Mugadziri/fekitori weSiC Crucibles neSaggers – SiC Sagger yePowder Sintering

SiC Sagger yeKubvisa Upfu

RBSIC/SISIC crucible ndiro yakadzika ine midziyo yeceramic. Nekuda kwekushanda kwayo kuri nani pane midziyo yegirazi pakupisa, inoshandiswa zvakanaka kana zvinhu zvakasimba zvichipiswa nemoto.

Sagger yakagadzirwa nedhaka risingagadzike rine maitiro akasiyana-siyana edhaka, rakabikwa pakupisa kwakanyanya. Ndiyo imwe yemidziyo yakakosha yemoto wekupisa porcelain. Mhando dzese dzeporcelain dzinofanira kuiswa mumasaggers kutanga dzozoiswa mumoto wekupisa.

ZVINHU ZVINONYANYA KUKOSHA:

| Index | RSiC | NSiC | RBSiC | SiC |

| Kuwanda kwehuwandu (g/cm3) | 2.65-2.75 | 2.75-2.85 | ≥3.02 | 2.8 |

| SiC(%) | ≥99 | ≥75 | 83.66 | 90 |

| Si3N4(%) | 0 | ≥23 | 0 | 0 |

| Si(%) | 0 | 0 | 15.65 | 9 |

| Kuyerera kwemvura (%) | 15-18 | 10-12 | 0.1 | 7-8 |

| Simba rekukotama (MPa) | 80-100(20℃) | 160-180(20℃) | 250(20℃) | 500(20℃) |

| Simba rekukotama (MPa) | 90-110 (1200℃) | 170-180 (1200℃) | 280 (1200℃) | 550 (1200℃) |

| Simba rekukotama (MPa) | 90-120 (1350℃) | 170-190 (1350℃) | - | - |

| Modulus ye elasticity (GPa) | 300(20℃) | 580(20℃) | 330(20℃) | 200 |

| Modulus ye elasticity (GPa) | - | - | 300 (1200℃) | - |

| Kufambisa kwemafuta (wm-1.k-1) | 36.6 (1200℃) | 19.6 (1200℃) | 45 (1200℃) | 13.5-14.5 (1000℃) |

| Kuwedzerwa kwemafuta kwakaenzana (K-1×10-6) | 4.69 | 4.7 | 4.5 | 3 |

| Kuomarara | - | - | 13 | - |

| Kupisa kwakanyanya kushanda (℃) | 1620 (okisijeni) | 1450 | 1380 | 1300 |

FEKTORI:

Nezvedu:

Tiri kambani inonyanya kugadzira RBSIC/SISIC Silicon Infiltrated Silicon Carbide Products.

- Maitiro Ekugadzira Nyanzvi

- Zvinhu Zvisina Kugadzirwa Zvemhando Yepamusoro Zvinobva Kunyika

- Sisitimu Yekutarisira Kugadzira Yakazara

Katalogu:

Zvakanakira:

- Simba guru uye kuomarara kwakanyanya

- Kudzivirira kupisa kwakanyanya uye kudzivirira kupisa kwakanyanya

- Kugona kubereka kwakanaka kwazvo

- Kuramba kupisa kwakanyanya uye kutonhora.

- Kudzivirira kupisa kwakanyanya

- Kuramba ngura uye kuramba Oxidation

- Kudzivirira acid ne alkali

- Kuramba kupfeka & kufambisa zvakanaka kwekupisa

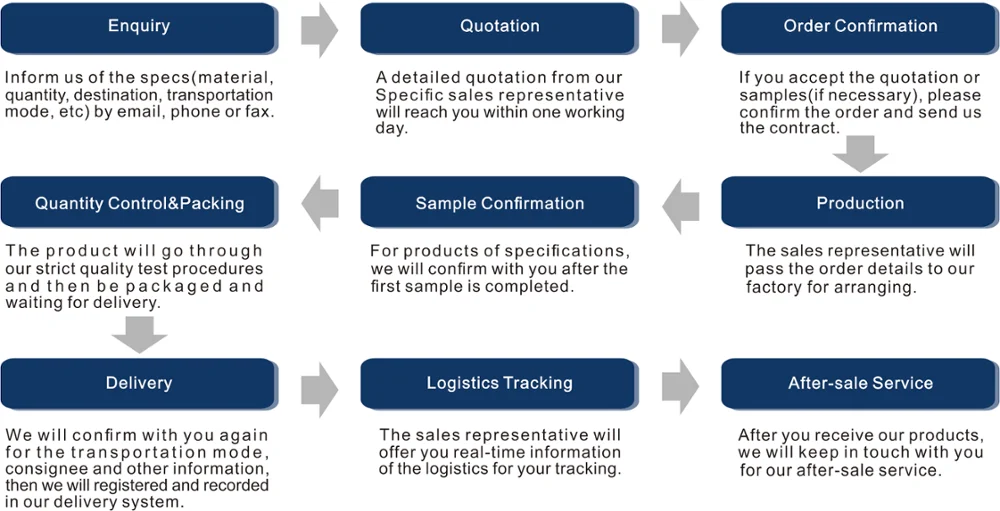

MAITIRO EKUTONGA:

MAITIRO EKUGADZIRA:

Zvigadziko zvesimbi zvesilicon carbide ceramics zvinogona kushandiswa pakugadzira hupfu hwakasiyana-siyana, kunyungudutsa simbi, nezvimwewo muminda yesimbi, indasitiri yemakemikari, magirazi nezvimwewo. Shandong Zhongpeng yakazvipira kutsvagisa nekugadzira, kugadzira nekutengesa zvigadzirwa zvesilicon carbide zvine simba guru, zvigadzirwa zvikuru zvinoti reaction sintered silicon carbide ceramic beams, roller bars, fire nozzles, cold air ducts, sheds, enamel, enamel, thermocouple protection Tube, heat exchange tube, radiant tube inner tube, radiant tube outer tube, desulfurization nozzle, cantilever paddle, atmosphere furnace tube, jecha blasting nozzle, bushing, seal uye akasiyana-siyana high temperature, wear and corrosion resistant silicon carbide ceramic shaped Piece, nezvimwewo, reaction sintered silicon carbide ceramic products dzine simba guru, high hardness, wear resistant, high tembiricha resistant, corrosion resistant, thermal shock resistant uye thermal conductivity, resistant to quenching uye fast heat and high tembiricha creep resistant, inoshandiswa zvakanyanya mumauto, aerospace, nuclear power, liquid crystal and metallurgy, chemical, machinery, mota, bepa, mishonga nedzimwe nzvimbo, zvigadzirwa zvinotumirwa kuUnited States, Germany, Japan, South Korea, United Arab Emirates, South Africa, Taiwan nedzimwe nyika dzinopfuura makumi mana nenzvimbo.

Kuomarara kwesilicon carbide (SiSiC): Moh's hardness ndeye 9.5, ine simba guru rekukurwa nekuora, inodzivirira kukwesha uye inodzivirira oxidation. Yakasimba ka4 kusvika ka5 kupfuura nitride bonded silicon carbide. Hupenyu hwekushanda hwakareba ka7 kusvika ka10 kupfuura alumina material. MOR yeRBSiC yakapetwa ka5 kusvika ka7 kupfuura SNBSC, inogona kushandiswa kune mamwe maumbirwo akaomarara.

KUPAKISHA:

Shandong Zhongpeng Special Ceramics Co., Ltd ndeimwe yemhando huru dzesilicon carbide ceramic itsva muChina. SiC technical ceramic: Kuomarara kwaMoh kwa9 (Kuomarara kwaNew Moh kwa13), nekusimba kwakanaka pakukukurwa nekuora, kusimba kwakanaka - kusimba uye kudzivirira oxidation. Hupenyu hwebasa rechigadzirwa cheSiC hwakareba ka4 kusvika ka5 kupfuura 92% alumina material. MOR yeRBSiC yakapetwa ka5 kusvika ka7 kupfuura SNBSC, inogona kushandiswa kune mamwe maumbirwo akaomarara. Maitiro ekukosha kwemashoko anokurumidza, kuendesa kwacho kwakaitwa sezvakavimbiswa uye mhando yacho haina kukosha. Tinogara tichiramba tichipikisa zvinangwa zvedu uye tinopa moyo yedu kunharaunda.