Nozzle Sprial Kerucut Lengkap RBSC

Prinsip kerja nozzle spiral silikon karbida

Nalika cairan kanthi tekanan lan kecepatan tartamtu mili saka ndhuwur mudhun menyang nozzle spiral RBSC/SiSiC, cairan ing sisih njaba nabrak helicoid kanthi sudut tartamtu ing nozzle. Iki bisa ngganti arah semprotan adoh saka nozzle. Sudut sing kalebu (sudut heliks) antarane streamline permukaan kerucut lapisan sing beda-beda lan tengah nozzle mboko sithik suda.Iki konduktif kanggo nambah area sing nutupi cairan sing metu kanthi efektif.

Nozzle spiral RBSC/SiSiC umume digunakake kanggo desulfurisasi lan dedusting bledug. Nozzle iki bisa ngasilake bentuk kerucut kothong lan kerucut padat kanthi sudut spiral saka 60 nganti 170 derajat. Kanthi ngethok lan tabrakan karo awak spiral sing terus luwih cilik, cairan kasebut bakal malih dadi cairan cilik menyang rongga nozzle. Desain saluran saka impor menyang metu ora dihambat dening bilah lan pandhuan apa wae. Ing kasus aliran sing padha, diameter maksimum nozzle spiral sing ora diblokir luwih saka 2 kali lipat saka nozzle konvensional. Iki bisa nyuda kedadeyan alangan kanthi maksimal.

Silikon Karbida minangka bahan sing entheng, atos banget, lan tahan korosi sing ndadekake calon sing kuwat kanggo aplikasi aus ing lingkungan sing paling atos. Silikon Karbida uga nawakake sifat liyane sing dikarepake kayata konduktivitas termal sing apik banget lan modulus enom sing dhuwur.

- Aplikasi

- Onderdil peralatan proses semikonduktor

- Onderdil mesin industri umum

- Bagian tahan abrasi

Nozzle desulfurisasi silikon karbida sinter reaksi vakum minangka bagean penting saka set lengkap peralatan desulfurisasi lan penghilang bledug kanggo pembangkit listrik termal, boiler gedhe. Produk iki nduweni sifat sing apik banget kayata kekuatan dhuwur, kekerasan dhuwur, tahan korosi sing kuwat, keausan sing abot lan tahan suhu dhuwur. Atomizer desulfurisasi silikon karbida sinter reaksi sing diprodhuksi dening perusahaan kita nduweni distribusi tetesan semprotan sing seragam, saluran aliran sing ora alangan, lan ngganti produk impor kanthi lengkap, ngisi kekosongan domestik. Saiki, ana telung seri pusaran, spiral lan kolom cair, sing wis diterapake ing piranti desulfurisasi lan penghilang bledug ing akeh pembangkit listrik termal lan boiler gedhe, lan ana ing kondisi kerja sing apik.

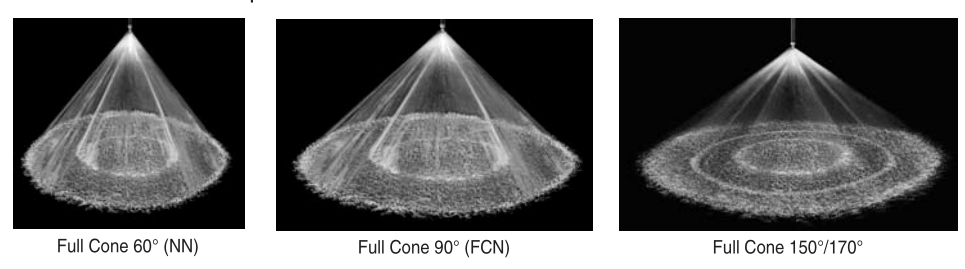

Efek semprotan saka nozel spiral kerucut padat

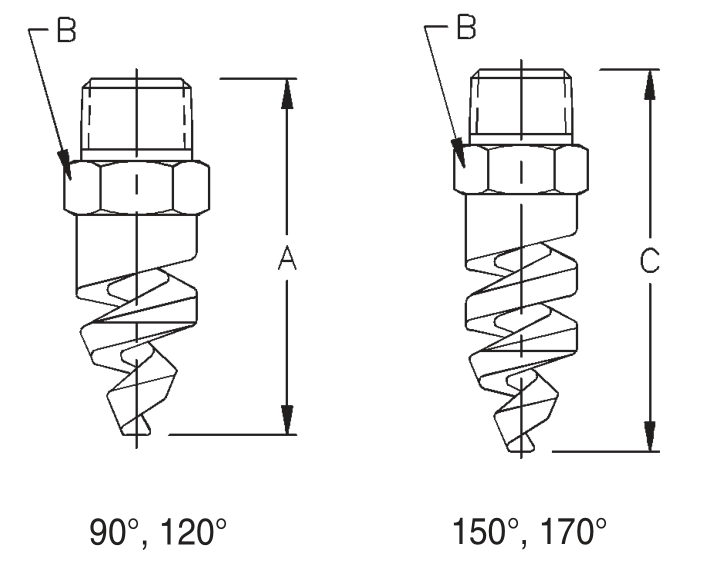

Laju lan Dimensi Aliran Kerucut Lengkap

Kerucut Lengkap, 60° (NN), 90° (FCN utawa FFCN), 120° (FC utawa FFC), 150°, lan 170° Sudut Semprotan, Ukuran Pipa 1/8″ nganti 4″

Sudut semprotan:

Shandong Zhongpeng Special Ceramics Co., Ltd minangka salah sawijining solusi bahan anyar keramik silikon karbida paling gedhe ing China. Keramik teknis SiC: Kekerasan Moh yaiku 9 (kekerasan Moh Anyar yaiku 13), kanthi resistensi sing apik banget marang erosi lan korosi, resistensi abrasi sing apik banget lan anti-oksidasi. Umur layanan produk SiC 4 nganti 5 kali luwih dawa tinimbang bahan alumina 92%. MOR RBSiC yaiku 5 nganti 7 kali lipat saka SNBSC, bisa digunakake kanggo bentuk sing luwih kompleks. Proses kutipan cepet, pangiriman kaya sing dijanjekake lan kualitas ora ana tandhingane. Kita tansah terus nantang tujuan kita lan menehi ati kita bali menyang masyarakat.