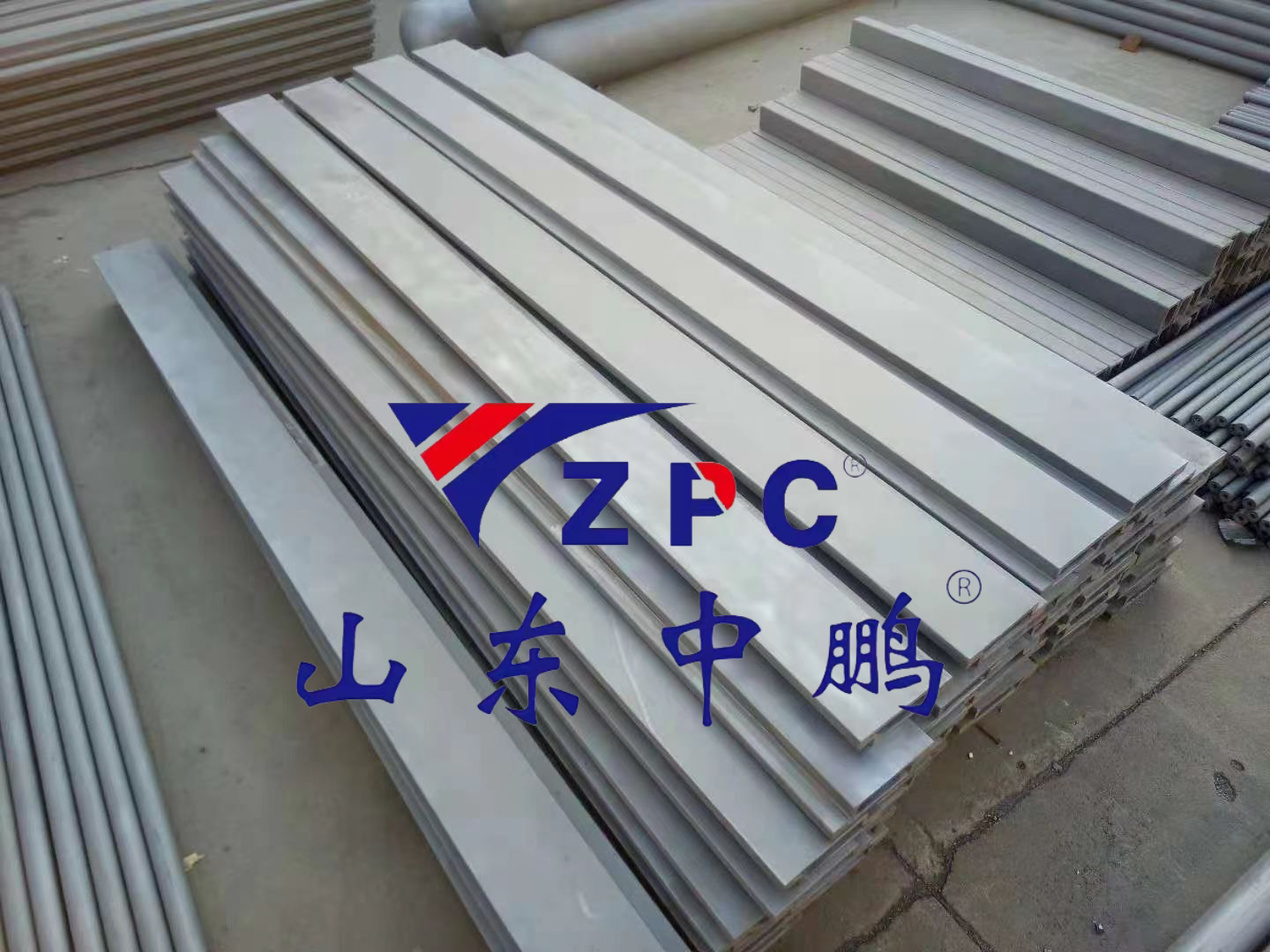

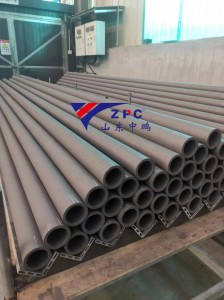

Imisebe ye-silicon carbide

Amarola e-ceramic e-silicon carbide (R-SiC) asebenza nge-reaction-sinteredKuvele njengezingxenye ezibalulekile ezinhlelweni zesimanje zokucubungula ukushisa, ikakhulukazi ezivelele ekukhiqizeni ibhethri le-lithium, ekukhiqizweni kwe-ceramics okuthuthukisiwe, kanye nokushisa izinto ezisebenza ngogesi ngokunemba. Lawa ma-roller akhethekile achaza kabusha amazinga okusebenza ezithandweni zezimboni ezishisa kakhulu ngokubhekana nezinselele ezibalulekile ekuzinzeni kokushisa kanye nokuqina kwemishini.

Ukusebenza Kokushisa Okungalingani

Aklanyelwe ukusebenza ngokuqhubekayo ku-1450-1600°C – ephakeme kakhulu kunama-roller e-alumina avamile – ama-roller e-R-SiC agcina ukunemba okulinganayo ngisho nangaphansi kokujikeleza kokushisa okukhulu. Isakhiwo sawo esiyingqayizivele senza:

• Ukufana kokudlulisa ukushisa okusheshayo (±5°C kubude be-roller)

• Ukumelana nemijikelezo yokushaqeka kokushisa engaphezu kwe-100 (1400°C ↔ izinga lokushisa legumbi)

• Akukho ukuguquguquka kokuqhekeka emazingeni okushisa aphezulu aqhubekayo

Izinhlelo Zokusebenza Ezibalulekile Zichazwe Kabusha

1. Ukukhiqizwa Kwebhethri Le-Lithium

- Ukuqondanisa okunembile kokuthungwa kwezinto ze-electrode

- Ukuphathwa kwama-cathode e-NMC/LFP okungenakho ukungcola

- Ukusebenza okuzinzile ekunciphiseni umoya

2. Ukucubungula Okuthuthukisiwe Kwe-Ceramics

- Usekelo olungenama-warp lwamathayili amakhulu (kufika ku-1.5×3m)

- Ukulawulwa kwesivinini okuqhubekayo emigqeni yokucwebezelisa yezimpahla zangasese

- Ukuphela kobuso obungaphawuli (Ra <0.8μm)

3. Ukukhiqiza Izinto Ezine-Magnetic

- Ukujikeleza okungenazo izithiyo zokushisa kwe-ferrite okuqondiswe ngqo

- Ukungasebenzi kahle kwamakhemikhali ezindaweni ezicebile nge-hydrogen

Izinzuzo Zokusebenza

Umthamo Womthwalo: Isekela isisindo esikhulu esingu-3-5 × ngobude beyunithi uma kuqhathaniswa nama-roller e-alloy ensimbi

Ukumelana Nokuguquka: Igcina ukuqondeka okungaphansi kuka-0.05mm/m ngemva kwamahora okusebenza ayi-10,000

Ukusebenza Kahle Kwamandla: Ukusetshenziswa kwamandla kwesithando kuncishiswe ngo-18-22% ngokusatshalaliswa kokushisa okuhle

Ukuhambisana Nezimboni Ezihlukahlukene: Kungashintshwa kuma-shuttle kilns, ama-roller hearths anezingqimba eziningi, kanye nama-hybrid tunnel furnaces

Ukusimama Komnotho

Nakuba kudinga ukutshalwa kwezimali kokuqala okuphezulu ngo-30-40% kunama-roller avamile, izixazululo ze-R-SiC zibonisa:

- Izikhawu zesevisi ezinde ngo-70% (iminyaka engu-5-7 uma kuqhathaniswa neminyaka engu-2-3)

- Ukuphinda kusetshenziswe kabusha okungu-90% ngezinqubo zokuvuselela ukushisa

- Izindleko zokulungisa eziphansi ngo-60% ezivela ezindaweni ezingagugi

Umklamo Olungele Ikusasa

Ama-roller e-R-SiC esimanje manje ahlanganisa:

- Imigoqo yokulandelela eqoshwe nge-laser yemigqa yokukhiqiza ezenzakalelayo

- I-porosity engenziwa ngezifiso yokungena komkhathi othize

- Izinzwa zokushisa ezihlanganisiwe zokusebenza kwe-smart kiln

Lokhu kuthuthuka kobuchwepheshe kubeka ama-rollers e-silicon carbide asebenza ngokusabela njengezingxenye ezibalulekile ezinhlelweni zokushisa zezimboni zesizukulwane esilandelayo, okuvumela abakhiqizi ukuthi bafinyelele ukulawula izinga lokushisa okuqinile, ukuhambisana okuphezulu komkhiqizo, kanye nokusebenza kokukhiqiza okusimeme emikhakheni eminingi yobuchwepheshe obuphezulu.

I-Shandong Zhongpeng Special Ceramics Co., Ltd ingenye yezixazululo ezinkulu zezinto ezintsha ze-silicon carbide ceramic eShayina. I-SiC technical ceramic: Ubulukhuni bukaMoh buyi-9 (ubulukhuni bukaMoh obuyi-13), bunokumelana okuhle kakhulu nokuguguleka nokugqwala, ukumelana okuhle kakhulu - ukumelana nokugqwala kanye nokulwa nokubola. Impilo yesevisi yomkhiqizo we-SiC ide ngokuphindwe ka-4 kuya ku-5 kune-92% ye-alumina material. I-MOR ye-RBSiC iphindwe ka-5 kuya ku-7 kune-SNBSC, ingasetshenziswa ezimweni eziyinkimbinkimbi kakhulu. Inqubo yokucaphuna iyashesha, ukulethwa kunjengoba kuthenjisiwe futhi ikhwalithi ayilingani. Sihlala siphikelela ekuphonseni inselelo imigomo yethu futhi sibuyisela izinhliziyo zethu emphakathini.