Onye nrụpụta/ụlọ ọrụ mmepụta ihe SiC Crucibles na Saggers – SiC Sagger maka ntụ ntụ Sintering

SiC Sagger maka ntụ ntụ Sintering

RBSIC/SISIC Crucible bụ efere miri emi nke e ji ihe seramiiki mee. N'ihi na ọ na-arụ ọrụ nke ọma karịa ihe iko na-eguzogide okpomọkụ, a na-eji ya nke ọma mgbe ọkụ na-ekpo ọkụ ihe siri ike.

A na-eji apịtị na-anaghị agbaze agbaze nke nwere nkọwa dị iche iche nke ngwa agha ahụ, a na-esi ya n'ọkụ dị elu. Ọ bụ otu n'ime arịa ụlọ dị mkpa maka ọkụ poselin. A ga-ebu ụzọ tinye ụdị poselin niile n'ime saggers wee tinye ya n'ime ọkụ maka ịcha.

Nkọwapụta:

| Ndepụta Ndekọ | RSiC | NSiC | RBSiC | SiC |

| Njupụta dị ukwuu (g/cm3) | 2.65-2.75 | 2.75-2.85 | ≥3.02 | 2.8 |

| SiC(%) | ≥99 | ≥75 | 83.66 | 90 |

| Si3N4(%) | 0 | ≥23 | 0 | 0 |

| Si(%) | 0 | 0 | 15.65 | 9 |

| Ntụpọ (%) | 15-18 | 10-12 | 0.1 | 7-8 |

| Ike ịgbagọ (MPa) | 80-100(20℃) | 160-180(20℃) | 250 (20℃) | 500 (20℃) |

| Ike ịgbagọ (MPa) | 90-110 (1200℃) | 170-180 (1200℃) | 280 (1200℃) | 550 (1200℃) |

| Ike ịgbagọ (MPa) | 90-120 (1350℃) | 170-190 (1350℃) | - | - |

| Modulu nke elasticity (GPa) | 300 (20℃) | 580(20℃) | 330 (20℃) | 200 |

| Modulu nke elasticity (GPa) | - | - | 300 (1200℃) | - |

| Ọkwa okpomọkụ (wm-1.k-1) | 36.6 (1200℃) | 19.6 (1200℃) | 45 (1200℃) | 13.5-14.5 (1000℃) |

| Ọnụọgụ nke mgbasawanye okpomọkụ (K-1 × 10-6) | 4.69 | 4.7 | 4.5 | 3 |

| Isi ike | - | - | 13 | - |

| Oke okpomọkụ ọrụ (℃) | 1620 (oksid) | 1450 | 1380 | 1300 |

Ụlọ ọrụ mmepụta ihe:

Gbasara anyị:

Anyị bụ ụlọ ọrụ pụrụ iche na mmepụta nke RBSIC/SISIC Silicon Infiltrated Silicon Carbide Products.

- Usoro Mmepụta Ọkachamara

- Ihe ndị dị elu e si mba ọzọ bubata

- Sistemụ Njikwa Mmepụta zuru oke

KATALỌGỤ:

Uru:

- Ike dị elu na oke ike

- Nguzogide okpomọkụ dị elu na oke nguzogide okpomọkụ dị mma

- Ikike ibu dị mma nke ukwuu

- Mgbochi oke okpomọkụ na oyi.

- Nguzogide okpomọkụ dị elu

- Nguzogide corrosion na Nguzogide Oxidation

- Mgbochi acid na alkali

- Nguzogide iyi na ezigbo njikwa okpomọkụ

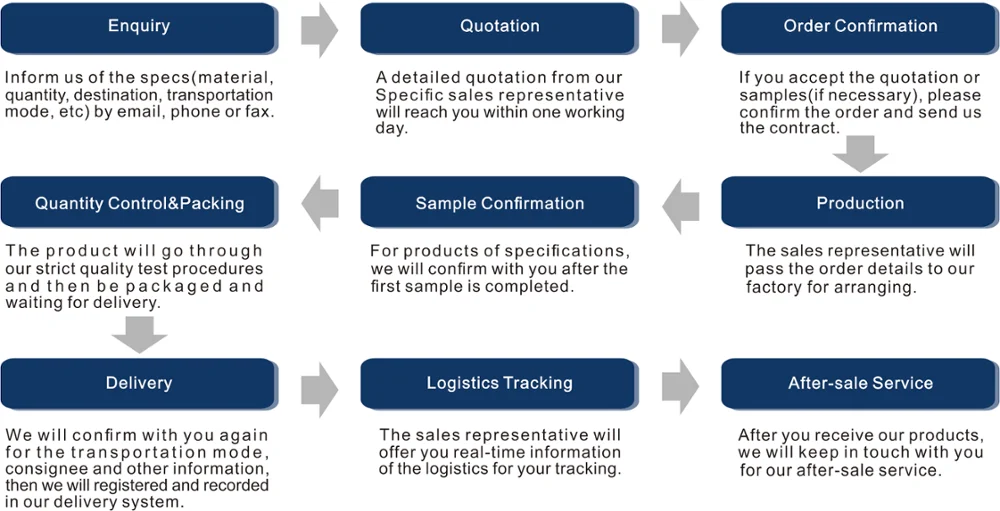

Usoro Inye Iwu:

Usoro Mmepụta:

Enwere ike iji ihe mkpuchi seramiiki silicon carbide na saggers mee ihe maka nsị ntụ ntụ dị iche iche, ịgbaze ígwè, wdg. n'ọhịa nke igwe, ụlọ ọrụ kemịkalụ, iko na ihe ndị yiri ya. Shandong Zhongpeng na-agba mbọ ime nnyocha na mmepe, mmepụta na ire ngwaahịa silicon carbide dị elu, ngwaahịa ndị bụ isi bụ ihe ndị e ji seramiiki silicon carbide mee, ihe ndị e ji atụgharị ihe, ihe ndị e ji ọkụ mee, ihe ndị e ji ekpuchi ikuku oyi, ihe ndị e ji ekpuchi ikuku, enamel, enamel, ihe ndị e ji echebe thermocouple, ihe ndị e ji echekwa okpomọkụ, ihe ndị e ji emegharị tube dị n'ime, ihe ndị e ji emegharị tube dị n'èzí, ihe ndị e ji emechi ihe ...

Carbide silicon nke ejiri ihe megharịa ahụ (SiSiC): Ike Moh bụ 9.5, ọ na-eguzogide mbuze na ire ere nke ọma, ọ na-eguzogidekwa nbibi na mgbochi oxidation nke ọma. Ọ siri ike karịa carbide silicon nke ejiri nitride jikọta ugboro 4 ruo 5. Ndụ ọrụ ya dị okpukpu 7 ruo 10 karịa ihe alumina. MOR nke RBSiC dị okpukpu 5 ruo 7 karịa nke SNBSC, enwere ike iji ya maka ọdịdị ndị ka mgbagwoju anya.

NKWEKỌTA:

Shandong Zhongpeng Special Ceramics Co., Ltd bụ otu n'ime ihe ngwọta ọhụrụ seramiiki silicon carbide kachasị ukwuu na China. Seramiiki teknụzụ SiC: Ike Moh bụ 9 (ike Moh ọhụrụ bụ 13), yana ezigbo iguzogide mbuze na nchara, ezigbo nbibi - iguzogide na mgbochi oxidation. Ndụ ọrụ nke ngwaahịa SiC dị okpukpu 4 ruo 5 karịa ihe alumina 92%. MOR nke RBSiC bụ ugboro 5 ruo 7 nke SNBSC, enwere ike iji ya maka ụdị ndị ka mgbagwoju anya. Usoro nhota dị ngwa, nnyefe dị ka ekwere nkwa na ịdị mma ya adịghị elu. Anyị na-anọgide na-agba mbọ mgbe niile n'ịma aka ebumnuche anyị ma na-enye obi anyị nye ọha mmadụ.