In the close relationship between industrial production and environmental protection, there are many seemingly insignificant but crucial equipment, and the silicon carbide desulfurization nozzle is one of them. It silently guards our blue sky and is an indispensable “behind the scenes hero” in the industrial flue gas treatment process.

What is asilicon carbide desulfurization nozzle?

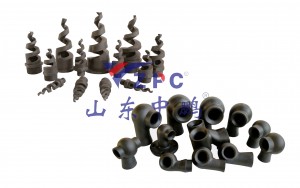

Simply put, a silicon carbide desulfurization nozzle is a component installed in a desulfurization tower specifically for spraying desulfurization slurry. Its core task is to evenly spray a slurry that can absorb sulfur dioxide from flue gas at a specific angle and shape, allowing the slurry to fully contact and react with the flue gas containing pollutants, ultimately converting harmful sulfur dioxide into harmless substances.

And ‘silicon carbide’ is the core material for manufacturing this nozzle. This material itself has the characteristics of high hardness, high temperature resistance, and corrosion resistance, which also provides a solid foundation for the nozzle to work stably for a long time in harsh industrial environments.

Why is it ‘extraordinary’?

Compared to nozzles made of other materials, the advantages of silicon carbide desulfurization nozzles are mainly reflected in the following aspects:

Super strong corrosion resistance: The slurry used in the desulfurization process is mostly acidic or alkaline, which has extremely strong corrosiveness to the equipment. Silicon carbide materials can resist the erosion of these chemicals, effectively extending the service life of nozzles and reducing replacement frequency.

Excellent wear resistance: The slurry often contains certain solid particles, which can cause wear on the inner wall of the nozzle during high-speed spraying. The high hardness characteristic of silicon carbide can effectively resist this wear and ensure the long-term stability of the nozzle spraying effect.

Stable high temperature resistance: Industrial flue gas temperatures are usually high, and silicon carbide materials can maintain structural stability in such high temperature environments, without deformation or damage due to temperature changes, ensuring the continuous and efficient desulfurization process.

How does it protect the ‘green mountains and clear waters’?

In desulfurization systems, the performance of silicon carbide desulfurization nozzles directly affects desulfurization efficiency. Its well-designed spray angle and atomization effect enable the desulfurization slurry to form sufficient and large-area contact with the flue gas inside the tower. This efficient contact enables the slurry to absorb sulfur dioxide in the flue gas more quickly and fully.

It can be said that a high-quality silicon carbide desulfurization nozzle can maximize the purification capacity of the desulfurization system, help enterprises achieve environmental emission standards more efficiently, and contribute an important force to reducing air pollution and protecting our common ecological environment.

The seemingly compact silicon carbide desulfurization nozzle, with its excellent material properties and key role in desulfurization processes, has become a truly “hardcore” equipment in the field of industrial environmental protection. It uses its own durability and efficiency to safeguard the green production of enterprises and provide solid technical support for our blue sky defense battle.

Post time: Sep-17-2025