cov vuas ceramic industrial uas tiv taus kev hnav, cov ntaub liners

![]()

Cov tshuaj tiv thaiv bonded silicon carbide (SiSiC lossis RBSIC) yog cov khoom siv zoo tshaj plaws uas tsis yooj yim hnav, uas yog

tshwj xeeb tshaj yog rau cov khoom siv abrasive, coarse particles, kev faib tawm, concentration, dehydration thiab

lwm yam haujlwm. Nws yog dav siv hauv kev lag luam mining, kev lag luam hlau, kev lag luam ua coral, tshuaj lom neeg

kev lag luam, kev lag luam raw khoom-ua, kev sib khi tshuab, kev kho sandblasted nto thiab reflector thiab lwm yam.

Ua tsaug rau qhov nyuaj thiab kev tiv thaiv abrasive zoo heev, nws tuaj yeem tiv thaiv qhov chaw uas xav tau hnav

kev tiv thaiv, yog li ntawd thiaj li ua kom lub neej ua haujlwm ntawm cov khoom siv ntev dua.

Yuav ua li cas thiaj paub thiab nrhiav tau cov phaj, vuas, thiab cov ntaub thaiv uas tiv taus cov silicon carbide zoo?

Cov vuas vov, cov ntaub thaiv, thiab cov kav dej uas tiv taus silicon carbide tau siv ntau dua thiab ntau dua hauv kev lag luam tsuas.

Cov ntsiab lus hauv qab no yog rau koj siv ua piv txwv:

1. Cov mis thiab cov txheej txheem:

Muaj ntau cov qauv SiC hauv khw. Peb siv cov qauv German tiag tiag. Hauv kev sim tshuaj ntsuam xyuas qib siab, peb cov khoom Erosion ㎝³ poob tuaj yeem ncav cuag 0.85 ± 0.01;

2. Qhov nyuaj:

Cov vuas SiC yog tsim tawm hauv ZPC: Mohs hardness tshiab: 14.55 ± 4.5 (MOR, psi)

3. Qhov Ceev:

ZPC SiC pobzeb qhov ceev ntau yog li 3.03 + 0.05.

4. Qhov Loj thiab Qhov Nto:

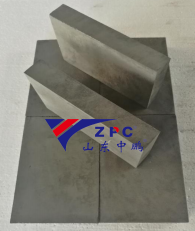

Cov vuas SiC tsim tawm hauv ZPC tsis muaj qhov tawg thiab qhov hws, nrog cov chaw tiaj tus thiab cov npoo thiab cov ces kaum zoo.

5. Cov ntaub ntawv sab hauv:

Cov ntaub thaiv/vuas uas tiv taus kev hnav ntawm silicon carbide muaj cov ntaub ntawv sab hauv thiab sab nraud zoo thiab sib xws.

If any questions, please feel free to contact us: info@rbsic-sisic.com

■Cov Lus Qhia:

| Khoom | Chav tsev | Cov ntaub ntawv |

| Kub ntawm daim ntawv thov | ℃ | 1380 ℃ |

| Qhov Ceev | G/cm3 | >3.02 |

| Qhib porosity | % | <0.1 |

| Lub zog khoov -A | Mpa | 250 (20 ℃) |

| Lub zog khoov -B | MPa | 280 (1200 ℃) |

| Modulus ntawm elasticity-A | GPa | 330 (20 ℃) |

| Modulus ntawm elasticity -B | GPa | 300 (1200 ℃) |

| Kev ua kom sov tau zoo | W/mk | 45 (1200 ℃) |

| Coefficient ntawm thermal expansion | K-1 × 10-6 | 4.5 |

| Kev Rigidity | / | 13 |

| Cov kua qaub-pov thawj alkaline | / | zoo heev |

■Muaj Cov Duab thiab Qhov Loj:

Thickness: ntawm 6mm mus rau 25mm

Cov Duab Ib Txwm: SISIC phaj, SISIC Yeeb Nkab, SiSiC Peb Qhov Txuas, SISIC Lub Luj Tshib, SISIC Cone Cyclone.

Lus Cim: Lwm qhov ntau thiab tsawg thiab cov duab muaj thaum thov.

■Ntim:

Hauv lub thawv ntawv, ntim rau hauv fumigated ntoo pallet nrog qhov hnyav 20-24MT / 20'FCL.

■Cov txiaj ntsig tseem ceeb:

1. Kev tiv thaiv zoo heev, kev cuam tshuam thiab kev tiv thaiv corrosion;

2. Zoo heev flatness thiab zoo heev kub kuj mus txog 1350 ℃

3. Kev teeb tsa yooj yim;

4. Lub neej ua haujlwm ntev dua (yog li ntawm 7 npaug ntau dua li ntawm alumina ceramic thiab 10 npaug ntau dua li ntawm

polyurethane

Tus qauv ntawm kev sib txhuam ntawm lub kaum sab xis

Thaum cov khoom siv abrasive ntws mus rau qhov chaw hnav ntawm lub kaum sab xis tsis tob lossis hla mus rau nws, hom kev hnav uas tshwm sim hauv kev sib txhuam hu ua kev swb.

Cov khoom siv silicon carbide ceramics siab heev muab kev tiv thaiv kev hnav thiab kev tiv thaiv corrosion ceramic vuas thiab hauv pem teb. Cov khoom no tau ua pov thawj tias hnav cov khoom siv hauv kev xa khoom, kev ua tiav, thiab kev khaws cia. Peb cov vuas tuaj yeem tsim nrog tuab ntawm 8 txog 45 hli. Nws yog ib qho tseem ceeb kom ntseeg tau tias koj tuaj yeem tau txais cov khoom xav tau. SiSiC: Moh qhov nyuaj yog 9.5 (Moh tshiab qhov nyuaj yog 13), nrog kev tiv thaiv zoo heev rau kev yaig thiab xeb, kev puas tsuaj zoo heev - kev tiv thaiv thiab kev tiv thaiv oxidation. Nws yog 4 txog 5 zaug muaj zog dua li nitride bonded silicon carbide. Lub neej ua haujlwm yog 5 txog 7 zaug ntev dua li alumina khoom. MOR ntawm RBSiC yog 5 txog 7 zaug ntawm SNBSC, nws tuaj yeem siv rau cov duab nyuaj dua. Hnav-resistant ceramic hauv pem teb yog conductive los ua kom zoo dua ntawm kev ua tau zoo, kev ua haujlwm zoo, txo cov nqi txij nkawm thiab nce cov txiaj ntsig.

Cov khoom siv ua los ntawm cov ...

Hnav Cov Khoom Uas Tiv Thaiv Silicon Carbide Ceramic Vuas & Cov Khoom Siv Hauv Sab Hauv:

Tiv thaiv tshuaj lom neeg

Hluav taws xob rwb thaiv tsev

Mechanical erosion & Abrasion resistant

Hloov tau

Cov txiaj ntsig ntawm Cov Vuas Uas Tiv Thaiv Tau Cov Khoom Siv Ceramic Hnav & Cov Ntaub:

Siv tau rau qhov chaw uas xav tau kev kam rau siab lossis cov ntaub nyias nyias

Siv tau los kho cov chaw uas twb muaj lawm uas yooj yim puas tsuaj

Siv tau nrog ntau txoj kev txuas xws li vuam thiab nplaum

Tsim tshwj xeeb rau cov ntawv thov tshwj xeeb

Zoo heev corrosion resistant

Kev daws teeb meem txo qis kev hnav

Tiv thaiv cov khoom txav uas raug rau qhov chaw hnav siab

Siv tau ntev dua thiab ua tau zoo dua cov kev daws teeb meem txo kev hnav

Qhov kub siab tshaj plaws siv tau txog li 1380 ° C

1, Cov nroj tsuag hlau thiab hlau: 1, lub tshuab sintering nruas sib tov hauv ob sab 2, nruas qhwv ceramic roj hmab 3, kiv cua impeller 4, disc feeder, cov khoom qhuav trough 5, coke hopper, converter bin, coke bin, cyclone plua plav collector.

2, Lub Hoobkas Fais Fab: 1. Lub qhov hluav taws xob ntawm lub pob zeb, lub pob zeb volute, lub qhov hluav taws xob ntawm lub pob zeb ceev nruab nrab, lub luj tshib hmoov yeeb nkab, lub tshuab sau hmoov av cyclone, silo, hopper 2, lub hopper thee, lub tshuab cais hmoov av ntxhib thiab zoo, lub qhov hluav taws xob ntawm lub pob zeb thee, lub hopper thauj thee 3, lub hopper thee ntawm lub choj ntes, lub hopper thee nruab nrab ntawm lub tshuab khawb thee, lub qhov hluav taws xob ntawm lub pob zeb, qhov nkag thiab qhov hluav taws xob ntawm lub tshuab cais hmoov av ntxhib thiab zoo, volute ntawm lub tshuab tso hmoov 4 Ntau hom hluav taws xob ncaj qha, swirl ntom thiab dilute kub siab hnav-resistant rau cov boilers hluav taws kub; cov kav dej ceramic composite thiab luj tshib uas hnav-resistant, cov hluav taws xob ceramic, cov kiv cua ceramic, ceramic impellers, ceramic li qub, thiab lwm yam; ntau yam khoom hnav-resistant xws li cov pob sib tsoo, cov tes tsho roller, cov discs sib tsoo, disc vuas, cov nplhaib sib tsoo, cov pob nozzle thiab lwm yam khoom hnav-resistant rau cov tshuab zeb thee ceev nruab nrab; cov kav dej, cov damper hnav-resistant thiab cov kiv cua ntawm ntau yam kev qhia tshwj xeeb rau pulverizing thiab tshem tawm tshauv; Cov pob Txhua hom zeb muaj (lossis tsis muaj) cov vuas vov, cov phaj hauv pem teb, cov yeeb nkab kauv, lub nplhaib iav, cov hlau chromium alloy qis, thiab lwm yam; lub log ntaus, phaj ntaus, tus nuv tiv thaiv, cov cuab yeej ua rog, cov khoom sib cais, cov yeeb nkab roj kub kub, thiab lwm yam rau lub tshuab cua tshuab; cov khoom siv xav tau rau ntau hom tshuab zom.

3, Lub tshuab ntawv: 1. Cov yeeb nkab thee pulverized

Cov khoom tseem ceeb thiab cov kev pabcuam: 1. Cov kav dej ceramic uas tiv taus kev hnav khaub ncaws: txhua yam khoom siv ceramic uas tiv taus kev hnav khaub ncaws thiab kub siab uas muaj cov thee sib tsoo, cov khoom seem, cov slag slurry, cov kav dej thauj mus los slurry, lub luj tshib, lub luj tshib, lub cub tawg thee sib tsoo, qhov hluav taws xob ntawm lub zeb zeb, cov hmoov av loj thiab zoo sib cais, chute, hopper, lub thoob cia khoom, lub thoob ntim khoom sib nqus ntawm kuv lub tshuab sib cais hlau nplaum; 2. Lub kiv cua ceramic uas tiv taus kev hnav khaub ncaws: txhua yam khoom siv impeller thiab volute uas tiv taus kev hnav khaub ncaws kub siab, tiv taus kev hnav khaub ncaws, tiv taus kev xeb, suav nrog lub kiv cua centrifugal, lub kiv cua axial flow, hniav zoo li qub, hniav txav tau hloov kho tau kiv cua impeller, kiv cua nqus, lub tshuab nqus hmoov, kiv cua sintering, kiv cua sib cais hmoov, kiv cua tshem plua plav, lub taub hau kiln thiab kiv cua kiln tail, thiab lwm yam; 3. Lub twj tso kua mis ceramic hauv ob sab hauv uas tiv taus kev hnav khaub ncaws thiab lub valve: hauv ob sab hauv ceramic, lub twj tso kua mis impeller, plhaub, baffle, lub luj tshib yeeb nkab, lub valve tshem tawm tshauv pneumatic thiab roj kis thiab cov khoom siv ntawm ntau yam slurry, slag slurry, mortar, tailings thiab lwm yam kev thauj mus los. 4. Cov txheej txheem ceramic uas tiv taus hnav: txhua yam txheej txheem ceramic uas tiv taus hnav thiab kub siab thiab mastic siv rau kiv cua volute, yeeb nkab luj tshib, qhov hluav taws xob zeb, yeeb nkab sib cais ntxhib thiab zoo, chute, hopper thiab valve. 5. Cov khoom siv sib cais sib nqus uas tiv taus hnav: cov khoom ntws ntawm ntau yam khoom siv ua cov khoom siv qhuav thiab ntub dej, suav nrog lub nruas sib cais sib nqus, qhov hauv qab groove, chute, pipeline, ntau yam twj tso kua mis av nkos, twj tso kua mis slurry volute, impeller, thiab pipeline conveying. 6. Kev siv tshuab txau saum npoo av: siv cov khoom siv hluav taws xob inverter pulse arc thoob ntiaj teb tshiab thiab rab phom txau arc ceev ceev, ntau yam khoom siv hlau uas tiv taus hnav thiab tiv thaiv xeb raug txau rau ntawm qhov chaw hlau substrate los tsim cov txheej txheem tiv thaiv hnav thiab tiv thaiv xeb. Nws tuaj yeem muab kev tiv thaiv zoo rau txhua yam kev xeb nruab nrab.

Shandong Zhongpeng ZPC ceramics yog ib lub tuam txhab tshwj xeeb hauv kev tsim cov khoom siv ceramics rau kev lag luam, feem ntau yog koom nrog R & D thiab kev tsim cov silicon carbide ceramics. Peb tuaj yeem ua cov khoom siv ceramic raws li koj cov duab kos, tshwj xeeb hauv kev tsim cov pas nrig ceramic loj, cov yeeb nkab ceramic, lub nplhaib ceramic, phaj ceramic, flange ceramic, ceramic nozzle, thiab cov khoom siv loj uas tiv taus hnav.

Shandong Zhongpeng Special Ceramics Co., Ltd yog ib qho ntawm cov khoom siv tshiab silicon carbide ceramic loj tshaj plaws hauv Suav teb. SiC technical ceramic: Moh qhov nyuaj yog 9 (New Moh qhov nyuaj yog 13), nrog kev tiv thaiv zoo heev rau kev yaig thiab xeb, kev puas tsuaj zoo heev - kev tiv thaiv thiab kev tiv thaiv oxidation. SiC cov khoom lub neej kev pabcuam yog 4 txog 5 zaug ntev dua li 92% alumina khoom. MOR ntawm RBSiC yog 5 txog 7 zaug ntawm SNBSC, nws tuaj yeem siv rau cov duab nyuaj dua. Cov txheej txheem hais nqe yog ceev, kev xa khoom yog raws li tau cog lus tseg thiab qhov zoo yog qhov thib ob rau tsis muaj leej twg. Peb ib txwm mob siab rau kev sib tw peb lub hom phiaj thiab muab peb lub siab rov qab rau lub zej zog.