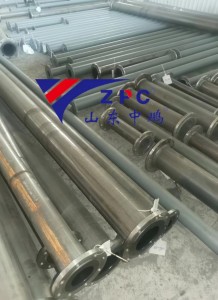

Liphaephe tsa carbide tsa silicone fetohile tharollo e ncha bakeng sa mefuta e mengata ea liindasteri ka lebaka la thepa ea tsona e phahameng. Thepa ena e tsoetseng pele e na le matla a phahameng, ho ba thata haholo, ho hanyetsa ho tsofala hantle, ho hanyetsa mocheso o phahameng, le ho hanyetsa mafome. Thepa ena e etsa hore li-tube tsa silicon carbide li be ntle bakeng sa lits'ebetso tse hlokang ho tšoarella le ho tšepahala tlas'a maemo a feteletseng. Sehloohong sena, re tla hlahloba lits'ebetso tse ngata tsa li-tube tsa silicon carbide le kamoo li fetolang indasteri kateng.

E 'ngoe ea lits'ebetso tse ka sehloohong tsa ho kenya liphaephe tsa carbide ea silicon ke indastering ea ts'ebetso ea lik'hemik'hale. Carbide ea silicon e khona ho mamella tikoloho e senyang, e leng se etsang hore e be khetho e ntle ea ho tsamaisa lik'hemik'hale tse senyang. Lisebelisoa tsa setso hangata lia bola, e leng se lebisang ho lutleng le ho qeta nako e ngata. Ka lehlakoreng le leng, ho kenya liphaephe tsa carbide ea silicon ho boloka botsitso ba eona leha e pepesehetse lik'hemik'hale tse senyang, ho netefatsa hore sistimi ea lipalangoang e bolokehile ebile e sebetsa hantle. Tšobotsi ena ha e lelefatse bophelo ba phaephe feela, empa hape e fokotsa litšenyehelo tsa tlhokomelo, e leng se etsang hore e be tharollo e theko e tlaase bakeng sa bahlahisi ba lik'hemik'hale.

Lefapheng la tlhahiso ea motlakase, liphaephe tsa silicon carbide li ntse li sebelisoa haholoanyane lits'ebetsong tsa mocheso o phahameng. Hangata lifeme tsa motlakase li sebetsa tlas'a maemo a feteletseng moo thepa ea setso e ka hlōlehang. Khanyetso ea mocheso o phahameng ea silicon carbide e e lumella ho sebetsa ka katleho libakeng tse fetang meeli ea thepa e tloaelehileng ea liphaephe. Bokhoni bona bo molemo haholo lits'ebetsong tse kang tlhahiso ea mouoane le li-exchange tsa mocheso moo kotsi ea ho senyeha ha mocheso e leng ea bohlokoa. Ka ho sebelisa liphaephe tsa silicon carbide, lifeme tsa motlakase li ka ntlafatsa bokhoni ba tsona ba ts'ebetso le ho fokotsa kotsi ea ho hloleha ha lisebelisoa.

Tšebeliso e 'ngoe ea bohlokoa bakeng sa liphaephe tsa carbide ea silicon e indastering ea merafo le ea ho sebetsana le liminerale. Ho se tsofale ha silicon carbide ho etsa hore e be sebaka se loketseng ho tsamaisa thepa e khohlang joalo ka liminerale le liminerale. Liphaephe tse tloaelehileng hangata li tsofala kapele ha li pepesehetse thepa e joalo, e leng se lebisang ho li nkeloa sebaka khafetsa le litšenyehelo tse eketsehileng tsa ts'ebetso. Leha ho le joalo, liphaephe tsa carbide ea silicon li ka mamella tlhaho ea khohlang ea thepa ena, e leng se fellang ka bophelo bo bolelele ba ts'ebeletso le nako e fokolang ea ho se sebetse. Ho tšoarella hona ho bohlokoa haholo ts'ebetsong ea merafo moo bokhoni le ts'epo li leng tsa bohlokoa ka ho fetisisa.

Lefapheng la kalafo ea metsi a litšila, liphaephe tsa silicon carbide li fumane tlhokomelo e kholo ka lebaka la ho hanyetsa mafome le ho tšoarella ha tsona. Hangata metsi a litšila a na le lintho tse fapaneng tse senyang tse ka senyang thepa ea liphaephe tsa setso ha nako e ntse e ea. Liphaephe tsa silicon carbide li fana ka tharollo e matla ho netefatsa hore metsi a litšila a tsamaisoa ka mokhoa o sireletsehileng ntle le kotsi ea ho lutla kapa ho hloleha. Ho phaella moo, matla a phahameng a liphaephe tsa silicon carbide a lumella kaho ea mabota a masesaane a liphaephe, ka hona ho fokotsa boima bohle ba sistimi ea liphaephe. Tšobotsi ena e molemo haholo ha ho lokisoa litsamaiso tse teng, moo boima e leng ntlha ea bohlokoa.

Indasteri ea li-semiconductor le eona e ruile molemo ka ho sebelisoa ha liphaephe tsa silicon carbide. Lits'ebetsong tse hlokang metsi a hloekileng haholo kapa litharollo tse itseng tsa lik'hemik'hale, botšepehi ba sistimi ea liphaephe bo bohlokoa haholo. Ho hanyetsa ha silicon carbide tšilafalong le bokhoni ba ho boloka bohloeki ho etsa hore e be e loketseng lits'ebetsong tsena. Ho phaella moo, ho thatafala ho hoholo ha silicon carbide ho netefatsa hore liphaephe li ka mamella mathata a tikoloho e nang le khatello e phahameng e tloaelehileng tlhahisong ea li-semiconductor. Ha tlhoko ea li-semiconductor e ntse e hola, karolo ea liphaephe tsa silicon carbide indastering ena e ka 'na ea atoloha.

Lefapheng la oli le khase, liphaephe tsa silicon carbide li sebelisoa haholo ka lebaka la bokhoni ba tsona ba ho mamella khatello le mocheso o phahameng. Ho ntšoa le ho tsamaisoa ha oli le khase hangata ho kenyelletsa maemo a feteletseng a ka behang botšepehi ba thepa ea liphaephe tsa setso kotsing. Liphaephe tsa silicon carbide li fana ka tharollo e tšepahalang ho netefatsa hore mehloli e lula e phalla ntle le kotsi ea ho lutla kapa ho hloleha. Ho tšepahala hona ho bohlokoa ho boloka bokhoni ba ts'ebetso le polokeho ea ts'ebetso ea oli le khase, kaha tšitiso efe kapa efe e ka fella ka tahlehelo e kholo ea lichelete.

Ka bokhutšoanyane, lits'ebetso tsa lipeipi tsa silicon carbide li akaretsa mefuta e mengata ea liindasteri, tseo e 'ngoe le e 'ngoe ea tsona e ruang molemo ho tsoa litšobotsing tse ikhethang tsa thepa ena e tsoetseng pele. Ho tloha ts'ebetsong ea lik'hemik'hale ho isa tlhahiso ea motlakase, merafo, kalafo ea metsi a litšila, tlhahiso ea semiconductor, le oli le khase, lipeipi tsa silicon carbide li ipaka e le tse fetolang papali. Matla a tsona a phahameng, ho thatafala, ho hanyetsa ho tsofala, ho hanyetsa mocheso o phahameng, le ho hanyetsa mafome li etsa hore li be ntle bakeng sa lits'ebetso tse hlokang boiteko. Ha liindasteri li ntse li tsoela pele ho batla litharollo tse ncha ho ntlafatsa ts'ebetso le ho fokotsa litšenyehelo, ho amoheloa ha lipeipi tsa silicon carbide ho lebelletsoe ho hola, ho tiisa boemo ba eona e le karolo ea bohlokoa ea meralo ea motheo ea sejoale-joale.

Nako ea poso: Hlakubele-25-2025