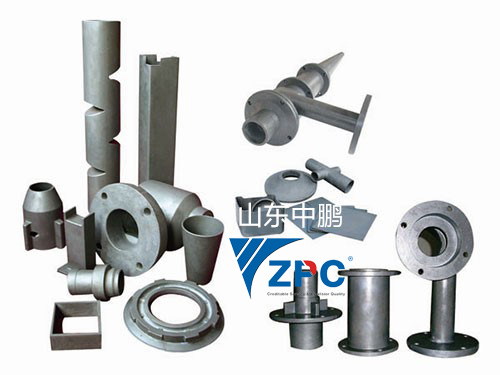

Wear resistant silicon carbide SiC ceramic parts

Reaction Bonded Silicon Carbide

ZPC Reaction Bonded Silicon Carbide (RBSC, or SiSiC) has excellent wear, impact, and chemical resistance. The strength of RBSC is almost 50% greater than that of most nitride bonded silicon carbides. It can be formed into a variety of shapes, including cone and sleeve shapes, as well as more complex engineered pieces designed for equipment involved in the processing of raw materials.

Advantages of Reaction Bonded Silicon Carbide

Pinnacle of large scale abrasion resistant ceramic technology

Designed for use in applications for large shapes where refractory grades of silicon carbide are exhibiting abrasive wear or damage from impact of large particles

Resistant to direct impingement of light particles as well as impact and sliding abrasion of heavy solids containing slurries

Markets for Reaction Bonded Silicon Carbide

Mining

Power Generation

Chemical

Petrochemical

Typical Reaction Bonded Silicon Carbide Products

Following is a list of products we supply to industries worldwide including, but not limited to:

Mircronizers

Ceramic Liners for Cyclone and Hydrocyclone Applications

Boiler Tube Ferrules

Kiln Furniture, Pusher Plates, & Muffle Liners

Plates, Saggers, Boats, & Setters

FGD and Ceramic Spray Nozzles

In addition, we will work with you to engineer whatever customized solution your process requires.

1. Ceramic tile lined pipe

This kind of ceramic tile lined pipe consist of three parts (steel pipe + adhesive + ceramic tiles), the steel pipe is made of seamless carbon steel pipe. The ceramic tiles are RBSiC or 95% high alumina, and the bonding is high temperature epoxy adhesive up to 350oC.This kind of pipe are suitable for the powder transport without tile falling off or aging working under 350oC for long time. The service life span is 5 to 10 times than normal steel pipe.

Applicable scope:These Pipes used for Pneumatic and Hydraulic Systems are suffering from high wear, high sliding and high impact, especially for the elbows. We can also design the custom pipe fittings to meet different working applications.

2. Weldable ceramic tile lined pipe

With self-locking shape ceramic tiles installed into the bend or pipe by inorganic adhesive and as well as stud welding. This solution can prevent the tiles from high abrasion as well as falling off in high temperature under 750℃.

Applicable scope:This kind of pipes is usually used for high temperature and high abration material transport system.

The ceramic tube or ceramic sleeve sintered as a whole part, and then assemble it into the steel pipe with our high-strength-temperature-resistant epoxy adhesive. The ceramic sleeve lined pipe has a smooth inner wall, excellent tightness as well as good wear and chemical resistance ability.

Advantages:

- 1.Superior wear resistance

- 2.Chemical and impact resistance

- 3.Corrosion resistance

- 4.Smooth inner wall

- 5.Easy installation

- 6.Saved maintenance time and expenditures

- 7.Longer service lifetime

4. Ceramic lined hopper and chute

Chutes or hoppers are the main equipment for material conveying and loading in the crushing system in cement, steel, coal power plant, mining and so on. With continuous conveying of particle, such as coal, iron ore, gold, aluminum etc. The chutes and hoppers are suffered very serious abrasion and impact because of such big material conveying capacity and big impact. It is also applicable to Coal, Metallurgy, and Chemical industries as feeding materials equipment.

According to the abrasion, impact and temperature, we select suitable abrasion resistant ceramic wear liners or ceramic liner to install on the inner wall of the equipment, like the mining chute, hopper, silo and material feeder, So that the equipment can prolong the lifetime.

Applied industry:The abrasion resistant ceramic wear liner chute are widely used in the cement ,steel ,chemical ,mining milling, smelting, port ,coal fired thermal power plant as wear protection equipment.

Advantages:

- 1. Superior wear resistance

- 2. Chemical and impact resistance

- 3. Erosion, acid, alkali resistance

- 4. Smooth inner wall

- 5. Easy installation

- 6. Longer service lifetime

- 7. Competitive and reasonable price

- 8. Saving maintenance time and expenditures

The material cyclone suffered serious abrasion and impact when it separated the material particle, like coal, gold, iron and ext. because of high speed material conveying. It’s very easy to wear out to leak the material from cyclone and a suitable wear protection solution for material cyclone is very necessary.

KINGCERA used the ceramic liners lined into the inner wall of the cyclone to get the wear & impact protections. It has been turned out it’s a very good wear solution for material cyclones.

Also, we can design different shape and thickness ceramic liners for the cyclones according to different working conditions. Custom cyclone can be made according to client’s drawing.

Applications:

- 1.Coal

- 2.Mining

- 3.Cement

- 4.Chemical

- 5.Steel

6. Ceramic lined air fan impeller

The fan impeller is ideal dynamic equipment which can provide the material particle conveying by wind. The material will hit and wear the fan impeller continually Because of high speed wind .So the fan impeller suffered heavy abrasion from the high speed material and repaired frequently.

ZPC used more than 10 kinds of shapes ceramics liners to line onto the surface of the impeller to form a solid wear protection layer to prevent the abrasion and impacts. It performs very well and saves the maintenance cost a lot in cement and power generation.

7. Coal Mill

The coal mill is common grinding and separating equipment in many industries, like cement, steel, coal-fired power plant. The inner wall of the mill is suffering from heavy wear and impact problems because of the grinding and hitting materials. KINGCERA can provide complete ceramic solutions from the bottom of mill to the cone of the mill. We use different ceramic liners and different installation methods to meet the different wear condition.

Advantages:

- 1.Superior wear resistance;

- 2.Smooth inner wall;

- 3.Longer service lifetime;

- 4.Lower the weight;

- 5.Saving maintenance time and expenditures.

Part of the information comes from: KINGCERA.

Shandong Zhongpeng Special Ceramics Co., Ltd is one of the largest silicon carbide ceramic new material solutions in China. SiC technical ceramic: Moh’s hardness is 9 (New Moh’s hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. SiC product’s service life is 4 to 5 times longer than 92% alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. The quotation process is quick, the delivery is as promised and the quality is second to none. We always persist in challenging our goals and give our hearts back to society.