Ho arabela ka tsela e sa tobangsilicon carbide ceramic, e tsejoang hape e le RS-SiC, ke thepa e tsoetseng pele ea letsopa e hohetseng tlhokomelo e pharaletseng ka lebaka la ts'ebetso ea eona e ntle le mefuta e mengata ea lits'ebetso. Li-ceramic tsena li hlahisoa ka ts'ebetso e bitsoang reactive sintering, e kenyeletsang khabone le silicon tse arabelang mochesong o phahameng ho etsa silicon carbide. Thepa e hlahisoang e na le thepa e ntle ea mechini, mocheso le lik'hemik'hale, e leng se etsang hore e lokele mefuta e fapaneng ea lits'ebetso tsa indasteri.

E 'ngoe ea melemo e meholo ea liseramike tsa silicon carbide tse sintered reaction-sintered ke ho thatafala ha tsona ho ikhethang le ho hanyetsa ho tsofala. Litšobotsi tsena li etsa hore li be ntle bakeng sa tšebeliso libakeng tse thata joalo ka merafo, moo lisebelisoa li ka tsofalang le ho hoholeha ha mobu. Likarolo tsa RS-SiC tse kang li-liners tse sa tsofaleng, li-nozzle le li-impeller li sebelisoa haholo mesebetsing ea merafo ho ntlafatsa ho tšoarella le ts'ebetso ea lisebelisoa tse pepesehetseng thepa le maemo a thata. Khanyetso e phahameng ea ho tsofala ea liseramike tsa RS-SiC e thusa ho fokotsa nako ea ho se sebetse le litšenyehelo tsa tlhokomelo, e leng se etsang hore e be khetho ea pele bakeng sa lits'ebetso tsa merafo.

Ntle le ho merafo, ho kenngoa tšebetsong ha reaction-sinteredli-ceramic tsa silicon carbideli sebelisoa haholo indastering ea motlakase. RS-SiC e tsamaisang mocheso hantle le botsitso ba mocheso o phahameng li etsa hore e be thepa e loketseng likarolo lits'ebetsong tsa tlhahiso ea motlakase le kabo. Liserami tsena li sebelisoa lits'ebetsong tse kang likarolo tsa ho futhumatsa mocheso o phahameng, liphaephe tsa tšireletso ea thermocouple, le likarolo tsa ho thibela mocheso bakeng sa ho thibela mocheso oa motlakase. RS-SiC e khona ho mamella mocheso o feteletseng le ho tšoha ha mocheso, e leng se etsang hore e be khetho e tšepahalang bakeng sa likarolo tsa bohlokoa lits'ebetsong tsa motlakase le lits'ebetsong tsa motlakase.

Ho feta moo, ho se sebetse hantle ha dikeramike tsa silicon carbide tse sintered reaction-sintered ho etsa hore di lokele ho sebediswa dibakeng tse senyang. Di hanela tlhaselo ya dikhemikhale le oxidation mme di sebediswa diindastering tsa ho sebetsana le dikhemikhale, tsa tlhahiso ya metallurgical le tsa semiconductor. Dikarolo tsa RS-SiC di sebediswa ditshebetsong tse kenyeletsang dikhemikhale tse senyang, ditshipi tse qhibilihisitsweng le dikgase tse nang le mocheso o phahameng moo thepa e tlwaelehileng e ka senyehang kapa ya hloleha. Khanyetso ya ho bola le botsitso ba dikeramike tsa RS-SiC di thusa ho eketsa nako e telele ya disebediswa le ho tshepahala dibakeng tsena tse thata.

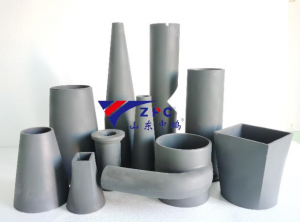

Jwalo ka moetsi e moholo ka ho fetisisa wa dikarolo tse ikgethang tsa ceramic ya silicon carbide e ikgethileng Chaena, khamphani ya rona e ikemiseditse ho fana ka dikarolo tsa RS-SiC tsa boleng bo hodimo tse entsweng ka ho kgetheha ho fihlela ditlhoko tse ikgethang tsa diindasteri tse fapaneng. Re fana ka mefuta e fapaneng ya dikarolo tsa ceramic tse entsweng ka ho nepahala, ho kenyeletswa le dijiometri tse rarahaneng le meralo e rarahaneng, ho fihlela ditlhoko tse ikgethang tsa bareki ba rona. Bokgoni ba rona ba theknoloji ya ho sintering e arabelang bo re dumella ho hlahisa dibopeho tse rarahaneng tse nang le mamello e tiileng, ho netefatsa tshebetso e ntle le bophelo ba tshebeletso ya dikarolo tsa ceramic ditshebedisong tse fapaneng.

Ho tenyetseha ha reaction-sinteredli-ceramic tsa silicon carbidee atoloha ho feta thepa ea eona ea mechine le ea lik'hemik'hale. Li-ceramic tsena li boetse li bontša ho thibela motlakase hantle, katoloso e tlase ea mocheso le ho tiea ho hoholo, e leng se etsang hore li lokele ho sebelisoa lits'ebetsong tse tsoetseng pele tsa boenjiniere. Bokhoni ba tsona ba ho boloka botsitso ba litekanyo mochesong o phahameng le libakeng tse thata bo eketsa ho hohela ha tsona indastering ea lifofane, likoloi le tšireletso. Likarolo tsa RS-SiC li sebelisoa lits'ebetsong tsa ho tsamaisa lifofane, litsamaisong tsa ho brake tsa likoloi le lits'ebetsong tsa lihlomo, moo thepa ea tsona e phahameng e thusang ho ntlafatsa ts'ebetso le ts'epo.

Ka bokhutšoanyane, liserame tsa silicon carbide tse entsoeng ka reaction-sintered li fana ka motsoako o khahlisang oa thepa e etsang hore li be tsa bohlokoa haholo lits'ebetsong tse fapaneng tsa indasteri. Ho thatafala ha eona ho ikhethang, ho hanyetsa ho tsofala, ho khanna ha mocheso le ho se sebetse ha lik'hemik'hale ho etsa hore e be khetho ea pele bakeng sa libaka tse hlokang tlhokomelo merafong, tlhahiso ea motlakase, ts'ebetso ea lik'hemik'hale le liindasteri tse ling. Jwalo ka moetsi ea ka sehloohong oa lihlahisoa tse ikhethileng.silicon carbide ceramicKa likarolo tse bōpehileng ka tsela e khethehileng, k'hamphani ea rona e ikemiselitse ho fana ka litharollo tse ncha tse sebelisang melemo e ikhethang ea RS-SiC ho fihlela litlhoko tse lulang li fetoha tsa bareki ba rona. Re tsepamisa maikutlo boleng, ho nepahala le ho iketsetsa lintho ka tsela e ikhethileng, 'me re ikemiselitse ho ntšetsa pele ts'ebeliso ea li-ceramics tsa silicon carbide tse sintered reaction-sintered masimong a fapaneng, ho kenya letsoho ho ntlafatseng ts'ebetso, bokhoni le ts'epo ea lits'ebetso tsa bohlokoa tsa indasteri.

Nako ea poso: Phupu-30-2024