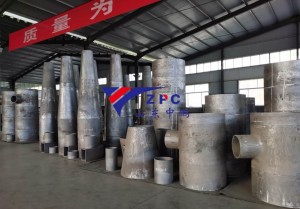

Kwimveliso yemizi-mveliso, imibhobho yokuhambisa ifana nemithambo yegazi, ethwala ukuhamba kwezinto ezifana ne-ore, i-slag, kunye ne-slurry yobushushu obuphezulu. Nangona kunjalo, kwimeko enzima yokuhamba ngesantya esiphezulu, ubushushu obuphezulu kunye noxinzelelo, kunye nokugqwala okunamandla, imibhobho yendabuko idla ngokujongana neengxaki zokuguga ngokukhawuleza, ubomi obufutshane benkonzo, kunye neendleko eziphezulu zokulungisa. Okwangoku, yethuiipayipi ze-silicon carbideyaqala ukusebenza, ngokuzolileyo yaba “ngumlindi wezixhobo” kwishishini, yakha umgca wokhuselo oqinileyo weenkqubo zemibhobho.

1, Izinto ezingundoqo eziqinileyo: izikhuselo zoshishino ezenziwe ngobuchwepheshe

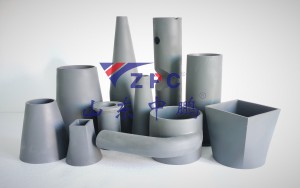

Imfihlo ye-silicon carbide lining ivela kwi-"idayimani emnyama yezimboni" eyenziwe ngokwenziwa - izinto ze-silicon carbide. Ngokusebenzisa inkqubo yokusila yokusabela kobushushu obuphezulu, le nto igcina ubulukhuni obufana nedayimani kunye nokumelana nokugqwala kwe-ceramic. Umphezulu wayo uthambile njengesipili, kodwa inokuhlala izinzile njengelitye xa ilwa ngokusondeleyo namasuntswana abukhali eeminerali; Ijongene namaqondo obushushu ashushu amawaka eedigri okanye ukukhukuliseka okuvela kwii-asidi ezinamandla kunye ne-alkalis, isenokuhlala ingenawo umkrwelo - olu phawu "luthambileyo noluqinileyo" luyenza ikwazi ukumelana neemeko ezahlukeneyo zokusebenza ezinzima.

2, 'Iqhawe Elihlala Lihleli' ezantsi emgodini

Kwindawo yokwemba, umbhobho othwala impahla udlula “kwisivuthuvuthu sesanti negrabile” yonke imihla. Imibhobho yentsimbi yendabuko inokugutywa ngaphakathi kweenyanga, ngelixa imibhobho enee-silicon carbide ifana nesikrweqe – xa i-ore kunye ne-slag zidlula ngesantya esiphezulu, umaleko okhuselayo owahlukileyo wenziwa phezu komphezulu we-lining, nto leyo enciphisa kakhulu i-friction coefficient. Umthengi wethu wenze uthelekiso: emva kokutshintsha i-silicon carbide lining, umbhobho owawufuna ukutshintshwa rhoqo ngoku unobomi benkonzo obongezelelekileyo, unciphisa ixesha lokungasebenzi lokugcinwa ngeeyure ezingama-400 ngonyaka. Olu tshintsho alunciphisi nje iindleko zokugcinwa, kodwa lukwabangela ukuba ukusebenza komgca wemveliso kuchaneke kwaye kuthembeke njengewotshi.

3, Ingcali enobuchule kwizicelo ezinqumla imida

Inqanaba le-silicon carbide lingaphezulu kakhulu kwemigodi:

Isityalo sesamente: Kwinkqubo yokuhambisa i-clinker, siyamelana nempembelelo eqhubekayo yezinto ezishushu kakhulu.

Isityalo seekhemikhali: Imithombo enamandla yokubola ihamba kakuhle kwiindonga zangaphakathi ezithambileyo, ishiya ukukrwela kunye nokuvaleka.

Ishishini lamandla: Kwinkqubo yokuhambisa uthuthu oluhamba ngeempukane, i-lining iyadanisa ngamasuntswana othuthu ahamba ngesantya esiphezulu ngaphandle kokuguguleka.

Kwicandelo lamandla amatsha, qinisekisa ukuba akukho kuthuthwa kongcoliseko lwezixhobo ezicocekileyo kakhulu kwimveliso yezinto zebhetri ye-lithium.

Le nto itshintshe nendlela eyilwe ngayo le zixhobo – njengoko ingaphakathi libonelela ngokhuseleko olufana “nekhaka legolide” kumbhobho, iinjineli ziqalile ukusebenzisa ngesibindi izakhiwo zodonga lwepayipi ezibhityileyo nezikhaphukhaphu.

4, Amandla angabonakaliyo aqhuba ixabiso lexesha elide

Ukukhetha i-silicon carbide lining ngokuyintloko lutyalo-mali oluhlala ixesha elide ekusebenzeni kakuhle kwemveliso. Isenokungabi sesona sixhobo sibalaseleyo kwimveliso, kodwa ivelisa ixabiso ngeendlela ezintathu ngokuthe cwaka:

1. Ubungakanani bexesha: Yandisa umjikelo wokutshintshwa kwemibhobho ukuze wonge iindleko ezibangelwa kukutshintshwa kwezixhobo rhoqo.

2. Ubungakanani bokusetyenziswa kwamandla: I-coefficient ye-friction ephantsi kakhulu igcina amandla ngokufanelekileyo kwinkqubo yokuhambisa.

3. Ubungakanani bokhuseleko: Ukunciphisa kakhulu okanye ukuphelisa iingozi ezibangelwa kukonakala kwemibhobho.

Umthengi wethu wakha wahlekisa wathi, “Ukususela oko kwasetyenziswa i-silicon carbide lining, umbhobho wokuthutha ususiwe 'kuluhlu lwezinto ezisengozini' ukuya 'kwikhathalogu yezinto ezisisigxina'.

Kwiphulo lanamhlanje lokuvelisa ngempumelelo nangokuzinzileyo, ulwelo lwe-silicon carbide luphinda luchaze imigangatho yokuqina kwemibhobho yemizi-mveliso. Isenokungabi nobunzima obufana nentsimbi, kodwa ngamandla etekhnoloji ingqina ukuba ukhuseleko lokwenyani alukho kubungakanani bezinto, kodwa kulawulo oluchanekileyo kwihlabathi le-microscopic.

Ukuba ufuna ukufunda okungakumbi malunga nomgca wepayipi onganyangekiyo we-silicon carbide, nceda undwendwele[Shandong Zhongpeng]Ukuze ufumane iinkcukacha ezithe vetshe ngemveliso, okanye utsalele umnxeba ku-(+86) 15254687377 ukuze wenze idinga lokuxilonga ukusebenza kakuhle kwamandla kumgca wemveliso – masisebenzisane, sifezekise intsebenziswano phakathi kwamaqela omabini, size sibone utshintsho oluthuleyo malunga nokuqina kwemizi-mveliso.

Ixesha leposi: Epreli-03-2025