Roala silicon carbide e hanelang le phaephe ea ceramic ea alumina

![]()

Carbide ea silicon e kopantsoeng le karabelo (SiSiC kapa RBSIC) ke thepa e loketseng e hanelang ho tsofala, e leng

e loketse haholo bakeng sa ho khohlela ho matla, likaroloana tse mahoashe, ho hlopha, mahloriso, ho felloa ke metsi 'meleng le

mesebetsi e meng. E sebelisoa haholo indastering ea merafo, indastering ea tšepe, indastering ea ts'ebetso ea likorale, lik'hemik'hale

indasteri, indasteri ea ho etsa lintho tse tala, ho tiisa mechine, kalafo ea lehlabathe le reflector holim'a metsi jj.

Ka lebaka la ho thatafala ho hoholo le ho hanyetsa ho khopisang, e ka sireletsa karolo eo ho hlokahalang ho e roala ka katleho.

tšireletso, e le ho lelefatsa bophelo ba tšebeletso ea lisebelisoa.

Mokhoa oa ho khetholla le ho fumana lipoleiti, lithaele, li-liners tsa boleng bo holimo tse sa keneng ka har'a silicon carbide?

Lithaele, li-liners, le liphaephe tse sa tsofaleng tsa silicon carbide li ntse li sebelisoa haholo indastering ea merafo.

Lintlha tse latelang ke tsa bohlokoa ho uena:

1. Foromo le mokhoa:

Ho na le mefuta e mengata ea SiC 'marakeng. Re sebelisa mekhoa ea 'nete ea Sejeremane. Litekong tsa laboratori tsa boemo bo holimo, tahlehelo ea khoholeho ea sehlahisoa sa rona e ka fihla ho 0.85 ± 0.01;

2. Boima:

Lithaele tsa SiC li hlahisoa ka ZPC: boima bo bocha ba Mohs: 14.55 ± 4.5 (MOR, psi)

3. Boima:

Bongata ba bongata ba thaele ea ZPC SiC bo ka ba 3.03+0.05.

4. Boholo le Bokaholimo:

Lithaele tsa SiC tse hlahisitsoeng ka ZPC ntle le mapetso le masoba, tse nang le libaka tse bataletseng le mathoko le likhutlo tse sa senyehang.

5. Thepa ea ka hare:

Li-liner/lithaele tse sa senyeheng tsa silicon carbide li na le thepa e ntle le e lekanang ea kahare le kantle.

If any questions, please feel free to contact us: info@rbsic-sisic.com

■Litlhaloso:

| Ntho | Yuniti | Lintlha |

| Mocheso oa ts'ebeliso | ℃ | 1380℃ |

| Botenya | G/cm3 | >3.02 |

| Maro a bulehileng | % | 0.1 |

| Matla a ho kobeha -A | Mpa | 250 (20℃) |

| Matla a ho kobeha -B | MPa | 280 (1200℃) |

| Modulus ea ho tenyetseha-A | GPa | 330(20℃) |

| Modulus ea ho tenyetseha -B | GPa | 300 (1200℃) |

| Ho khanna ha mocheso | W/mk | 45 (1200℃) |

| Tekanyo e sebetsang ea katoloso ea mocheso | K-1 ×10-6 | 4.5 |

| Ho tiea | / | 13 |

| Alkaline e sa keneng ka asiti | / | e babatsehang |

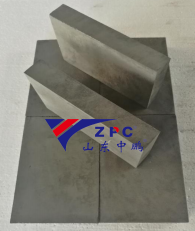

■Sebopeho le boholo bo fumanehang:

Botenya: ho tloha ho 6mm ho isa ho 25mm

Sebopeho se Tloaelehileng: Poleiti ea SISIC, Phaephe ea SISIC, Lihokelo tse Tharo tsa SiSiC, Setsoe sa SISIC, Leholiotsoana la Khoune ea SISIC.

Tlhokomeliso: Boholo le sebopeho tse ling lia fumaneha ha ho kopuoa.

■Sephutheloana:

Ka lebokoseng la lebokose, le pakiloe ka har'a pallet ea lehong e fumisitsoeng ka oli e boima ba 20-24MT/20′FCL.

■Melemo ea bohlokoa:

1. Ho hanyetsa ho tsofala ho babatsehang, ho hanyetsa tšusumetso le ho hanyetsa ho bola;

2. Ho batalla haholo le ho hanyetsa mocheso hantle ho fihlela ho 1350℃

3. Ho kenya habonolo;

4. Bophelo ba tšebeletso bo bolelele (bo feta ba alumina ceramic ka makhetlo a 7 le ka makhetlo a 10 ho feta ba

polyurethane

Paterone ea ho senyeha ha khutlo Ho senyeha ho thellang ha khutlo e tlase

Ha phallo ea thepa e khorofo e otla bokaholimo ba ho tsofala ka sekhutlo se sa tebang kapa e feta ka lehlakoreng le leng, mofuta oa ho tsofala ho hlahang khohlanong o bitsoa ho thella ha ho thella.

Li-ceramic tsa silicon carbide tse tsoetseng pele li fana ka ho hanyetsa ho tsofala le ho hanyetsa ho tsofala ha lithaele tsa ceramic le lesela. Lihlahisoa tsena li pakiloe hore lia tsofala ha lisebelisoa ts'ebetsong ea ho tsamaisa, ho sebetsana le ho boloka. Lithaele tsa rona li ka hlahisoa ka botenya ho tloha ho 8 ho isa ho 45mm. Ho bohlokoa ho netefatsa hore u ka fumana lihlahisoa tse hlokahalang. SiSiC: Bothata ba Moh ke 9.5 (Bothata ba Moh bo bocha ke 13), bo nang le ho hanyetsa ho tsofala le ho tsofala, ho taboha ho hoholo - ho hanyetsa le ho thibela oxidation. E matla ka makhetlo a 4 ho isa ho a 5 ho feta nitride bonded silicon carbide. Bophelo ba ts'ebeletso bo bolelele ka makhetlo a 5 ho isa ho a 7 ho feta thepa ea alumina. MOR ea RBSiC e feta ka makhetlo a 5 ho isa ho a 7 ho feta SNBSC, e ka sebelisoa bakeng sa libopeho tse rarahaneng haholoanyane. Lesela la ceramic le hanyetsang ho tsofala lea tsamaisa ho ntlafatsa ts'ebetso ea tlhahiso, bokhoni ba ho sebetsa, phokotso ea litšenyehelo tsa tlhokomelo le phaello e eketsehileng.

Diserame tse nepahetseng di na le tsebo ya dintho tse bonahalang, boiphihlelo bo sebedisitsweng le bokgoni ba boenjiniere. Sena se ka netefatsa ka katleho hore ditharollo tse ntle di fanwa ho bareki ba rona. Dithaele tsa ceramic tsa silicon carbide le lesela la ho kenya di atisa ho sebediswa ditshebedisong tse kang diholiotsoana, di-tube, di-chute, di-hopper, diphaephe, mabanta a ho tsamaisa le ditsamaiso tsa tlhahiso. Tsamaisong, ho na le dintho tse tsamayang tse thellang hodima bokahodimo. Ha ntho e thella hodima thepa, e senya dikarolo butle-butle ho fihlela ho se na letho le setseng. Dibakeng tse nang le ho tsofala haholo, sena se ka etsahala kgafetsa mme sa baka mathata a mangata a turang. Sebopeho se seholo se bolokwa ka ho sebedisa thepa e thata haholo, jwalo ka diserame tsa silicon carbide le diserame tsa alumina e le lesela la sehlabelo. Ka nako e ts'oanang, diserame tsa silicon carbide di ka mamella ho tsofala nako e telele pele di hloka ho nkelwa sebaka, bophelo ba tshebeletso ya ceramic ya silicon carbide bo bolelele ka makgetlo a 5 ho isa ho a 7 ho feta thepa ya alumina.

Lithaele tsa Ceramic tse sa Khaotseng ho Roala tsa Silicon Carbide le Thepa ea ho Roala:

E hanela lik'hemik'hale

E sireletsang mocheso ka motlakase

E hanela khoholeho ea metjhini le ho khoholeha

E ka nkeloa sebaka

Melemo ea Lithaele le Li-Lining tse Hanelang ho Tloha ka Ceramic:

E ka sebelisoa moo ho hlokahalang mamello e tiileng kapa masela a masesaane

E ka sebelisoa ho tsosolosa libaka tse seng li ntse li tsofala

E ka sebelisoa ka mekhoa e mengata ea ho hokela joalo ka ho tjheseletsa le likhomaretsi

E etselitsoe lits'ebetso tse ikhethileng

E hanela mafome haholo

Tharollo ea ho fokotsa ho robeha ha bobebe

E sireletsa likarolo tse tsamaeang tse ka bang kotsing ea ho senyeha haholo

E tšoarella nako e telele haholo ebile e sebetsa hantle ho feta litharollo tsa ho fokotsa ho tsofala

Mocheso o phahameng ka ho fetisisa oa tšebeliso o fihlang ho 1380°C

1、 Setsi sa tšepe le tšepe: 1, mochini o kopanyang meropa o nang le lesela la ho tjhesa 2, rabara ea letsopa e phuthetsoeng ka meropa 3, impeller ea fene 4, sesebelisoa sa ho fepa ka disc, sejana sa thepa e omileng 5, sehokelo sa coke, setshelo sa converter, setshelo sa coke, setshelo sa lerole la sefefo.

2、 Setsi sa motlakase: 1. Sehokelo sa mochini oa bolo, volute ea mochini, sehokelo sa mochini oa lebelo le mahareng, setsoe sa phaephe ea phofo, sekotlo sa lerōle la sefefo, silo, hopper 2, hopper ea mashala, karohano ea phofo e mahoashe le e ntle, sehokelo sa mochini oa mashala, hopper e tsamaisang mashala 3, hopper ea mashala ea ho tšoara borokho, hopper ea mashala e bohareng ea sehokelo sa mashala, phallo ea mochini oa bolo, ho kena le ho tsoa ha karohano ea phofo e mahoashe le e ntle, volute ea mosi oa phofo 4 Mefuta e fapaneng ea li-burners tse tobileng, tse teteaneng le tse fokolang tse sa tsofaleng mochesong o phahameng bakeng sa li-boiler tse chesitsoeng ka mashala; liphaephe le litsoe tsa ceramic tse hanelang ho tsofala haholo, li-burners tsa ceramic, lifensetere tsa ceramic, li-impeller tsa ceramic, li-valve tsa ceramic, jj.; likarolo tse fapaneng tse hanelang ho tsofala tse kang libolo tsa ho sila, matsoho a roller, li-disc tsa ho sila, lithaele tsa disc, masale a ho sila, libolo tsa nozzle le likarolo tse ling tse hanelang ho tsofala bakeng sa li-mill tsa mashala tse lebelo le mahareng; liphaephe, damper e hanelang ho tsofala le lifensetere tsa litlhaloso tse fapaneng bakeng sa litsamaiso tsa ho sila le ho tlosa molora; Libolo Mefuta eohle ea tšilo e na le (kapa che) lithaele tsa bolt lining, poleiti ea lining, phaephe e potolohang, lesale la gear, bolo ea tšepe e nang le chromium e tlaase, jj.; lebili le otlang, poleiti e otlang, sehokelo sa tšireletso, lihlomo, karohano, phaephe ea khase ea flue ea ontong e nang le mocheso o phahameng, jj. bakeng sa fene ea mashala; lisebelisoa tse hlokahalang bakeng sa mefuta e fapaneng ea mechini e pshatlang.

3, Selei sa pampiri: 1. Phaephe ea mashala e silafalitsoeng

Lihlahisoa le lits'ebeletso tse ka sehloohong: 1. Liphaephe tsa ceramic tse hanang ho tsofala tsa indasteri: mefuta eohle ea ceramic e hanang ho tsofala le e hanang mocheso o phahameng e koahetsoeng ka mashala a silafalitsoeng, li-tailings, slurry ea slag, phaephe ea lipalangoang ea slurry, setsoe, setsoe, setofo sa mashala se silafalitsoeng, sehokelo sa mochini oa mashala, karohano ea leholiotsoana le lesesaane la phofo e mahoashe le e ntle, chute, hopper, bin ea polokelo, moqomo oa tšepe oa karohano ea merafo; 2. Fene ea ceramic e hanang ho roala: mefuta eohle ea impeller ea fene e hanang mocheso o phahameng, e hanang ho tsofala, e thibelang ho tsofala le volute, ho kenyeletsoa fene ea centrifugal, fene ea phallo ea axial, lehare le sa sisinyeheng, impeller ea fene e ka fetoloang lehare le tsamaeang, fene ea ho hula, e ntšang mosi oa phofo, fene ea sintering, fene ea karohano ea phofo, fene ea ho tlosa lerōle, fene ea hlooho ea ontong le ea mohatla oa ontong, jj; 3. Pompo ea lesela la ceramic e hanang ho roala le valve: lesela la ceramic, impeller ea pompo, khetla, baffle, setsoe sa phaephe, valve ea ho tlosa molora oa pneumatic le phetisetso ea khase le lisebelisoa tsa slurry e fapaneng, slurry ea slag, seretse, li-tailings le litsamaiso tse ling tsa lipalangoang. 4. Liaparo tsa ceramic tse hanang ho roala: mefuta eohle ea liaparo tsa ceramic tse hanang ho roala le tse hanang mocheso o phahameng le mastic li sebelisoa bakeng sa fan volute, phala ea setsoe, sehokelo sa sile, phala ea karohano e mahoashe le e tšesaane, chute, hopper le valve. 5. Lisebelisoa tsa karohano ea makenete tse hanang ho roala: likarolo tsa phallo ea lisebelisoa tse fapaneng tsa ts'ebetso ea liminerale tse omileng le tse metsi, ho kenyeletsoa teramo ea karohano ea makenete, mokoti o ka tlase, chute, phaephe, lipompo tse fapaneng tsa seretse, pompo ea slurry volute, impeller, le phaephe ea ho tsamaisa. 6. Theknoloji ea ho fafatsa holim'a metsi: ho sebelisoa phepelo ea motlakase ea morao-rao ea machaba ea inverter pulse arc le sethunya sa ho fafatsa sa arc se lebelo le phahameng, lisebelisoa tse fapaneng tsa tšepe tse hanang ho roala le tse thibelang ho roala li fafatsoa holim'a substrate ea tšepe ho etsa lera le sireletsang ho roala le ho thibela ho roala. E ka fana ka tšireletso e sebetsang bakeng sa mefuta eohle ea ho roala hoa matla a mahareng.

Shandong Zhongpeng ZPC ceramics ke kgwebo e ikgethileng tlhahisong ya di-ceramic tsa diindasteri, haholo-holo e sebetsanang le R&D le tlhahiso ya di-ceramic tsa silicon carbide. Re ka sebetsana le dihlahiswa tsa ceramic ho ya ka ditshwantsho tsa hao, re ikgethile ka tlhahiso ya boholo bo boholo, molamu wa ceramic o nepahetseng haholo, phaephe ya ceramic, lesale la ceramic, poleiti ya ceramic, flange ya ceramic, nozzle ya ceramic, le dikarolo tse ikgethileng tse hanelang ho robeha ka boholo bo boholo.

Shandong Zhongpeng Special Ceramics Co., Ltd ke e 'ngoe ea litharollo tse kholo ka ho fetisisa tsa thepa e ncha ea silicon carbide Chaena. SiC technical ceramic: Bothata ba Moh ke 9 (Bothata ba Moh bo bocha ke 13), bo nang le khanyetso e ntle khahlanong le khoholeho le mafome, khanyetso e ntle - khanyetso le anti-oxidation. Bophelo ba tšebeletso ea sehlahisoa sa SiC bo bolelele ka makhetlo a 4 ho isa ho a 5 ho feta thepa ea alumina ea 92%. MOR ea RBSiC e feta ka makhetlo a 5 ho isa ho a 7 ho feta SNBSC, e ka sebelisoa bakeng sa libopeho tse rarahaneng haholoanyane. Ts'ebetso ea khotheishene e potlakile, phano e etsoa joalo ka ha e tšepisitsoe 'me boleng ha bo fete letho. Kamehla re phehella ho phephetsa lipheo tsa rona 'me re khutlisetsa lipelo tsa rona sechabeng.