Produsen Nozzle Semprotan Penyerap SiC kanthi Kualitas Apik

Shandong Zhongpeng Special Ceramics Co., Ltd minangka produsen Nozzle Semprotan Penyerap paling gedhe ing China, Asia. Nozzle Semprotan FGD digawe kanthi nganyari adhedhasar teknologi Jerman. Nozzle iki nduweni arah ganda, diameter gedhe, laju aliran gedhe lan ningkatake efisiensi desulfurisasi. Minangka pemasok nozzle profesional kanggo sistem desulfurisasi gas buang, kita duwe pengalaman sing sugih ing aplikasi lan pamisahan semprotan. Kita bisa nyedhiyakake macem-macem produk kanthi Performa sing dhuwur lan dipercaya lan dhukungan teknis sing kuwat uga layanan sawise sing sampurna.

Nozel desulfurisasi RBSC (SiSiC) minangka bagean penting saka sistem desulfurisasi gas buang ing pembangkit listrik tenaga termal lan boiler gedhe. Nozel iki akeh dipasang ing sistem desulfurisasi gas buang ing akeh pembangkit listrik tenaga termal lan boiler gedhe.

Ing abad kaping 21, industri ing saindenging jagad bakal ngadhepi tuntutan sing saya tambah kanggo operasi sing luwih resik lan luwih efisien.

Perusahaan ZPC setya nindakake tugas kita kanggo nglindhungi lingkungan. ZPC spesialisasine ing desain nozzle semprotan lan inovasi teknologi kanggo industri kontrol polusi. Liwat efisiensi lan keandalan nozzle semprotan sing luwih dhuwur, emisi beracun sing luwih murah menyang udara lan banyu saiki bisa digayuh. Desain nozzle BETE sing unggul nduweni fitur penyumbatan nozzle sing luwih sithik, distribusi pola semprotan sing luwih apik, umur nozzle sing luwih dawa, lan keandalan lan efisiensi sing tambah.

Nozzle sing efisien banget iki ngasilake diameter tetesan paling cilik ing tekanan paling endhek sing nyebabake kebutuhan daya kanggo mompa luwih murah.

Rong bolongan, siji nozzle semprotan, menyang nozzle liyane, supaya saben nozzle semprotan bisa nyebar kanthi rata, nanging isih bisa dirancang kanggo fluktuasi aliran cairan ing rong bolongan sing beda, kayata: 80% mudhun, 20% disuntikake munggah.

Nozzle Semprotan SiSiC (RBSiC) utamane digunakake ing pembangkit listrik utawa boiler skala gedhe.

Nozzle penyemprotan pusaran ganda nduweni rong ruang pusaran sing mbukak menyang sisih sing ngelawan lan ing saben kasus disusun ing sisih masing-masing bidang tengah longitudinal sing ngluwihi saluran aliran mlebu lan luwih becik dirancang kanthi simetris pangilon gegayutan karo sumbu tengah saluran aliran mlebu. Desain iki nggampangake medium mlebu tanpa ana penyempitan penampang menyang rong ruang pusaran lan metu kanthi pusaran sing beda ing arah sing ngelawan.

Fitur

1. Toleransi suhu dhuwur

2. Tahan korosi

3. Kekuwatan lentur sing dhuwur

4. Resistensi oksidasi.

Nozel pemotong linier arus eddy SiSiC, Nozel Semprotan Silikon Karbida Ikatan Reaksi Digunakake ing Pembangkit Listrik, nozel turbulensi didol, nozel tangensial SiSiC

Nozel semprotan SiC:

1. Resistensi oksidasi

2. Tahan korosi

3. Toleransi suhu dhuwur

4. Kekuwatan lentur

Shandong Zhongpeng Special Ceramics Co., Ltd:

• Garis nozel spiral paling amba kalebu desain tahan mampet sing luwih apik, sudut sing luwih amba, lan macem-macem aliran.

• Macem-macem desain nozzle standar: saluran mlebu tangensial, nozzle disk pusaran, lan nozzle kipas, uga nozzle atomisasi udara aliran rendah lan dhuwur kanggo aplikasi penggosokan quench lan garing.

• Kemampuan sing ora ana tandhingane kanggo ngrancang, nggawe, lan ngirim nozzle khusus. Kita kerja bareng karo sampeyan kanggo nyukupi peraturan pemerintah sing paling angel. Kita bisa nyukupi syarat khusus sampeyan, mbantu sampeyan entuk kinerja sistem sing optimal.

Katrangan Singkat babagan Zona Scrubber FGD

Nyegerake:

Ing bagean scrubber iki, gas cerobong panas dikurangi suhune sadurunge mlebu ing pre-scrubber utawa absorber. Iki bakal nglindhungi komponen sensitif panas ing absorber lan nyuda volume gas, saengga nambah wektu tinggal ing absorber.

Pra-Scrubber:

Bagean iki digunakake kanggo mbusak partikulat, klorida, utawa loro-lorone saka gas cerobong asap.

Penyerap:

Iki biasane menara semprotan mbukak sing nggawa bubur scrubber menyang kontak karo gas cerobong asap, saengga reaksi kimia sing ngiket SO2 kedadeyan ing bah.

pengepakan:

Sawetara menara duwe bagean pengepakan. Ing bagean iki, bubur disebar ing pengepakan sing longgar utawa terstruktur supaya permukaan sing kena gas buang saya tambah akeh.

Baki Gelembung:

Sawetara menara duwé pelat bolong ing ndhuwur bagean penyerap. Bubur diendapké kanthi rata ing pelat iki, sing nyeimbangaké aliran gas lan nyedhiyakake area permukaan sing kontak karo gas.

Penghilang Kabut:

Kabeh sistem FGD teles ngasilake persentase tartamtu saka tetesan sing alus banget sing digawa dening gerakan gas buang menyang lawang metu menara. Eliminator kabut yaiku serangkaian baling-baling sing ruwet sing njebak lan ngembun tetesan, saengga bisa dibalekake menyang sistem. Kanggo njaga efisiensi mbusak tetesan sing dhuwur, baling-baling eliminator kabut kudu diresiki kanthi periodik.

Kerucut berongga Seri TH Pusaran Tangensial

Desain

• Seri nozel sudut tengen nggunakake saluran mlebu tangensial kanggo ngasilake pusaran

• tahan mampet: nozzle ora duwe bagean njero

• konstruksi: pengecoran siji-potong

• sambungan: flens utawa wadon, ulir NPT utawa BSP

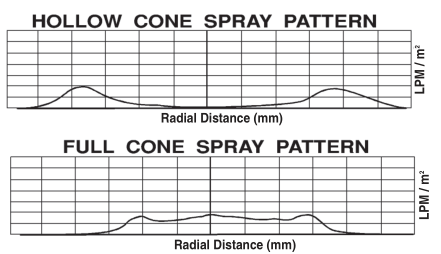

Karakteristik semprotan

• Distribusi semprotan sing rata banget

• Pola semprotan: kerucut kothong

• Sudut semprotan: 70° nganti 120°

• Laju aliran: 5 nganti 1500 gpm (15,3 nganti 2230 l/menit)

Kanthi ukuran khusus kanggo nyukupi spesifikasi sing tepat

Nozzle Spiral Kerucut Lengkap

Seri ST, STXP, TF, TFXP

Desain

• Nozzle spiral asli

• Kacepetan debit dhuwur

• Efisiensi energi sing dhuwur

• tahan mampet: konstruksi siji-sijine tanpa bagean njero

• konstruksi: pengecoran siji, loro utawa telung potongan

• sambungan: Utas NPT utawa BSP sambungan lanang standar, utas wadon lan sambungan flens kasedhiya kanthi pesenan khusus

Karakteristik semprotan

• Atomisasi alus

• Pola semprotan: kerucut lengkap lan kopong

• Laju aliran: 0,5 nganti 3320 gpm (2,26 nganti 10700 l/menit) kasedhiya laju aliran sing luwih dhuwur

Bahan: Silikon Karbida Ikatan Reaksi (RBSC)

Ukuran: 0,75 inci, 1,2 inci, 1,5 inci, 2 inci, 2,5 inci, 3 inci, 3,5 inci, 4 inci, 4,5 inci lan miturut kabutuhan khusus sampeyan.

Shandong Zhongpeng Special Ceramics Co., Ltd minangka salah sawijining solusi bahan anyar keramik silikon karbida paling gedhe ing China. Keramik teknis SiC: Kekerasan Moh yaiku 9 (kekerasan Moh Anyar yaiku 13), kanthi resistensi sing apik banget marang erosi lan korosi, resistensi abrasi sing apik banget lan anti-oksidasi. Umur layanan produk SiC 4 nganti 5 kali luwih dawa tinimbang bahan alumina 92%. MOR RBSiC yaiku 5 nganti 7 kali lipat saka SNBSC, bisa digunakake kanggo bentuk sing luwih kompleks. Proses kutipan cepet, pangiriman kaya sing dijanjekake lan kualitas ora ana tandhingane. Kita tansah terus nantang tujuan kita lan menehi ati kita bali menyang masyarakat.