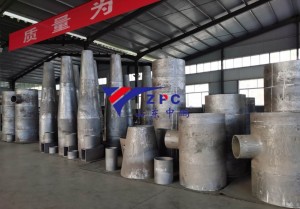

In the fields of mineral processing, chemical engineering, environmental protection, etc., cyclones are key equipment for achieving solid-liquid separation, classification, and concentration. Its core principle is simple: by generating centrifugal force through high-speed rotation, substances with different densities are layered.

However, this process poses a significant challenge to the inner walls of the equipment. High speed flowing slurry or mud often contains a large amount of solid particles, which can cause continuous erosion and wear on the vessel wall; Meanwhile, the liquid itself may be corrosive. Over time, ordinary material liners are prone to wear through, leading to frequent equipment maintenance and affecting production efficiency.

Under such harsh working conditions,silicon carbide (SiC) liningstands out with its unique performance combination. Its hardness is extremely high, and its wear resistance far exceeds that of rubber, polyurethane, and ordinary metals. It can withstand the erosion of high concentration and high flow rate slurry for a long time; Meanwhile, it has good chemical stability and can withstand corrosion from various acidic and alkaline media; In addition, the dense structure and smooth surface of silicon carbide help reduce fluid resistance, lower energy consumption, and alleviate local wear.

The most direct benefit of using silicon carbide lining is significantly extending equipment life, reducing the frequency of downtime and replacement, and thus lowering maintenance costs. The smooth surface and stable size of the inner lining also help maintain the stable separation efficiency of the cyclone and reduce product quality fluctuations caused by equipment wear. For some special working conditions, such as fine separation processes that require low metal ion pollution, the inertness and cleanliness characteristics of silicon carbide are also more advantageous.

Of course, to fully utilize the performance of silicon carbide lining, reasonable selection and installation are equally important. It is necessary to select the appropriate type and structural design of silicon carbide based on the specific properties of the medium, temperature, pressure, and operating conditions; During the installation process, it is necessary to ensure that the inner lining is tightly adhered to the equipment body to avoid early damage caused by gaps or stress concentration. When in use, try to maintain stable working conditions, avoid excessive flow and concentration fluctuations, and effectively extend the service life of the lining.

Overall, the silicon carbide cyclone liner is an ideal choice for improving the reliability and economy of separation equipment. It provides a solid guarantee for the centrifugal separation process in industrial production with excellent wear resistance and corrosion resistance.

Post time: Oct-04-2025