In industrial production, many processes generate sulfur-containing waste gas. If directly discharged, it will cause serious pollution to the environment. Therefore, desulfurization has become an indispensable and important step in industrial production. Among numerous desulfurization equipment, silicon carbide desulfurization nozzles play a key role. Below is a detailed introduction for everyone.

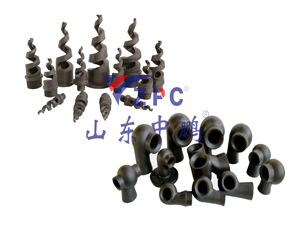

1、 Get to know the silicon carbide desulfurization nozzle

The name of the silicon carbide desulfurization nozzle indicates that its main material is silicon carbide. Silicon carbide is a new type of ceramic material that may seem unremarkable, but it has many amazing properties. It has high hardness, like a strong guardian, able to resist various wear and tear; At the same time, it also has strong corrosion resistance, and can “maintain its color” when facing corrosive substances such as acid and alkali; It can also maintain stability in high temperature environments, without easily deforming or damaging, and has excellent performance.

2、 Working principle

The working process of the desulfurization nozzle is like a carefully choreographed ‘dance’. In industrial scenarios such as power plants, sulfur-containing flue gas is discharged from pipelines, and the silicon carbide desulfurization nozzle starts working at this time. It sprays the liquid containing desulfurizer evenly, and these small droplets come into full contact with the rising sulfur-containing flue gas. Like countless little guardians, droplets quickly react chemically with harmful gases such as sulfur dioxide in the flue gas, capturing and converting them into harmless or less harmful substances, thus achieving the goal of desulfurization. In this way, the highly polluting flue gas is purified, reducing its pollution to the atmosphere.

3、 Outstanding advantages

1. Long service life: The characteristics of silicon carbide itself endow the nozzle with an extremely long service life. In harsh working environments, ordinary nozzles may quickly wear out or corrode, but silicon carbide desulfurization nozzles can work stably for a long time, greatly reducing the frequency of nozzle replacement and saving time and costs for enterprises.

2. High desulfurization efficiency: It can evenly atomize the desulfurizer into small droplets, greatly increasing the contact area with the flue gas. It’s like cutting a big cake into countless small pieces, so that each small piece can fully come into contact with the surrounding material. The desulfurizer comes into more complete contact with the flue gas, resulting in a more thorough reaction and significantly improving desulfurization efficiency.

3. Adapt to various working conditions: Whether it is high temperature and high pressure environments, or working conditions with strong corrosion and high wear, silicon carbide desulfurization nozzles can easily cope and demonstrate strong adaptability. This enables it to play an important role in different types of industrial production.

4、 Application Fields

The application of silicon carbide desulfurization nozzles is very extensive. In the power industry, it is the core component of power plant desulfurization systems, ensuring that the flue gas emitted by power plants meets environmental standards; In the steel industry, assist steel plants in processing sulfur-containing waste gases generated by sintering machines, etc; In the chemical industry, many sulfur-containing tail gases generated during chemical production processes also rely on the purification of silicon carbide desulfurization nozzles.

Silicon carbide desulfurization nozzles, with their own advantages, occupy an important position in the field of industrial desulfurization and have made significant contributions to environmental protection and sustainable industrial development.

Post time: Jul-18-2025