhodi ingafakwa phakathi kwe-crucible nesisekelo sesithando ngaphambi kokushisa. Lokhu kuzosha, kushiye ungqimba lwekhabhoni phakathi futhi kuvimbele i-crucible ukuthi inamathele phansi kwesithando. Ukwembozwa kwe-Plumbago (Carbon Black) kwenza into efanayo.

Kungcono ukusebenzisa i-crucible ehlukile kuhlobo ngalunye lwensimbi ukuze ugweme ukungcola. Qiniseka futhi ukuthi uthulula yonke i-crucible ngemuva kokusebenzisa. Insimbi eshiywe ukuze iqine ku-crucible ingakhula ekufudumaleni kabusha futhi iyibhubhise.

Sicela ulinganisele ama-crucible amasha noma lawo abekade egcinwe. Shisisa i-crucible engenalutho amahora ama-2 ku-220 F (104 C). (Sebenzisa umoya owanele. Ama-crucible amasha azobhema njengoba i-glaze iqala ukuqina.) Bese ushisa i-crucible engenalutho ibe bomvu. Vumela i-crucible iphole kuze kufike ekushiseni kwegumbi esithandweni ngaphambi kokusebenzisa. Le nqubo kufanele ilandelwe YONKE ama-crucible amasha kanye nanoma iyiphi i-crucible okungenzeka ukuthi ivele ezimweni ezimanzi lapho igcinwe khona.

Gcina zonke izitsha zokubhaka endaweni eyomile. Umswakama ungabangela ukuthi isitsha sokubhaka siqhekeke lapho sifudumala. Uma sesigcinwe isikhathi eside kungcono ukuphinda ukufudumala.

Izitsha zokumboza ze-silicon carbide ziyindlela engenakwenzeka kakhulu yokumunca amanzi agcinwe futhi ngokuvamile azidingi ukushiswa ngaphambi kokusetshenziswa. Kungumqondo omuhle ukuvuthela isitsha sokumboza esisha sibe bomvu ngaphambi kokusetshenziswa kwaso kokuqala ukuze kuqhunyiswe futhi kuqiniswe izimbozo zasefektri kanye nezihlanganisi.

Izinto kufanele zifakwe esitsheni esivuthayo kalula. UNGALOKOTHI “upakishe” isitsha esivuthayo, njengoba izinto zizokhula ekushiseni futhi zingaqhekeza i-ceramic. Uma le nto isincibilikile yaba “isithende”, faka ngokucophelela izinto ezengeziwe echibini ukuze zincibilike. (ISEXWAYISO: Uma kukhona umswakama ezintweni ezintsha kuzovela UKUQHUBEKA komusi). Nalapha futhi, ungapakishi insimbi ngokuqinile. Qhubeka ufaka izinto ezincibilikile kuze kube yilapho inani elidingekayo selincibilikile.

ISEXWAYISO!!!: Izitsha Zokubumba ziyingozi. Ukuncibilikisa insimbi esitsheni sokubumba kuyingozi. Ukuthela insimbi ezikhumbeni kuyingozi. Izitsha Zokubumba zingase zingasebenzi ngaphandle kwesixwayiso. Izitsha Zokubumba zingaqukatha amaphutha afihliwe ezintweni zokwakha kanye nokukhiqiza okungaholela ekwehlulekeni, ekulimaleni kwempahla, ekulimaleni komuntu, ekulimaleni kwababukele kanye nokulahlekelwa yimpilo.

Ibhlokhi Lesisekelo Esiqinile

Incazelo:

I-BCS Ibhlogo lesisekelo liyisisekelo sokushisa okuphezulu esisetshenziselwa ukuphakamisa i-crucible endaweni yokushisa yesithando somlilo.

Lokho Okukwenzayo:

Ibhlogo lesisekelo livame ukusetshenziswa esithandweni somlilo esisebenza ngegesi ukuphakamisa i-crucible phezulu ukuze ilangabi lesishisi lingaqhumi ngqo odongeni oluncane lwe-crucible. Uma ilangabi lesishisi livunyelwe ukuthi lishaye ngqo i-crucible lingabangela ukuguguleka kodonga lwe-crucible ngaleyo ndlela linciphise isikhathi salo sokuphila. Indlela efanele yokuvimbela lokhu ukusebenzisa ibhlogo lesisekelo ukuphakamisa i-crucible endaweni ye-burner.

Ukuphakamisa i-crucible kuvumela nokuthi ibe “sendaweni yokushisa” yesithando somlilo. Nakuba ilangabi lesishisi lingena emzimbeni wesithando somlilo phansi, indawo eshisayo kakhulu isukela phakathi kuya phezulu. Kukulesi sifunda lapho izindonga zesithando somlilo zifudunyezwa khona yigesi ejikelezayo ngempumelelo enkulu. Ukuba nezinhlangothi zesithando somlilo kulesi sifunda kukhuthaza ukushisa okungcono kakhulu okuvela emsinga wegesi ovunguzayo kanye nemisebe yokushisa yezindonga zangaphakathi zesithando somlilo esikhanyayo.

Indlela Yokusebenzisa:

Ibhlogo eliyisisekelo kufanele libe lide ngokwanele ukuze ilangabi lesishisi lihambisane nengxenye ephezulu yebhloko. Kulungile uma ingxenye ephezulu yebhloko iphakeme kune-inlet yesishisi. Okungadingeki ukuthi ilangabi lishaye izinhlangothi ezincane ze-crucible. Kuyamukeleka futhi uma ilangabi lishaya ingxenye engezansi ejiyile ye-crucible njengoba le ngxenye ingenakuguguleka ngenxa yegesi.

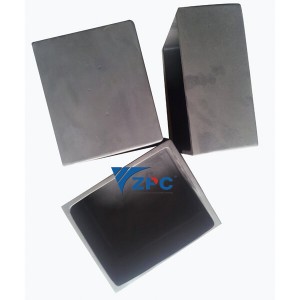

Izikebhe kanye nama-Saggers:

I-Shandong Zhongpeng Special Ceramics Co., Ltd ingenye yezixazululo ezinkulu zezinto ezintsha ze-silicon carbide ceramic eShayina. I-SiC technical ceramic: Ubulukhuni bukaMoh buyi-9 (ubulukhuni bukaMoh obuyi-13), bunokumelana okuhle kakhulu nokuguguleka nokugqwala, ukumelana okuhle kakhulu - ukumelana nokugqwala kanye nokulwa nokubola. Impilo yesevisi yomkhiqizo we-SiC ide ngokuphindwe ka-4 kuya ku-5 kune-92% ye-alumina material. I-MOR ye-RBSiC iphindwe ka-5 kuya ku-7 kune-SNBSC, ingasetshenziswa ezimweni eziyinkimbinkimbi kakhulu. Inqubo yokucaphuna iyashesha, ukulethwa kunjengoba kuthenjisiwe futhi ikhwalithi ayilingani. Sihlala siphikelela ekuphonseni inselelo imigomo yethu futhi sibuyisela izinhliziyo zethu emphakathini.