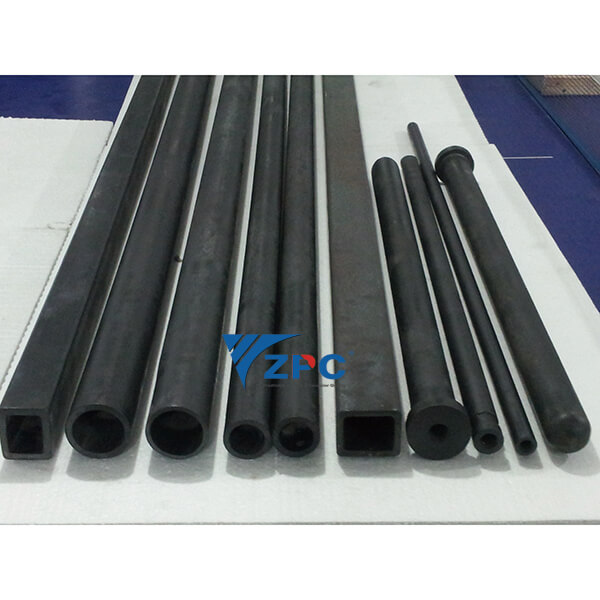

Silicon carbide beams thiab rollers rau lub kiln

Cov Tshuaj Tiv Thaiv Silicon Carbide Muaj Zog Siab Ncaj Sisic / Rbsic Rollers thiab Beams

Cov menyuam roj hmab ceramic uas siv rau kev sib xyaw ua ke yog siv rau kev lag luam roj teeb lithium, cov khoom siv porcelain txhua hnub, cov khoom siv porcelain huv, cov khoom siv ceramic hauv tsev thiab cov khoom siv sib nqus, xws li cov menyuam kiln, uas siv tau rau qhov kub siab thiab kub hnyiab zoo, thiab siv tau ntev. Nws muaj zog kub, tiv taus kev co, tiv taus kev nkag mus rau hauv qhov kub, tiv taus kev kub ntxhov, tiv taus kev nkag mus rau hauv qhov kub, tiv taus kev hnav zoo. Cov menyuam no muaj peev xwm dais tau qhov kub siab thiab siv tau ntev yam tsis muaj kev khoov, tshwj xeeb tshaj yog rau cov kilns tunnel, shuttle kiln, thiab lwm yam khoom siv hauv kev lag luam.

Cov khoom siv rau txhua hnub - siv cov khoom siv ceramics, cov khoom siv huv, Cov khoom siv Ceramic, Cov khoom siv sib nqus thiab thaj chaw kub siab ntawm lub qhov cub roller.

| Cov Khoom Siv Silicon Carbide: | ||||

| Khoom | Chav tsev | SSIC | RBSIC SISIC | R-SIC |

| Kev dawb huv | (%) | ≥ 99 | ≥90% | ≥ 99 |

| Daim ntawv thov kub | ºC | 1700 xyoo | 1380 xyoo | 1650 xyoo |

| Qhov Ceev | g/CM2 | ≥3.10-3.15 | ≥3.02 | 2.65-2.75 |

| Qhib porosity | % | ≤0.1 | ≤0.1 | |

| Qhov nyuaj | ≥92 HRA | 2400 Kg/mm2 | 1800-2000 Kg/mm2 | |

| Lub zog khoov | MPa | 400-580 | 250 (20ºC) | ≥300 |

| 281 (1200ºC) | ||||

| Lub zog tensile | Mpa | ≥200 | ≥190 | |

| modulus ntawm elasticity | GPa | 400 | 332 (20ºC) | 80-100 (20ºC) |

| 300 (1200ºC) | 90-110 (1200ºC) | |||

| Kev Ua Kub | W/mk | 100-120 | 45 (1200ºC) | 36 |

| Coefficient ntawm thermal expansion | K1X 106 | 4.2 | 4.5 | 4.6 |

| Kev Rigidity | Gpa | >25 | 13 | |

| Acid & Ikali tsis kam | Zoo heev | Zoo heev | Zoo heev | |

| Cov Khoom Siv SiC: | ||||

| Khoom | Chav tsev | OC-1 | OC-2 | MC-3 |

| SiC | (%) | ≥90 | ≥86 | ≥80 |

| Pom tseeb porosity | (%) | ≤10 | ≤13 | ≤16 |

| Qhov Ceev | g/CM2 | ≥2.66 | ≥2.63 | ≥2.6 |

| Daim ntawv thov kub | ºC | ≥1680 | ≥1620 | ≥1550 |

| Coefficient ntawm thermal expansion | aX 10-6/ºC | ≤4.8 | ≤5.0 | ≤5.5 |

| Lub zog khoov | 1200ºC | ≥45 | ≥40 | ≥30 |

Shandong Zhongpeng Special Ceramics Co., Ltd yog ib qho ntawm cov khoom siv tshiab silicon carbide ceramic loj tshaj plaws hauv Suav teb. SiC technical ceramic: Moh qhov nyuaj yog 9 (New Moh qhov nyuaj yog 13), nrog kev tiv thaiv zoo heev rau kev yaig thiab xeb, kev puas tsuaj zoo heev - kev tiv thaiv thiab kev tiv thaiv oxidation. SiC cov khoom lub neej kev pabcuam yog 4 txog 5 zaug ntev dua li 92% alumina khoom. MOR ntawm RBSiC yog 5 txog 7 zaug ntawm SNBSC, nws tuaj yeem siv rau cov duab nyuaj dua. Cov txheej txheem hais nqe yog ceev, kev xa khoom yog raws li tau cog lus tseg thiab qhov zoo yog qhov thib ob rau tsis muaj leej twg. Peb ib txwm mob siab rau kev sib tw peb lub hom phiaj thiab muab peb lub siab rov qab rau lub zej zog.