Nasadka peskovaya-Material- karbid kremniya

Nasadka peskovaya-Material- karbid kremniya

| SiC va SiSiC texnik ma'lumotlari – kremniy karbidi | ||

| Mulklar | SiC (99%) | SiSiC |

| Zichlik (g/sm³) | 3.15 ±0.03 | 3.2 |

| G'ovaklik foizi (sub-mikron) | 3.15 ±0.03 | 0.00% |

| Maksimal harorat (°C) | 410 | 1150°C |

| Bükülme kuchi (MPa) @ RT | 2800 | 800 |

| Weibull moduli | 3970 (560) | 15-30 |

| Elastik modul (GPa) | 4 | 310 |

| Puasson nisbati | 0.21 | 0,27 |

| Qattiqlik HV (0,3) Kg/mm2 | 4×10-6 | 1800-yil |

| Sinishga chidamlilik (MPam1/2) | 120 ta | 5.5 |

| Aşındırıcı aşınma qarshilik parametri | 0.67 | 1110 |

| Issiqlik kengayish koeffitsienti 10-6/C; (RT-1000 C) | 1500 | 3.1 |

| Mulk qiymatlari taxminiy - odatiy hisoblanadi va texnik xususiyatlar sifatida ko'rib chiqilmasligi kerak. | ||

Silikon karbidli keramika (RBSC/SiSiC laynerlari) – YouTube https://www.youtube.com/watch?v=Caqp0Rrfhgo

Izvesten sposob zashchity vnutrenney ra bochey poverxnosti gidrotsiklon fasonnym kamennym litem. Futerovku osushchestvlyayut 1O ukladkoy i zakrepleniem v korpuse gidrotsiklona s pomoshchyu tsementnogo rastvora otdelnyh nabornyx kamneltyx elementov. Nedostatki etoho sposoba vĐ” vysokaya trudoemkost montaj elementov iz-za netochnosti ix geometrik formalari, katta trudnosti demontaja iznoshennoy futerovki. gidrotsiklona, uhudshaet texnologicheskie pokazateli ego raboty, snijaet srok slujby futerovki v tselom.

B mohs, RBSiC keramika prevyshaet 9, kotoryy blizok k tverdosti almazov.srok slujby sic keramika – v 10 dan katta, chem u poliuretanovoy obolochkoy.

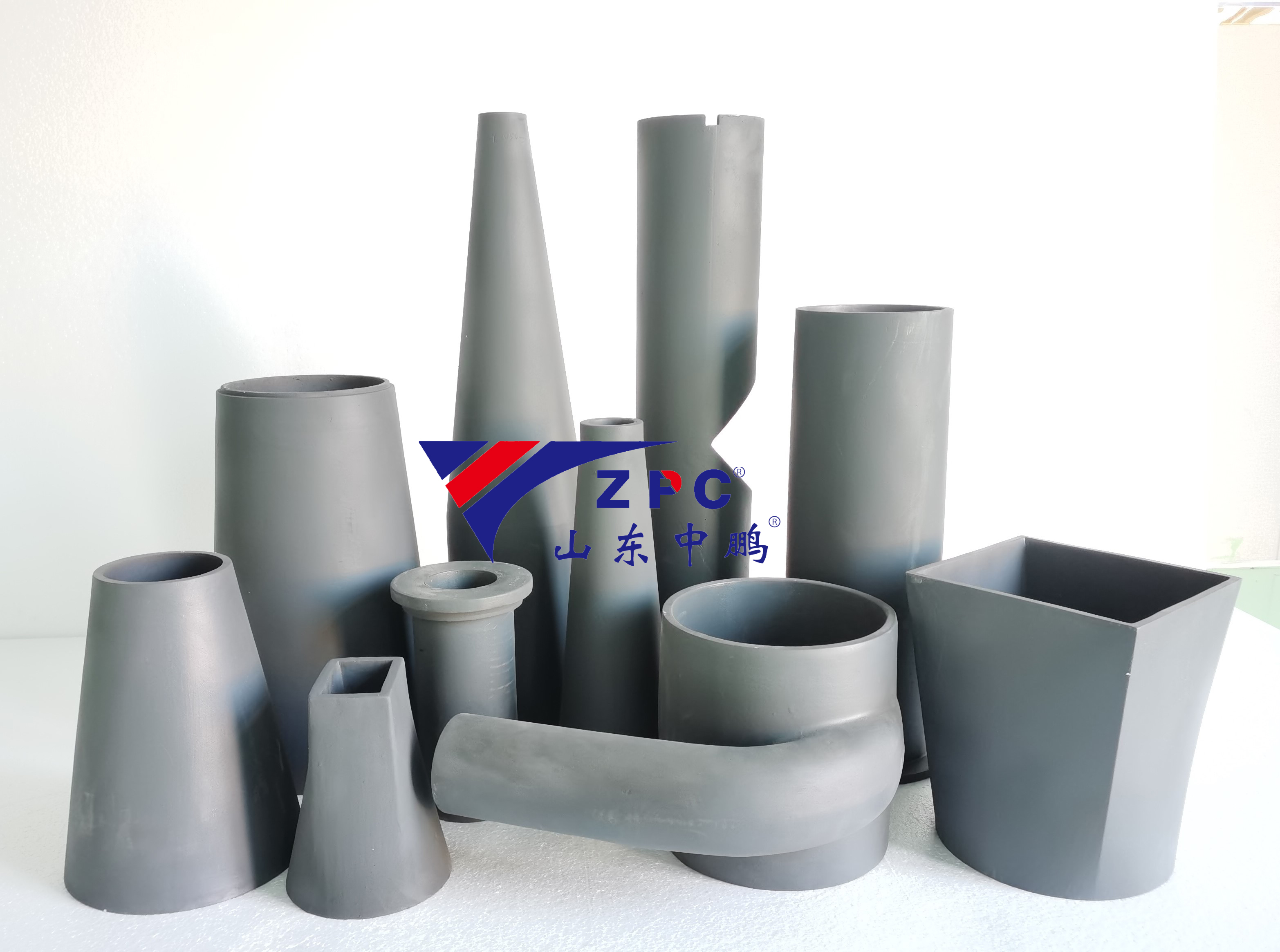

ZPC razrabatyvaet va proizvodit vysokoeffektyvnye tsiklony, gidrotsiklonnye, gidrotsiklonnye vkladyshi va vspomogatelnye komponentlar o'z ichiga o'tkazuvchanlik keramicheskyh materiallardan foydalanish uchun ekstremal abrazivnyh va agressiv sredah.

Prodvinutaya keramika RBSiC s tverdostyu to 3500 Vickers bir necha oddiy materiallardan iborat bo'lib, uni o'z ichiga oladi. Oni znachitelno bolee iznosostoykie, chem nerjaveyushchie stali, ni-tverdye va stellitovye materiallar, traditsionno ispolzuemye pri proizvodstve etix tipov gidrotsiklonov.

Nashi gidrotsiklony prednaznacheny razdeleniya zahvachennyh tverdyx veshchestv iz bolshinstva jidkostey v atmosfernyh va vysokotemperaturnyx abrazivnyh va agressivnyx sredah.

My postavlyaem mno obraztsov peredogogo SiC-keramicheskogo gidrotsiklona uchun nefti, shaxte va dori vositalari ishlab chiqarishda foydalanish.

| Korozyon sinov natijalari | |||

| Sinov muhiti* | Korozif vazn yo'qotish, mg/sm2/yil | ||

| Konsentratsiyali reaktiv, vazn% | Harorat | SiC | SiSiC |

| 98% H2SO4 | 100°C | 1.5 | 50 |

| 50% NaOH | 100°C | 2.5 | >1000 |

| 53% HF | 100°C | <0.2 | 7 |

| 85% H3PO4 | 100°C | <0.2 | 8 |

| 70% HNO3 | 100°C | <0.2 | 0,5 |

| 45% KOH | 100°C | <0.2 | >1000 |

| 25% HCl | 100°C | <0.2 | 0.9 |

| 10% HF va 57% HNO3 | 25°C | <0.2 | >1000 |

| *Barcha kislotalarda 125-300 soatlik sinov va doimiy aralashtirish. | |||

Shandong Zhongpeng Special Ceramics Co., Ltd Xitoydagi eng yirik kremniy karbidli keramik yangi material yechimlaridan biridir. SiC texnik keramikasi: Mohning qattiqligi 9 (Yangi Mohning qattiqligi 13), eroziya va korroziyaga mukammal qarshilik, a'lo aşınma qarshiligi va antioksidlanishga ega. SiC mahsulotining xizmat qilish muddati 92% alumina materialidan 4-5 baravar uzunroq. RBSiC ning MOR qiymati SNBSC ga qaraganda 5-7 baravar yuqori, undan murakkabroq shakllar uchun foydalanish mumkin. Narxlarni aniqlash jarayoni tez, yetkazib berish va'da qilinganidek va sifat eng yaxshisidir. Biz har doim maqsadlarimizga erishishda davom etamiz va qalbimizni jamiyatga qaytaramiz.